Automatically apply for jobs with Zippia

Upload your resume to get started.

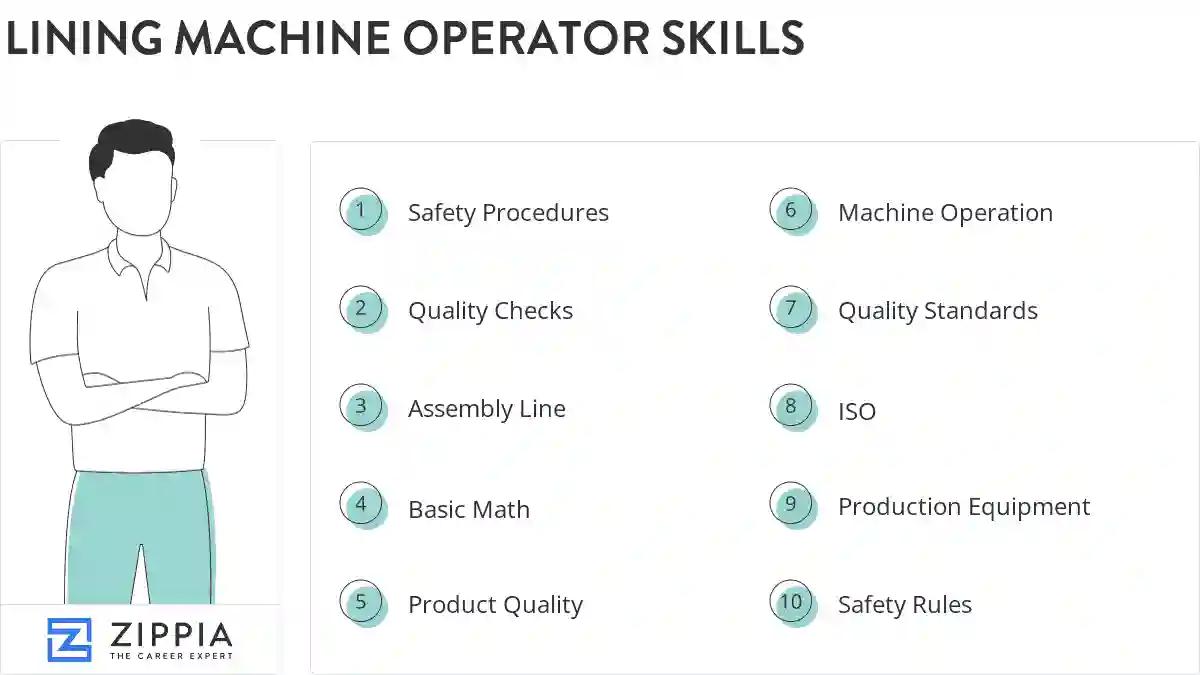

Lining machine operator skills for your resume and career

15 lining machine operator skills for your resume and career

1. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Developed thorough understanding of safety procedures

- Line worker must also be able to stand long periods of time and follow safety procedures for OSHA.

2. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Developed a driven need to update quality checks and procedures to assure the high standards needed in today's market.

- Load parts* Unload parts* Quality checks* Leak/Flow testing* Gage part to specs* Fork truck driver* Hoist operator* CNC- fix machines

3. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Operated computerized machine to filled containers, labeled product on fast-paced assembly line.

- Followed prescribed safety protocol and assisted other assembly line crew members as needed.

4. Basic Math

- Earned the Line Leader position after only 2 months of gaining employment Skills Used Basic math Team leading

- Followed production instructions and utilized a computer and calculator to aid in basic math calculations.

5. Product Quality

Product quality is the basic element of a business. It means to add features in a product or service in such a way that it meets the needs and wants of the customers. Enhancing the product quality also means improve the goods from any existing defects to ensure customer satisfaction.

- Manufactured product while maintaining and improving product quality.

- Monitor product quality and organize problems/ defects with process, equipment and products and follow through on solutions/corrections.

6. Machine Operation

- Refueled engine, lubricated machine parts and monitored machine operations to ensure optimum performance.

- Set up and adjusted manufacturing and processing machines, using charts, oral instructions and knowledge of machine operation.

Choose from 10+ customizable lining machine operator resume templates

Build a professional lining machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your lining machine operator resume.7. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Shrink wrapped flowers to ensure quality standards Line Lead/Machine operator

- Relieved co-workers on the line when necessary - Ensured the products on the production line met quality standards.

8. ISO

- Utilize Quality First principles to inspect and approve finished goods (QS 9000 & ISO 9000).

- Experience with ISO 9001 and Lean Manufacturing.

9. Production Equipment

Production equipment in limited terms is used to define any type of machinery or equipment used in the production of a video or film. Basic production equipment includes a camera, tripod, lighting kit, camera light, short term microphone, light reflector, boom pole, shock mount, audio cables, wireless microphone, headphones, portable digital audio recorder, camera lenses, extra batteries, external hard drive, and DSLR shoulder mount rig.

- Performed routine preventative maintenance and emergency repairs on high volume production equipment.

- Demonstrated creative problem solving skills in working with production equipment, employee issues and organizational protocols.

10. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Comply with and fully understand all OSHA and company safety rules.

- Maintained a clean workspace Followed all safety rules and regulations including use of PPE to ensure a safe environment.

11. Pallet Jack

- Licensed Operator of Powered Industrial Trucks: Stand Up Forklift, Sit Down Forklift & Pallet Jack

- Possessed certification in LOTO, Turret Press Operation, Pallet Jack Operation and Brake Press Operation.

12. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Trained with PLC and CNC controls along with Computer Aided Quality check system that uses Calipers and Depth Gauges.

- Trained in the set up, tool change, and operation of Fuji CNC lathe machine.

13. GMP

GMP stands for Good Manufacturing Practice. It is a system that ensures that all products like food, beverages, and medicinal drugs that are produced comply with the quality standards. It helps in minimizing the risks and hazards that cannot be eliminated after the testing of final products.

- Experienced with standards of daily operations (OSHA requirement on minimum/maximum practices, /ISO, GMP, PPE and MSDS).

- Ensured compliance with all regulations including GMP'S, OSHA and Universal and product licenses requirements.

14. Production Schedules

The project plan of a film or a documentary that highlights how a production budget will be spent over a given period until its completion is called a production schedule. The scheduling process starts with writing and analyzing the script, which is then broken down to determine and allocate the budget for each scene. The production schedule also includes several elements of the film including; cast actors, special effects, wardrobe, special equipment, stunts, extras, silent bits, production equipment, and many others.

- Lead group of production associates to meet daily production requirements according to production schedule and customer product needs.

- Read work orders and production schedules to determine specifications, such as product and material.

15. HACCP

- Follow all HACCP program requirements to prevent system failures and ensure compliance with all Good Manufacturing Practices.

- Document accurate completion of batch HACCP log sheets.

5 Lining Machine Operator resume examples

Build a professional lining machine operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your lining machine operator resume.

What skills help Lining Machine Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of lining machine operator skills to add to your resume

The most important skills for a lining machine operator resume and required skills for a lining machine operator to have include:

- Safety Procedures

- Quality Checks

- Assembly Line

- Basic Math

- Product Quality

- Machine Operation

- Quality Standards

- ISO

- Production Equipment

- Safety Rules

- Pallet Jack

- CNC

- GMP

- Production Schedules

- HACCP

- Extrusion

- Safety Regulations

- Safety Standards

- Line Production

- Assembly Process

- PPE

- Routine Maintenance

- Production Reports

- Wrap Machine

- Safety Guidelines

- Customer Specifications

- Hoists

- Leadership

- Production Process

- QA

- FDA

- Clean Machines

- Lockout Tagout

Updated January 8, 2025