Automatically apply for jobs with Zippia

Upload your resume to get started.

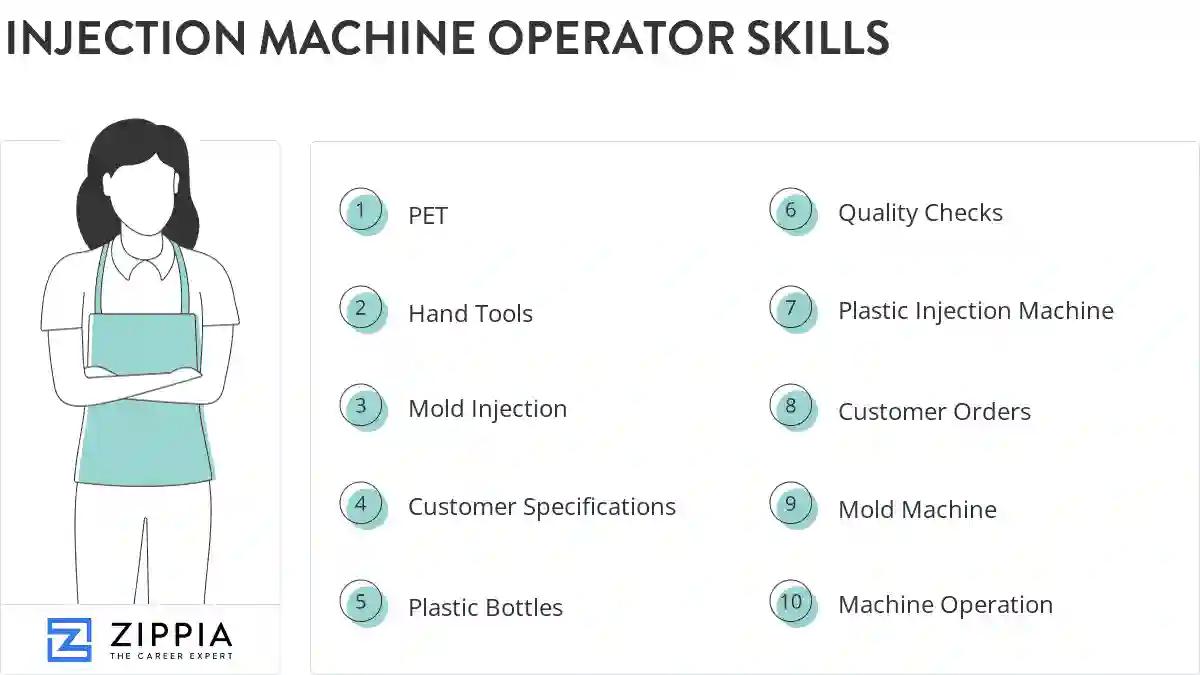

Injection machine operator skills for your resume and career

15 injection machine operator skills for your resume and career

1. PET

- Operate multiple injection press machines changing process set up of injection presses, plastic resin/ pet, as needed.

2. Hand Tools

- Removed finished products from dies with hand tools.

- Operated molding machines and auxiliary equipment including hand tools.

3. Mold Injection

- Operated progressive punch press and hot mold injection machines continually maintaining production standards.

- Operated the mold injection machine which made plastic parts for the automobile industry.

4. Customer Specifications

A Customer Specification is a document that describes the general requirement of an expected service from a contractor. It outlines the key requirements of the customer. Customer specifications should be written in simple and general language so that the contractor clearly understands the expectations of the customer. It is also known as a User Specification.

- Ensured that boxes were properly labeled to customer specifications.

- Located and prepared orders for shipping according to customer specifications and regulations, maintained delivery data accurate and up to date.

5. Plastic Bottles

- Catch hot plastic bottles fresh from blow molder.

6. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Performed daily and hourly quality checks on multiple machines.

- Conducted quality checks by monitoring ink and water for appropriate levels and intensity based on customer specifications.

Choose from 10+ customizable injection machine operator resume templates

Build a professional injection machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your injection machine operator resume.7. Plastic Injection Machine

- Operate Plastic Injection Machines * Perform Quality Control Checks

- Operated and trim parts coming off plastic injection machinery Inspect and box all parts onto skids Keep working area safe and clean

8. Customer Orders

- Reviewed master production schedule and work orders, established priorities for specific customer orders and revised according to work order specifications.

- Maintain ongoing customer contact, and regular communications with appropriate internal departments in support of customer orders.

9. Mold Machine

- Operated hydraulic and electric injection mold machines.

- Operate plastic injection mold machine, inspect parts, Clean and Pack parts for shipping.

10. Machine Operation

- Certified Machine Operator Plastic Injection Molding Machine Operation, Material handling, Hop fill, In-process inspection.

- Observed machine operations, cleared jams and restarted machine or notified correct personnel.

11. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Set up and operated manual table routers before advancing into operation of CNC automated machinery.

- Operated a CNC mill making various automotive parts while meeting company expectations

12. Quality Inspection

Quality inspections are measures to verify, examine or test various properties of one or more products and relate the results to the requirements to confirm compliance with the manufacturing processes. This is carried out to discover product defects and inform the management team for a decision on whether to approve or reject the product release.

- Operated plastic injection molding machine, performed quality inspection, packaged and labeled parts utilizing automatic labeling machine.

- Document production by logging into company computer system and completing written downtime and quality inspection log sheets.

13. Drill Press

A drill press refers to a device used to produce holes in hard substances. When drilling the holes, you need to clamp the workpiece on a table and hold the drill in a rotating spindle and feed it into the workpiece.

- Company Operated drill press and utilized measuring devices.

- Operated piranha shearing machine and Cincinnati drill press

14. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Ensured that every part packed adhered to Honda's strict quality standards.

- Adhered to safety and quality standards.

15. Continuous Operation

- Operated aluminum Zinc Die casting machine, observed continuous operation of machine to ensure products met specifications.

- Implemented preventative maintenance techniques to ensure tools were in continuous operation, promoting efficiency and productivity.

5 Injection Machine Operator resume examples

Build a professional injection machine operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your injection machine operator resume.

What skills help Injection Machine Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of injection machine operator skills to add to your resume

The most important skills for an injection machine operator resume and required skills for an injection machine operator to have include:

- PET

- Hand Tools

- Mold Injection

- Customer Specifications

- Plastic Bottles

- Quality Checks

- Plastic Injection Machine

- Customer Orders

- Mold Machine

- Machine Operation

- CNC

- Quality Inspection

- Drill Press

- Quality Standards

- Continuous Operation

- Automatic Machines

- Rubber Injection

- Package Product

- Hoists

- Production Runs

Updated January 8, 2025