Automatically apply for jobs with Zippia

Upload your resume to get started.

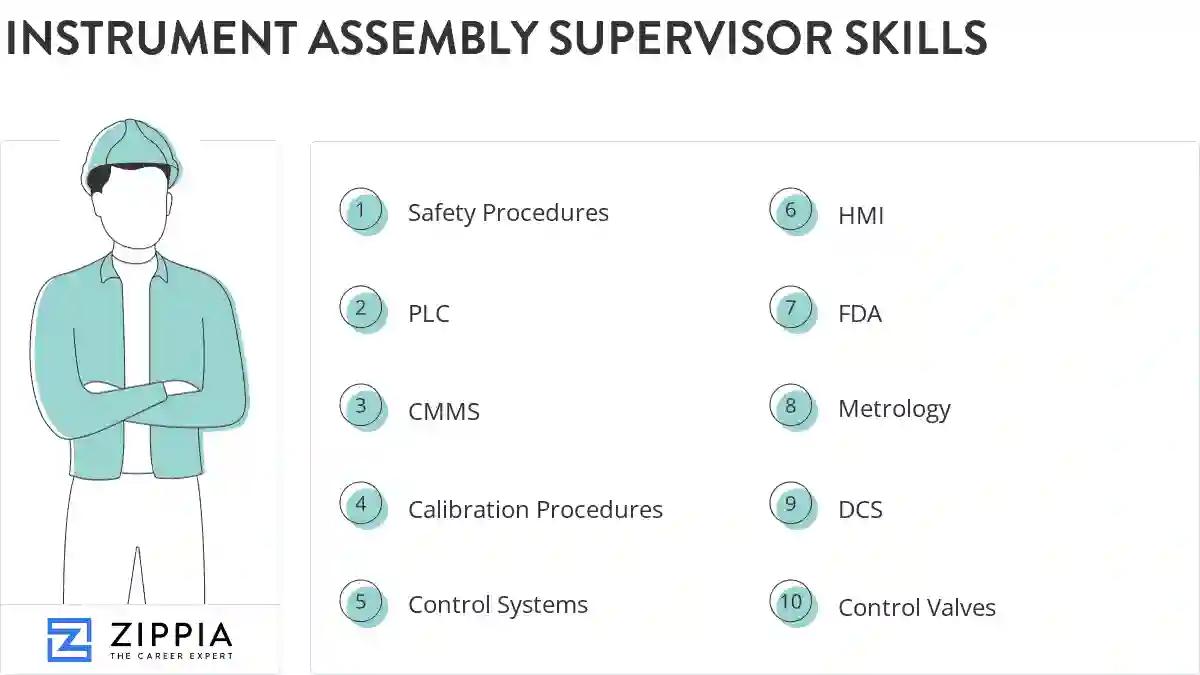

Instrument assembly supervisor skills for your resume and career

15 instrument assembly supervisor skills for your resume and career

1. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Worked closely with inter-department and lead contractors to ensure all work is performed within the company standards and safety procedures.

- Attend and Perform toolbox talk to ensure that all Safety guidelines and safety procedures are followed.

2. PLC

- Delegate to the administration, correction and detection of faults in the SIL- PLC with RS- Logix 5000.

- Trained and developed technical support for new technology introduction, including robotics and PLC controls implementation.

3. CMMS

- Performed technical review and administered quality checks for all maintenance and calibration work in both SAP PM CMMS and CalMan CCMS.

- Input and manage data in SAP and Blue Mountain CMMS databases.

4. Calibration Procedures

Calibration procedures are controlled documents that provide methods for evaluating and verifying performance characteristics, specifications, or tolerances for a model of measuring or testing equipment.

- Developed and implemented equipment maintenance/calibration procedures.

- Generated and revised calibration procedures.

5. Control Systems

- Worked as an instrumentation, electrical, and control systems supervisor in a recycle paper mill.

- Well versed with following control systems and instruments.

6. HMI

A human-machine interface is a dashboard or user interface that connects an operator to a device, system, or machine.

- Use of HMI terminals to record instrument readings from field equipment and standards along with the required GMP documentation.

- Program PLC, HMI and SCADA systems.

7. FDA

The Food and Drug Administration (FDA) is a division of the US Department of Health and Human Services that regulates the production and sale of food, pharmaceutical products, medical equipment, and other consumer goods, as well as veterinary medicine. The FDA is now in charge of overseeing the manufacture of products like vaccines, allergy treatments, and beauty products.

- Revised all calibration certificates in order to maintain all calibration records in compliance with the FDA standards.

- Performed periodic audits to engineering suppliers in order to assure compliance with FDA standards.

8. Metrology

Metrology is the scientific study of measurement. It establishes the understanding of units which is crucial to linking human activity.

- Performed metrology tests and inspections on products for pressure, temperature, torque, weights, analog and digital meters.

- Retained by a leading biotechnology company to serve as the supervisor of the Metrology department.

9. DCS

A DSC, Distributed Control System, is a specially computerized design control system that autonomously coordinates several subsystems located around the entire manufacturing plant or industrial process through a high-speed communication network where top-down coordination and control are utmost for efficiency.

- Instrument field engineering and construction supervision on a Turn Key project of DCS installation for an Oil Refinery.

- Performed DCS system Hot change over and successfully completed without trip or plant shutdown.

10. Control Valves

A control valve is a device that uses power to manipulate and regulate the flow of fluids. A control valve is the most common final control element in the industry since it is a critical part of a control loop.

- Control Valves: Various types of control valves.

- Control valves, on / off valves, & Motor Operated valves.

11. Transmitters

- Level Transmitters: Radioactive, Differential pressure, Radar type, Float and Torque tube(Level-troll).

- Installed Level, Pressure, Flow transmitters for gas storage Managed 2 in-house service technicians.

12. Control Loops

- Performed basic configuration including simple control loops, alarm reporting, and design of graphical displays.

- Start Up/ Commissioning Control Loops/ Systems at Watts Bar Nuclear Power Plant Unit 2 for Williams Plant Services.

13. CEMS

- Sample Panels & CEMS (Continuous Emissions Monitoring Systems), also tank farms & water treatment instruments.

14. ESD

- Test, checkout and calibrate process control system and associated instrumentation, (DCS, ESD).

- Check the logic of ESD system and modify the logic refer to philosophy of this process.

15. Instrument Calibration

- Field experience in industrial instrument calibration, loop checks, spanning of instruments, instrument pre-commissioning, commissioning, and startup.

- Incorporated instrument calibration and maintenance into existing PM schedule.

What skills help Instrument Assembly Supervisors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of instrument assembly supervisor skills to add to your resume

The most important skills for an instrument assembly supervisor resume and required skills for an instrument assembly supervisor to have include:

- Safety Procedures

- PLC

- CMMS

- Calibration Procedures

- Control Systems

- HMI

- FDA

- Metrology

- DCS

- Control Valves

- Transmitters

- Control Loops

- CEMS

- ESD

- Instrument Calibration

- MCC

- AUG

- SCADA

- I/O

- Function Test

- HVAC

- ITP

- Maximo

Updated January 8, 2025