Automatically apply for jobs with Zippia

Upload your resume to get started.

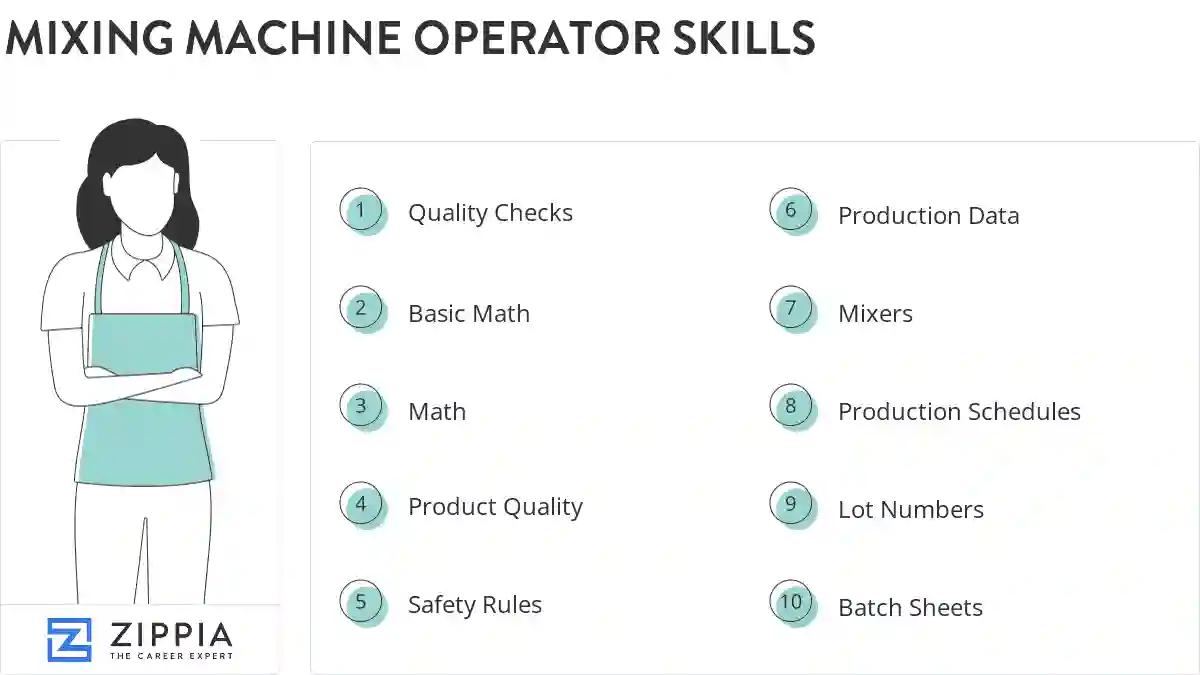

Mixing machine operator skills for your resume and career

15 mixing machine operator skills for your resume and career

1. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Performed quality checks on products and forwarded products to other areas for processing.

- Set equipment parameters for operation Perform quality checks as required.

2. Basic Math

- Followed production instructions and utilized a computer and calculator to aid in basic math calculations.

- Measured dimensions accurately using micrometers, calipers, and basic mathematical skills.

3. Math

- Produced and maintained accurate documentation for production reports using math and computer skills.

- Job required a variety of skills including general math and communication with management.

4. Product Quality

Product quality is the basic element of a business. It means to add features in a product or service in such a way that it meets the needs and wants of the customers. Enhancing the product quality also means improve the goods from any existing defects to ensure customer satisfaction.

- Performed product quality inspections, demonstrating a commitment to continuous improvement, in preparation for air bag distribution and shipping.

- Maintained communication with technicians, supervisors, and operators to ensure product quality and to rectify problems.

5. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Followed safety rules with respect to nitrogen purging systems and ground clamps.

- Utilize safety practices and procedures following established safety rules and regulations and maintains a safe and clean environment.

6. Production Data

Production data is the data stored and used by business owners to conduct business. Production data must be accurate, well documented, and readily available as it is essential to completing day-to-day business tasks and processes.

- Record and enter production data.

- Followed safety guidelines and procedures, performed accurate recording of production data, maximized efficiency and called for maintenance.

Choose from 10+ customizable mixing machine operator resume templates

Build a professional mixing machine operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your mixing machine operator resume.7. Mixers

- Helped my coworkers meet their quotas and trained new employees to be mixers.

- Operate viscometer, solids testers, bulk metering systems, and various high speed mixers.

8. Production Schedules

The project plan of a film or a documentary that highlights how a production budget will be spent over a given period until its completion is called a production schedule. The scheduling process starts with writing and analyzing the script, which is then broken down to determine and allocate the budget for each scene. The production schedule also includes several elements of the film including; cast actors, special effects, wardrobe, special equipment, stunts, extras, silent bits, production equipment, and many others.

- Reviewed the production schedule to insure the correct product to be produced.

- Check production schedules daily to stage packaging and ingredients if needed.

9. Lot Numbers

- Keep track of lot numbers for each ingredient to ensure consistent quality control.

- Documented ingredient lot numbers, batch times, batter temps, etc.

10. Batch Sheets

- Processed dry and liquid chemicals by following batch sheet for mixing ingredients.

- Follow batch sheets and follow all procedures of mixing products

11. GMP

GMP stands for Good Manufacturing Practice. It is a system that ensures that all products like food, beverages, and medicinal drugs that are produced comply with the quality standards. It helps in minimizing the risks and hazards that cannot be eliminated after the testing of final products.

- Maintained a high level of sanitation and GMP's throughout the mixing department.

- Adhere to safety and GMP (Good Manufacturing practice) guidelines

12. HACCP

- Managed production and sanitation teams ensuring the production of safe food products under the company s Sanitation regulations and HACCP guidelines.

- Manufacture products to ensure that they meet specifications, and HACCP requirements.

13. Blend Ingredients

- Dumped ingredients into mixing machines and started machines to blend ingredients.

- Operated machines that mix or blend ingredients for specified times.

14. Machine Operation

- Instructed on machine operations and safety operations.

- Set thermostat to regulate temperature and observed machine operation and examined products ejected by machines to determine whether products meet specifications.

15. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Ensured quality of product and that machine ran smoothly, used banding and packaging equipment.

- Dumped 50lbs bags of ingredients into blenders then ran the line bagging and sealing the finished product and palletized

5 Mixing Machine Operator resume examples

Build a professional mixing machine operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your mixing machine operator resume.

What skills help Mixing Machine Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of mixing machine operator skills to add to your resume

The most important skills for a mixing machine operator resume and required skills for a mixing machine operator to have include:

- Quality Checks

- Basic Math

- Math

- Product Quality

- Safety Rules

- Production Data

- Mixers

- Production Schedules

- Lot Numbers

- Batch Sheets

- GMP

- HACCP

- Blend Ingredients

- Machine Operation

- RAN

- Measure Materials

- Production Specifications

- Assembly Line

- Production Process

- Production Lines

- Troubleshoot

- Bakery Products

- Quality Standards

- Safety Procedures

- Test Results

- Clean Machines

- Measure Ingredients

- Computer System

- Test Equipment

- Extruders

- Mix Ingredients

- Test Data

- CIP

- Storage Tanks

Updated January 8, 2025