Automatically apply for jobs with Zippia

Upload your resume to get started.

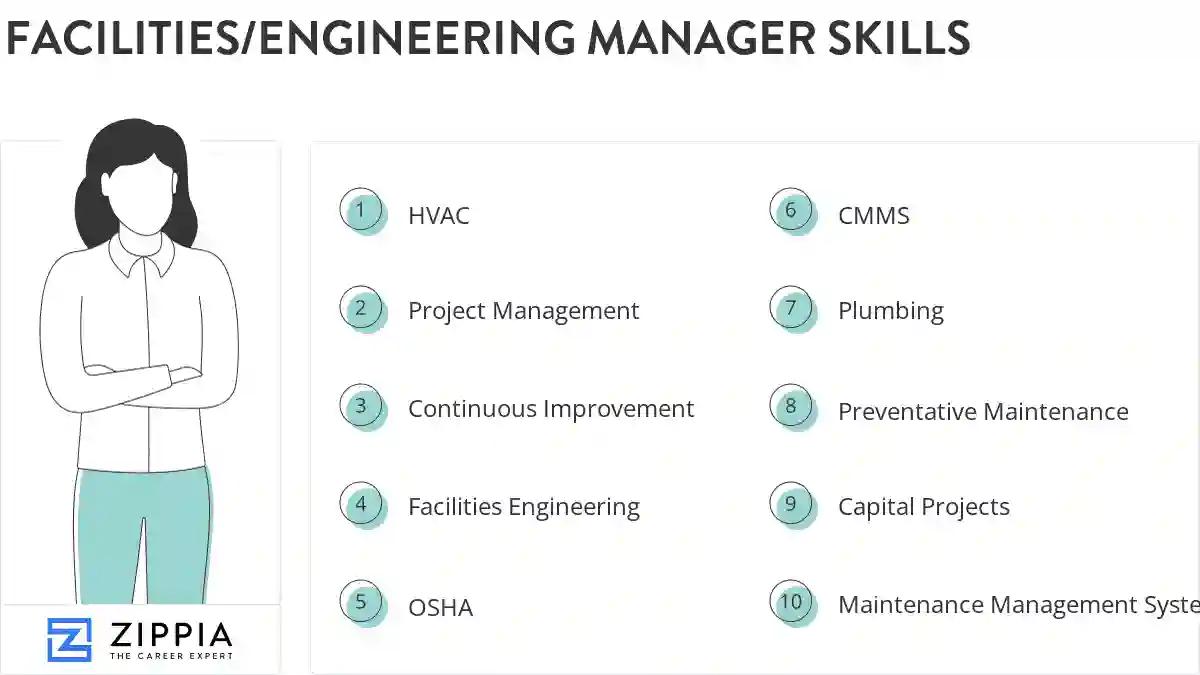

Facilities/engineering manager skills for your resume and career

15 facilities/engineering manager skills for your resume and career

1. HVAC

- Administered complex capital improvement projects including clean room retrofits, laboratory compressed air and nitrogen systems, HVAC improvements.

- Maintain facility HVAC equipment using Building Automation System to monitor equipment and make recommendations for energy reduction projects.

2. Project Management

- Handled total project management including cost/schedule scope/quality control/permitting/documentation.

- Recruited operating staff of 27 and established training programs with skill quality levels exceeding corporate and project management expectations.

3. Continuous Improvement

Continuous improvement is an ongoing process of improvement of products, services, and processes with the help of innovative ideas. It is an organized approach that helps an organization to find its weaknesses and improve them.

- Direct and manage all maintenance activities including: maintenance employee development, scheduling, continuous improvement, individual and departmental goals.

- Managed Continuous Improvement Projects, engaged in designing new or changes in process flow and layouts.

4. Facilities Engineering

- Direct supervision of site manufacturing and facilities engineering, site facilities maintenance and product equipment design engineering.

- Provided leadership and direction to facilities engineering, facilities maintenance, and facilities operations.

5. OSHA

- Coordinated with O&M / NASA Safety QC personnel, to assure compliance with DFRC and OSHA requirements.

- Evaluated and implemented changes and additions to equipment and processes to support strict company and OSHA safety guidelines.

6. CMMS

- Developed maintenance and reliability programs and installed CMMS.

- Oversee all preventative and corrective maintenance at the facility, through the computerized maintenance management system (CMMS).

Choose from 10+ customizable facilities/engineering manager resume templates

Build a professional facilities/engineering manager resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your facilities/engineering manager resume.7. Plumbing

- Repaired and maintained furniture, flooring, painting, plumbing, F&B equipment, electrical, etc.

- Monitored the maintenance of entire building (includes plumbing, electrical, air conditioning, and heating).

8. Preventative Maintenance

- Developed the preventative maintenance program for the organization to proactively manage all building systems and production equipment to drive operational excellence.

- Developed standard operating procedures for preventative maintenance and regulatory compliance to establish operational consistency and better manage budgetary exposures.

9. Capital Projects

A capital project is a long-term project carried out by professional teams to build, improve, maintain or develop a huge project that will help improve the asset of a city. This project involves a significant and constant flow of investments. A capital project can be new construction, the purchase of land or property, leasing a property, the renovation of an existing building, or the purchase of new equipment.

- Developed and managed capital projects including industrial equipment procurement and installations.

- Direct accountability for facilities maintenance personnel and capital projects engineering staff.

10. Maintenance Management System

- Implemented engine room automation, computerized maintenance management system (CMMS) and comprehensive roof replacement program.

- Established a Computerized Maintenance Management System capable of tracking and scheduling assets' maintenance requirements and inventory.

11. Facility Operations

- Negotiated with utilities & vendors for facility operations contract renewals for best-cost results.

- Coordinated/managed technical support services to provide superior management of facility operations.

12. CAD

- Managed CAD department, centralized engineering document filing and control system.

- Organized and trained personnel in proper procedures for blueprint reading, upgrading, and correcting, using Auto Cad.

13. Electrical Systems

- Managed mechanical/electrical systems maintenance support, building & grounds, janitorial services and office rearrangements.

- Facilitated in-depth thermo-graphic analysis of all normal and emergency electrical systems.

14. Maintenance Program

- Work with upper management to implement improved schedule maintenance program resulting in cost savings and increased customer satisfaction.

- Designed and implemented planned maintenance programs, and upgraded electrical distribution, control and utilities conservation programs.

15. Fire Protection

- Install, commission, troubleshoot, and inspect fire protection and detection equipment on Maritime Vessel.

- Repair of Electrical, Mechanical, and Fire protection systems in large commercial vessels.

5 Facilities/Engineering Manager resume examples

Build a professional facilities/engineering manager resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your facilities/engineering manager resume.

What skills help Facilities/Engineering Managers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

What skills stand out on facilities/engineering manager resumes?

Dr. John Ballato

J. E. Sirrine Endowed Chair and Professor, Clemson University

Another point about skills that stand out is a simple one - do your homework. There are few things more irritating than receiving a resume or email asking for a job, and the student clearly didn't care enough to look up what we do. The resume is a copy and paste and isn't personalized to the specific position, Group, or company. That stands out like a sore thumb.

What soft skills should all facilities/engineering managers possess?

Dr. John Ballato

J. E. Sirrine Endowed Chair and Professor, Clemson University

What hard/technical skills are most important for facilities/engineering managers?

Dr. John Ballato

J. E. Sirrine Endowed Chair and Professor, Clemson University

What facilities/engineering manager skills would you recommend for someone trying to advance their career?

Associate Professor, Pennsylvania State University - Abington

What technical skills for a facilities/engineering manager stand out to employers?

Professor and Assistant Chair, Ohio University

List of facilities/engineering manager skills to add to your resume

The most important skills for a facilities/engineering manager resume and required skills for a facilities/engineering manager to have include:

- HVAC

- Project Management

- Continuous Improvement

- Facilities Engineering

- OSHA

- CMMS

- Plumbing

- Preventative Maintenance

- Capital Projects

- Maintenance Management System

- Facility Operations

- CAD

- Electrical Systems

- Maintenance Program

- Fire Protection

- GMP

- Maximo

- Construction Projects

- Mechanical Systems

- Technical Support

- Facility Maintenance

- Facilities Management

- PLC

- Facilities Equipment

- Plant Operations

- Sops

- NFPA

- Construction Management

- Cost Estimates

- MEP

- Process Improvement

- Lean Manufacturing

- Control Systems

- Service Contracts

- R

- ISO

- Equipment Maintenance

- BMS

- Production Equipment

- Snow Removal

- Direct Reports

- EHS

- Sigma

- Cooling Towers

- TPM

- FDA

- Water Treatment

- Emergency Generators

- Cost Savings

Updated January 8, 2025