Automatically apply for jobs with Zippia

Upload your resume to get started.

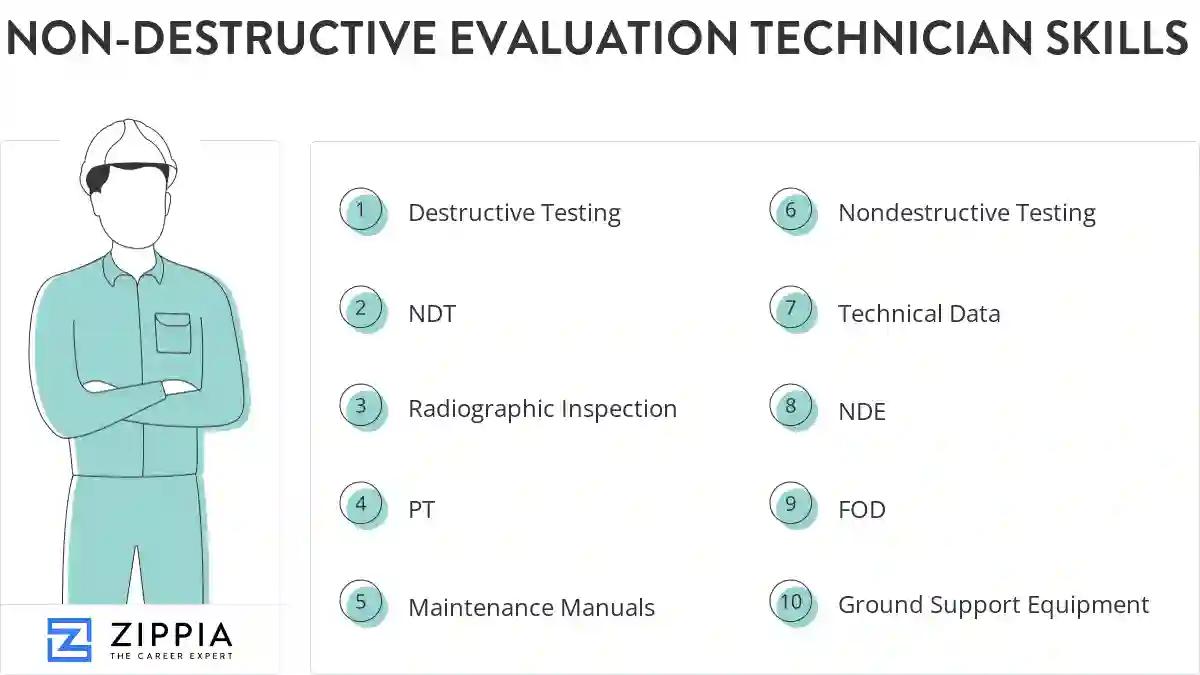

Non-destructive evaluation technician skills for your resume and career

12 non-destructive evaluation technician skills for your resume and career

1. Destructive Testing

- Develop or use new non-destructive testing methods such as acoustic emission testing, leak testing, and thermal or infrared testing.

- Selected, calibrated, and operated equipment used in the non-destructive testing (NDT) of military aircraft and aviation components.

2. NDT

Non-Destructive Testing, NDT, is a combination of different test techniques used individually or collectively to evaluate the integrity and properties of a material, component, system, or structure without permanently altering it. NDT is important for safe operation, as well as for quality control and lifetime evaluation of the system. It is used in industries such as aerospace, oil, and gas, nuclear, power generation, medical, rail, general manufacturing, etc.

- Developed and implemented NDT methods using all aforementioned disciplines.

- Determined the serviceability of aircraft components and structures by means of several disciplines of Non-Destructive Testing (NDT).

3. Radiographic Inspection

- Performed radiographic inspections on various materials using Conventional and Digital Radiography.

4. PT

PT which stands for Prothrombin Time is a test to evaluate the body's ability to properly form blood clots using one's blood sample. PT results are used to calculate the International Normalized Ratio (INR) which detects the effectiveness of blood-thinning medications like Warfarin taken by patients that have blood-clotting disorders.

- Performed over 150 hours in ET and PT, and over 50 hours in UT and MT.

- Experience with: Digital video cameras, Computers, Power drills, Olympus-brand Ultrasonic inspection equipment, PT and MT procedures.

5. Maintenance Manuals

- Tested electrical components utilizing test fixtures as instructed by manufacturer's component maintenance manuals.

- Bore Scopes), Technical Quality Maintenance Manuals and Engineering Specifications prescribed by G.E and Pratt & Whitney.

6. Nondestructive Testing

- Set up and calibrated nondestructive testing equipment.

Choose from 10+ customizable non-destructive evaluation technician resume templates

Build a professional non-destructive evaluation technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your non-destructive evaluation technician resume.7. Technical Data

Technical data refers to both scientific and technical nature and information recorded and presented in any form other than financial and management information but includes manuals and instructional materials, as well as technical data formatted as a computer database.

- Disassemble and assemble engines and propellers adhering to prescribed procedures in technical data.

- Initiated Technical data change to F119 trailer servicing hazard, saved 109 F22 trailer fleet.

8. NDE

Nondestructive evaluation (NDE) is a term used in describing quantitative measurements and locating a defect. It helps identify material properties like formability and fracture toughness. Majority of people know the technology used in NDE from the medical industries such as x-ray and ultrasound.

- Performed NDE inspections at nuclear, chemical, oil/petrochemical plants and various manufacturing facilities.

- Perform as Lead NDE Technician on Capital Projects for various contractors.

9. FOD

FOD is the safety and quality control process followed in environments where loose objects, wildlife and small debris make cause damage to equipment, employees, visitors, or passengers. In worse cases, it will also lead to production delays and violation of safety regulations.

- Maintained tool control, ingress and egress of equipment and personnel into controlled work areas and exercise FOD prevention.

- Used tool control and tool tracking with zero tolerance for FOD.

10. Ground Support Equipment

Ground support equipment provides passenger and baggage handling, aircraft handling, and docking at an airport.

- Performed corrective and preventive maintenance on ground support equipment.

- Managed calibration and inventory schedules for ground support equipment.

11. Oil Analysis

- Performed spectrometric oil analysis and evaluated engine oil break down and trends.

- Performed oil analysis on all aircraft after each air show demonstrations.

12. Process Control

Process control is a method pertaining to continuous production processes that uses the aid of ICS (Industrial Control Systems) for production. This method enables production to be done with a level of consistency and safety in an economically friendly manner that is impossible to achieve solely through manual control.

- Performed process control on laboratory equipment to maintain reliability and prevent misinformation.

- Performed & analyzed process control automated management checks to ensure 100% integrity of all NDI media.

What skills help Non-Destructive Evaluation Technicians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of non-destructive evaluation technician skills to add to your resume

The most important skills for a non-destructive evaluation technician resume and required skills for a non-destructive evaluation technician to have include:

- Destructive Testing

- NDT

- Radiographic Inspection

- PT

- Maintenance Manuals

- Nondestructive Testing

- Technical Data

- NDE

- FOD

- Ground Support Equipment

- Oil Analysis

- Process Control

Updated January 8, 2025