Automatically apply for jobs with Zippia

Upload your resume to get started.

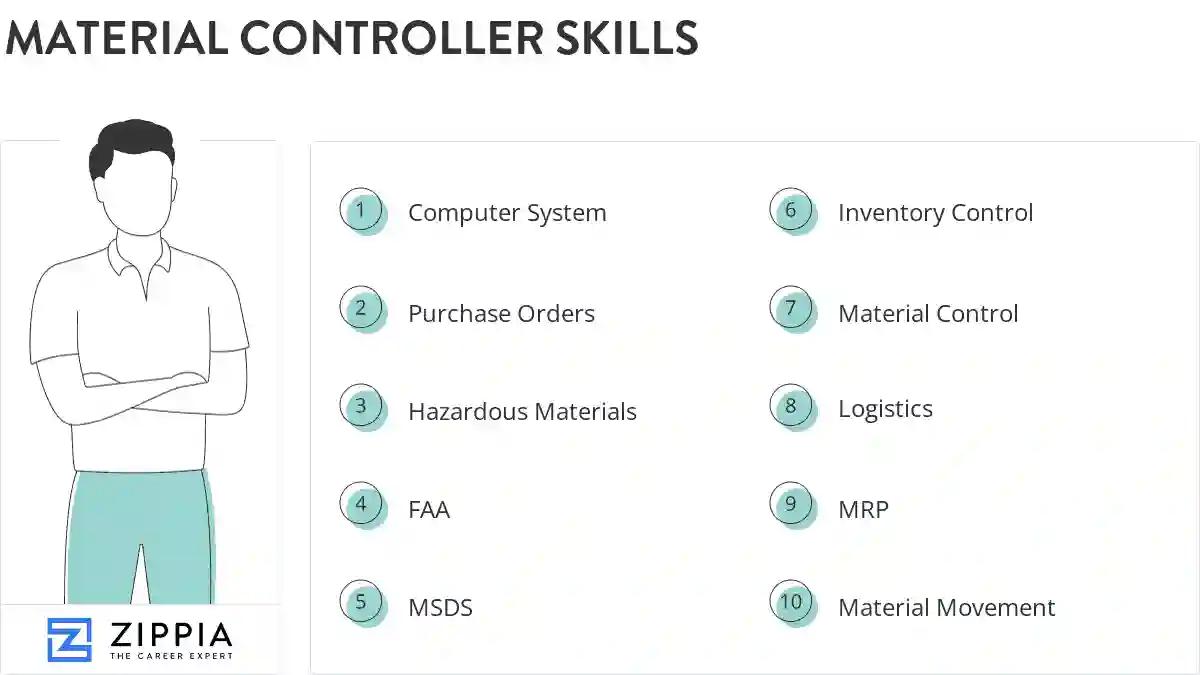

Material controller skills for your resume and career

15 material controller skills for your resume and career

1. Computer System

- Record inventory via computer system to assure accuracy.

- Filled out orders and used UPS computer system to weigh outgoing shipments to determine the price of delivery.

2. Purchase Orders

- Conducted Purchase Order Requisition Maintenance and assisted buyers with questions related to purchase activity in support of aircraft requirements.

- Track purchase orders and verify inventory receipt accuracy.

3. Hazardous Materials

Any substance or good that is harmful to human health as well as the environment are called hazardous materials. Such materials must be handled carefully to avoid any mishaps. Harmful gases. chemicals, strong medicines or drugs, radioactive elements required for radiation purposes, a human blood sample that carries germs, all of these are considered hazardous materials.

- Verify incoming parts for quantities, shortages and damages to include a multiple of hazardous materials also utilizing computers for research.

- Inspect hazardous materials within the assigned work center and coordinates the appropriate office for the disposal of HAZMAT when required.

4. FAA

FAA (Federal Aviation Administration) is an aviation regulatory body in the USA.

- Completed Engineer Order audits monthly to insure compliance with FAA.

- Researched and implemented required service bulletins and airworthiness directives as required by FAA and customer.

5. MSDS

- Completed reports, wrote commodity descriptions, maintains MSDS and other environmental compliance records on materials.

6. Inventory Control

- Developed and implemented computerized inventory control system for permanent equipment shipped from the United States.

- Perform Inventory Control based on confirmed deliveries while escalating unresolved parts issues.

Choose from 10+ customizable material controller resume templates

Build a professional material controller resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your material controller resume.7. Material Control

Material control is the process of monitoring materials during the stages of procurement, storage, and usage to maintain a regular supply of materials.

- Developed inventory management plan and execute for the project material Control.

- Tracked performance data to measure effectiveness of individual material controllers.

8. Logistics

Logistics is a complete organization and implementation of a problem. Logistics are often considered in a complex business operation, as some works need detailed plannings. Logistics are also used in military action.

- Established and implemented policies to standardize project wide logistics and material management processes.

- Managed and coordinated customer delivery commits between production, engineering and logistics.

9. MRP

MRP is an abbreviation of Material Requirements Planning and refers to the control system which is implemented in the planning and management of the activities related to manufacturing. Through MRP, manufacturers can easily schedule the production and it can also be used for inventory. MRP systems are mostly software-based but the process can also be carried out manually.

- Reviewed MRP execution and ensures accuracy of information.

- Manage supplier order books, place orders through MRP, procure gap buys for high risks parts for the Aerospace Industry.

10. Material Movement

- Coordinated Radioactive material movements between ships, and facilities; ensuring smooth transfers and exposure as low as reasonably achievable.

- Implemented the raw material movement system from receipt to production allocation.

11. Production Schedules

The project plan of a film or a documentary that highlights how a production budget will be spent over a given period until its completion is called a production schedule. The scheduling process starts with writing and analyzing the script, which is then broken down to determine and allocate the budget for each scene. The production schedule also includes several elements of the film including; cast actors, special effects, wardrobe, special equipment, stunts, extras, silent bits, production equipment, and many others.

- Coordinate efforts of purchasing and incoming inspection to insure uninterrupted supply of material to meet production schedules.

- Prepare and issue controls production schedules and material requirements to meet production requirements.

12. Safety Regulations

- Initiated safety regulations for all MRT team members.

- Reviewed DoT and OSHA Safety regulations to ensure safety compliances are adhered too.

13. Cycle Counts

Cycle counts are the procedures used in inventory auditing and enable organizations or businesses to count items in various areas within the organization's warehouse without counting the entire inventory.

- Performed periodic physical cycle counts to verify inventory accuracy and identify any shortages.

- Conducted cycle counts on inventory ensuring accuracy in production and warehouse.

14. ERP

Enterprise Resource Planning (ERP) is computer software used by major corporations and organizations for conducting their management and accounting tasks efficiently. ERP systems bind different business processes with each other allowing smoother flow of data between them resulting in swift project assessment and completion.

- Completed SAP ECC ERP systems integration on P2P and OTC by creating and managing Project management plans.

- Utilized SAP Crystal Report software to create reports from complex ERP database.

15. Expedite

- Perform diversified liaison contact between Engineering Planning, and Production Department to expedite parts efficiently per schedule.

- Communicated shortages to Purchasing and coordinated expedites.

5 Material Controller resume examples

Build a professional material controller resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your material controller resume.

What skills help Material Controllers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of material controller skills to add to your resume

The most important skills for a material controller resume and required skills for a material controller to have include:

- Computer System

- Purchase Orders

- Hazardous Materials

- FAA

- MSDS

- Inventory Control

- Material Control

- Logistics

- MRP

- Material Movement

- Production Schedules

- Safety Regulations

- Cycle Counts

- ERP

- Expedite

- Data Entry

- Delivery Schedules

- Inventory Management

- Inventory System

- Production Floor

- Customer Orders

- Material Availability

- Physical Inventory

- Sigma

- ISO

- Part Numbers

- Dollies

- MRO

- Production Control

- Assembly Line

- RMA

- Materials Handling

- RF

- Project Materials

- Production Lines

- Management System

- BOM

- Unload Trucks

- Sales Orders

- Inventory Adjustments

- Maximo

- Windows

- Engineering Changes

- AOG

- PPE

- Sap R

Updated January 8, 2025