Automatically apply for jobs with Zippia

Upload your resume to get started.

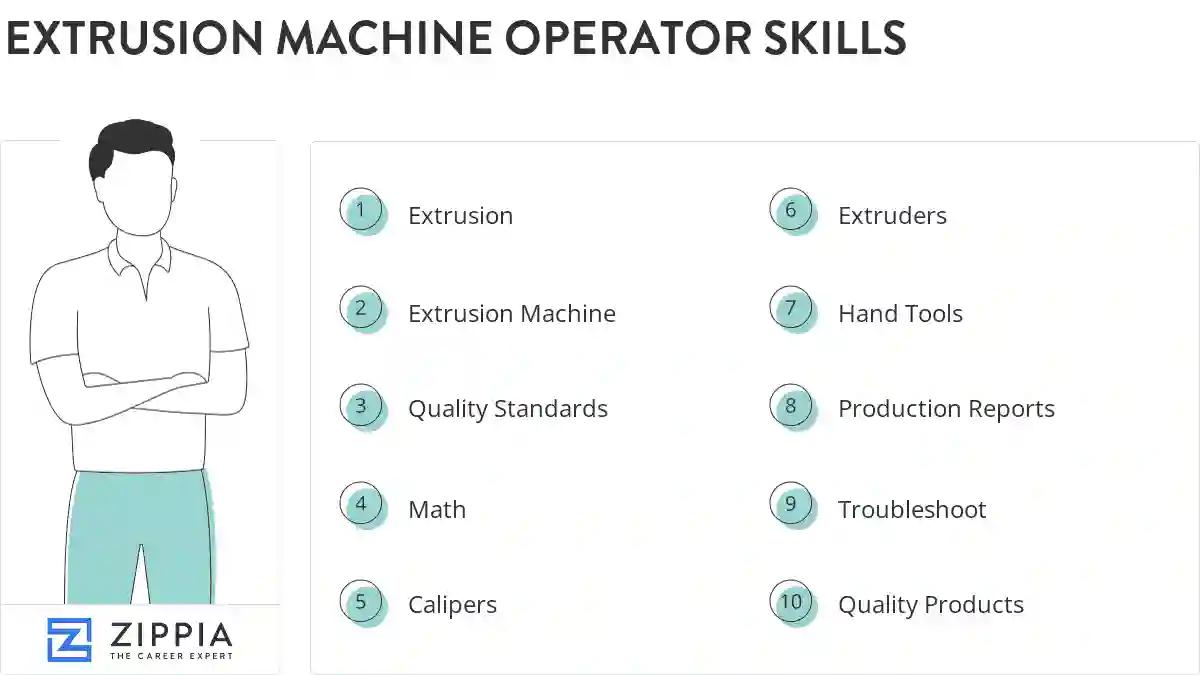

Extrusion machine operator skills for your resume and career

15 extrusion machine operator skills for your resume and career

1. Extrusion

- Developed equipment layout for extrusion department, increasing efficiency of over all production.

- Measured finished components to specifications and made necessary adjustments to the extrusion machines.

2. Extrusion Machine

- Operated an automatic extrusion machine to produce electrical automotive wire.

- Managed, operated and maintained extrusion machines.

3. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Read and understand customer specification, while maintaining quality standards.

- Review quality standards and specifications.

4. Math

- Produced and maintained accurate documentation for production reports using math and computer skills.

- Job required a variety of skills including general math and communication with management.

5. Calipers

- Maintained accuracy of machine with micrometers, calipers and measurements.

- Measure completed work pieces to verify conformance to specifications, using micrometers, gauges, calipers, or rulers.

6. Extruders

- Removed plastic rolls and sheets from extruders using hoist machinery as well as by hand.

- Monitor barrel zone emperatures, amps, and rpms of extruders to prevent jams or breakage of product.

Choose from 10+ customizable extrusion machine operator resume templates

Build a professional extrusion machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your extrusion machine operator resume.7. Hand Tools

- Set up, operate or tend machines using hand tools; adjust feed mechanisms to set the feed rates.

- Selected and installed machine components such as dies, molds and cutters using hand tools and measuring devices.

8. Production Reports

- Maintained production reports and personnel records.

- Provided production reports of the product produced as required.

9. Troubleshoot

Troubleshooting is the process of analyzing and fixing any kind of problem in a system or a machine. Troubleshooting is the detailed yet quick search in the system for the main source of an issue and solving it.

- Trained various employees to operate and troubleshoot various manual and automated machines, furthering company growth.

- Machine Operator Duties: Operate machinery in fast-paced environment; troubleshoot machines in prevention of downtime, preventative maintenance of machinery.

10. Quality Products

A quality product satisfies the client's intended need and matches the cost the consumer paid for it.

- Followed manufacturing process procedures resulting in production of quality products that exceed customer expectations.

11. Minor Maintenance

- Performed some minor maintenance task including electrical and mechanic work.

- Operated Machine along with minor maintenance and daily cleaning Ensured quality of product met customer standards

12. Machine Operation

- Monitor machine operations and observe lights and gauges in order to detect and prevent malfunctions.

- FIELD OF INTERESTS Machine operations dxcx

13. Safety Measures

- fill out run sheet and call for quality check to ensure safety measures.

14. Grinders

- Operated heavy duty lathes, boring machines and mills, planers, shapers and grinders.

15. PPE

Personal protective equipment is an item of protective clothing such as goggles, helmets, or other garments meant to protect the body from injury.

- Wear proper PPE and follow all SOP procedures.

- Work around extreme heat Safety PPE

5 Extrusion Machine Operator resume examples

Build a professional extrusion machine operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your extrusion machine operator resume.

What skills help Extrusion Machine Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of extrusion machine operator skills to add to your resume

The most important skills for an extrusion machine operator resume and required skills for an extrusion machine operator to have include:

- Extrusion

- Extrusion Machine

- Quality Standards

- Math

- Calipers

- Extruders

- Hand Tools

- Production Reports

- Troubleshoot

- Quality Products

- Minor Maintenance

- Machine Operation

- Safety Measures

- Grinders

- PPE

- Forklift Training

- Tape Measure

- Safety Rules

- Quality Issues

- Production Lines

- Production Equipment

- CNC

- Production Schedules

- Air Pressure

- Lockout Tagout

- Customer Specifications

- Mechanical Problems

- Quality Inspection

- Computer System

- PVC

- RAN

- Synthetic Materials

- Color Changes

- Product Specifications

- Doff

- Production Data

- Mathematics

- Assembly Line

- Safety Regulations

- Hoists

- Production Process

- Machine Functions

- Production Logs

Updated January 8, 2025