Automatically apply for jobs with Zippia

Upload your resume to get started.

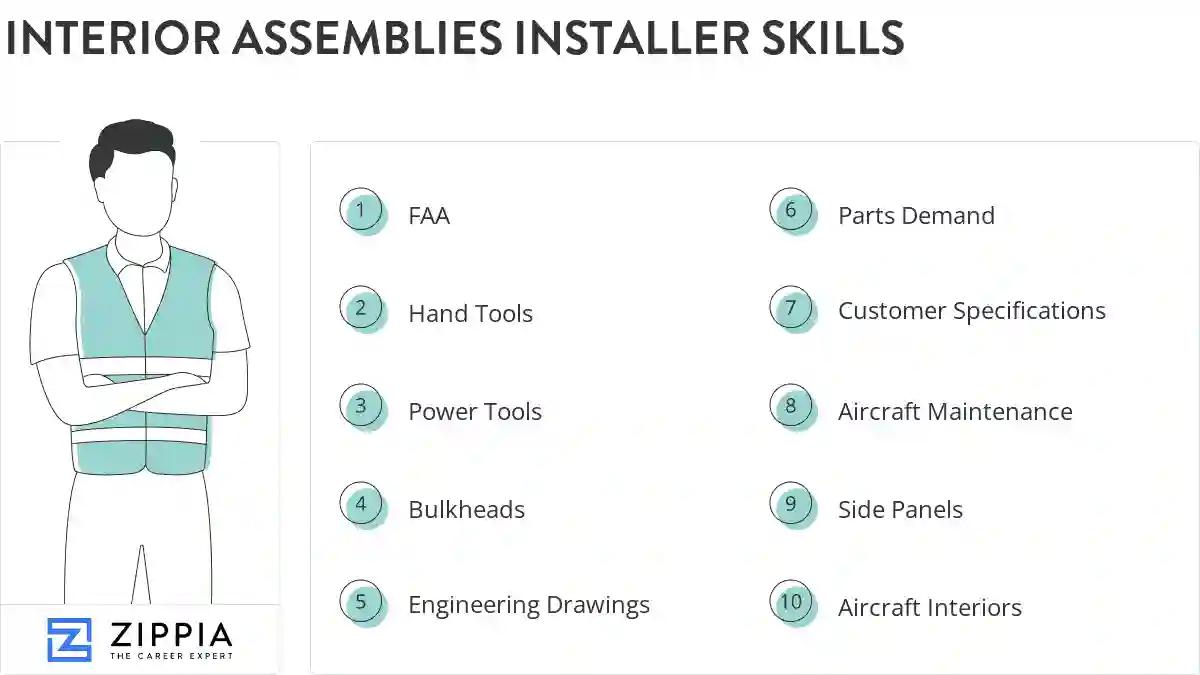

Interior assemblies installer skills for your resume and career

14 interior assemblies installer skills for your resume and career

1. FAA

FAA (Federal Aviation Administration) is an aviation regulatory body in the USA.

- Completed corresponding FAA certified paperwork and research necessary for all Learjet installations.

- Obtained Certified Aircraft Repairman Certificate through the FAA.

2. Hand Tools

- Fit, install, and secure material on seat frames, using hand tools, power tools, glue and/or staples.

- Assembled floors, panels, seats, and doors using hand tools, pneumatic tools and electrical tools for UPS trucks.

3. Power Tools

- Drilled, reamed, countersunk, trimmed and filed parts and assemblies, using handtools and power tools.

- Utilized many different hand, pneumatic and power tools.

4. Bulkheads

- Installed galleys, lavs, side ledges, bulkheads and doors.

- Performed Fiberglassing of BulkHeads, Deco Panels and FloorBoard Mods and repairs.

5. Engineering Drawings

Engineering drawings are technical drawings that tell about the requirements for engineering components or equipment. Such drawings have standardized languages and symbols. There are multiple types of engineering drawings such as isometric drawing, orthographic or multiview drawing, schematic drawings, one view, and two view drawings, etc.

- Followed engineering drawings and manufacturer processes to successfully locate interior cabinetry, components and furnishings.

- Modified aircraft structures, systems, and components, following strict adherence to engineering drawings and technical publications.

6. Parts Demand

- Used the material tracking system to create parts demand, track squawks and to sign-off work.

- Utilized material tracking system to create parts demand and track

Choose from 10+ customizable interior assemblies installer resume templates

Build a professional interior assemblies installer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your interior assemblies installer resume.7. Customer Specifications

A Customer Specification is a document that describes the general requirement of an expected service from a contractor. It outlines the key requirements of the customer. Customer specifications should be written in simple and general language so that the contractor clearly understands the expectations of the customer. It is also known as a User Specification.

- Modify, repair, or fabricate existing interior components to comply with customer specifications.

- Remove, refurbish, and install pre customer specifications.

8. Aircraft Maintenance

- Assist technicians, under supervision, with aircraft maintenance requirements

- Installed cabinets, carpets, seats, Electrical, and preformed aircraft maintenance.

9. Side Panels

- Removed headliner, sidewalls, side panels, armrest, seats, cabinets, carpet and all vanities.

- Fit panels and windows, cabin head liners, upper sidewalls, lower side panels and hatch panels.

10. Aircraft Interiors

- Manufactured, fit and installed aircraft interiors per aircraft drawings and blueprints specifications.

- Fit and installed aircraft interiors using planning books and blueprints.

11. Air Tools

- Operated Buzz Saw, Cutting Torch, Cat auger drill and various hand and air tools.

- Installed seat tracks per blue prints, measuring, drilling and installing bolts with air tools.

12. Refurbishment

- Refurbish /recover lavatories and galley's.

- Remove and reinstall interiors on all big inspections and refurbishments and help with the refurbishment

13. Stainless Steel

Stainless steel is an alloy of iron, chromium, carbon, and some other metals with corrosion-resistant properties. The components of steel include less than 1% carbon, 1% manganese, and small quantities of other elements such as phosphorus, silicon, sulfur, and oxygen. Iron and carbon are the two essential components of steel. Stainless steel is resistant to tarnishing and rust.

- Drill, tap, countersink, and rivet stainless steel and mild steel.

14. VIP

A VIP is an important or unique person accorded with the highest respect and special privileges in any given and environment. It's an acronym for Very Important Person and such a person naturally wields Influence in society, is very popular, and has a higher social status.

- Fitted and installed various interior items on privately owned VIP aircraft.

- Performed structures and VIP interiors on Airbus designed by customer.

What skills help Interior Assemblies Installers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of interior assemblies installer skills to add to your resume

The most important skills for an interior assemblies installer resume and required skills for an interior assemblies installer to have include:

- FAA

- Hand Tools

- Power Tools

- Bulkheads

- Engineering Drawings

- Parts Demand

- Customer Specifications

- Aircraft Maintenance

- Side Panels

- Aircraft Interiors

- Air Tools

- Refurbishment

- Stainless Steel

- VIP

Updated January 8, 2025