Automatically apply for jobs with Zippia

Upload your resume to get started.

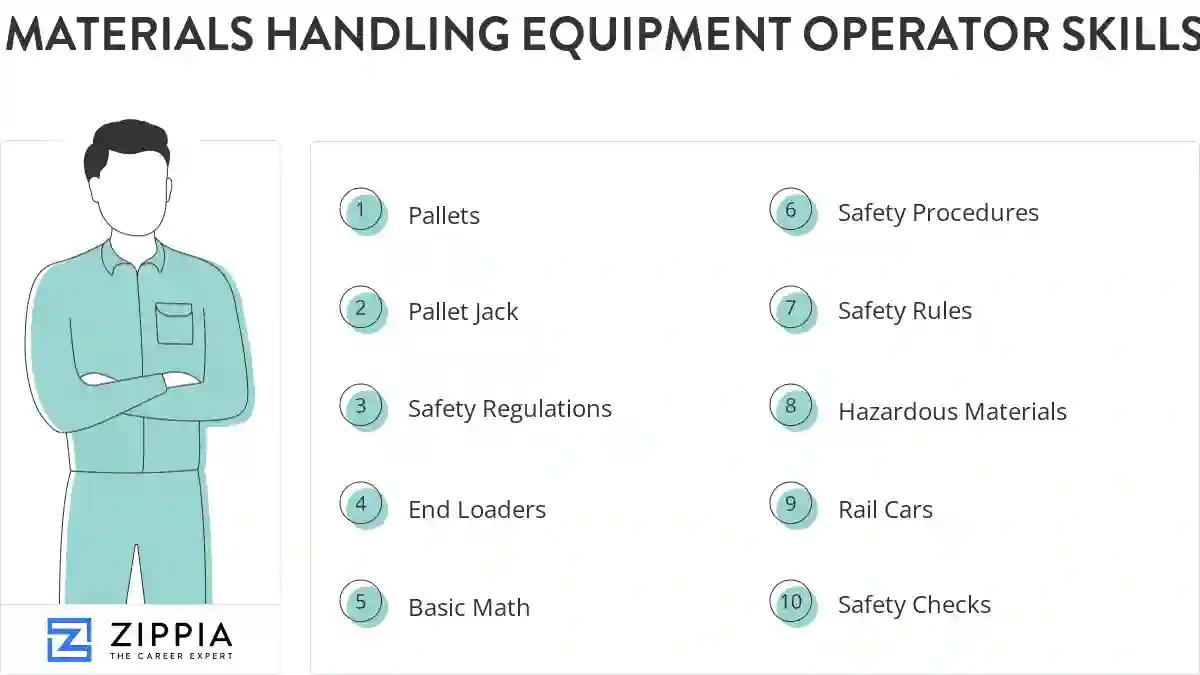

Materials handling equipment operator skills for your resume and career

15 materials handling equipment operator skills for your resume and career

1. Pallets

- Loaded and secured items onto pallets and ensured that the materials were in the proper place and prepared them for shipment.

- Operated forklifts to move heavy pallets and racks to be either loaded or stored in the warehouse.

2. Pallet Jack

- Used various equipment such as selectors, reach trucks, pallet jacks and as well as picked orders by hand.

- Operate power lift truck, work saver, pallet jack and forklifts safely with a 0% incident rate.

3. Safety Regulations

- Completed daily inspections and pre-trip maintenance activities on all equipment in compliance with safety regulations and codes.

- Water Safety Inspection - Performed courtesy inspections of customer equipment and watercraft, making suggestions for requirements to meet safety regulations.

4. End Loaders

- Operated front end loaders, excavators and bulldozers.

- Operated mobile, construction and material equipment including forklifts up to 6000 pounds, backhoes and frontend loaders.

5. Basic Math

- Apply basic mathematical concepts such as adding, subtracting, multiplying, dividing and knowledge of weights and measures.

- Performed basic math skills, lifted dock plates weighing at least 80 pounds, safely handle hazardous materials.

6. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Supervised the use of necessary emergency instruments and ensured proper execution of their mechanical functioning, safety procedures, working condition.

- Can properly operate and function all factory equipment/stations in accordance with general proper factory policy, operations and safety procedures.

Choose from 10+ customizable materials handling equipment operator resume templates

Build a professional materials handling equipment operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your materials handling equipment operator resume.7. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Required to learn company safety rules.

- Read and interpreted work orders *Loaded and unloaded materials *Maintained production sheets *Completed routine records *Followed all safety rules and regulations.

8. Hazardous Materials

Any substance or good that is harmful to human health as well as the environment are called hazardous materials. Such materials must be handled carefully to avoid any mishaps. Harmful gases. chemicals, strong medicines or drugs, radioactive elements required for radiation purposes, a human blood sample that carries germs, all of these are considered hazardous materials.

- Stored, labeled and documented hazardous materials.

- Managed the storage and disposal of hazardous materials and hazardous waste; passed all inspections and maintained a safe work environment.

9. Rail Cars

Rail Cars, also called railroad cars, are large containers set on a railway and pulled by a locomotive. Rail cars are frequently used for shipping large quantities of product or material, such as metal, chemicals, or livestock; however, a rail car may also transport people such as a subway system. A locomotive often pulls numerous cars that attach to each other, which then form a train.

- Use special loading equipment to offload silos with finished product to rail cars and over the road trailers.

- Operate various rail/locomotive equipment to move full/empty rail cars around the plant for offload/loading of product.

10. Safety Checks

Safety checks include all routine maintenance, preventive measures, safety protocols, policies, and regulations performed to ensure a safe working environment. They also include proposals on better management, equipment, installation, and substance disposal methods.

- Conduct daily safety checks on equipment before using.

- Followed all safety requirements and preformed daily safety checks on assigned equipment.

11. Inventory Control

- Help Order Correction department, Inventory Control Department.

- Assist in conducting monthly/annual inventory of supplies/equipment stored at the warehouse; assist inventory control in tagging fixed assets and equipment.

12. Walkie

- Certified on walkie rider, stand-up forklift/ high reach forklift, and turret truck.

- Operated the single and double Walkie and the Standup forklift.

13. RF Scanner

- Received, shipped, issued using RF scanner/computer for warehouse.

- Use of RF scanner to receive and ship orders.

14. PPE

Personal protective equipment is an item of protective clothing such as goggles, helmets, or other garments meant to protect the body from injury.

- Maintain a clean work area and comply with GMP standards including PPE.

- Wear necessary PPE per the requirements of the company.

15. Unload Trucks

Unload trucks is an activity that is undertaken to remove items that have been carried on a truck. It could be raw materials, work-in-stock or finished products. Unloading a truck may require people and some equipment that may help unload items that are too heavy or dangerous for humans to handle.

- Operated forklift to move material, load, and unload trucks.

- Load and unload trucks ensuring shipments are accurate.

5 Materials Handling Equipment Operator resume examples

Build a professional materials handling equipment operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your materials handling equipment operator resume.

What skills help Materials Handling Equipment Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of materials handling equipment operator skills to add to your resume

The most important skills for a materials handling equipment operator resume and required skills for a materials handling equipment operator to have include:

- Pallets

- Pallet Jack

- Safety Regulations

- End Loaders

- Basic Math

- Safety Procedures

- Safety Rules

- Hazardous Materials

- Rail Cars

- Safety Checks

- Inventory Control

- Walkie

- RF Scanner

- PPE

- Unload Trucks

- Hand Trucks

- Equipment Operation

- Warehouse Equipment

- Customer Orders

- Cherry Pickers

- RF Gun

- MHE

- Unload Materials

- Hoists

- Manual Labor

- Computer System

- Equipment Maintenance

- Selector

- Cycle Counts

- Dollies

- Hoisting

- Production Sheets

- Shovels

- Production Lines

- Safety Guidelines

- Bulldozers

Updated January 8, 2025