Automatically apply for jobs with Zippia

Upload your resume to get started.

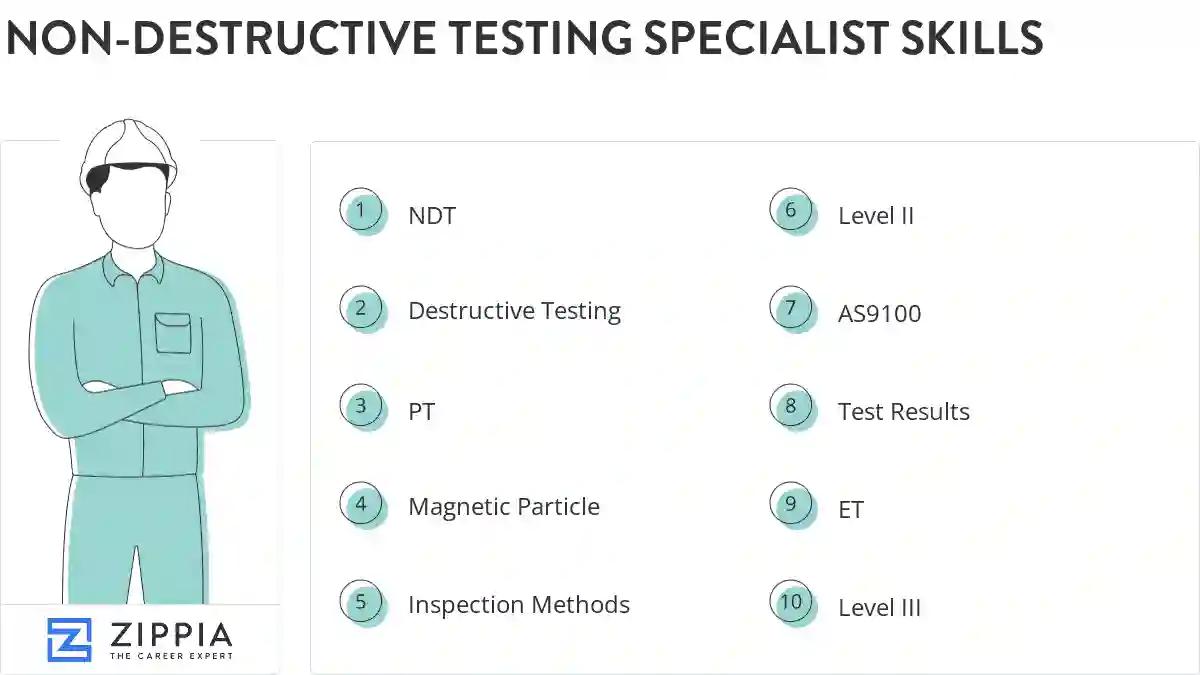

Non-destructive testing specialist skills for your resume and career

15 non-destructive testing specialist skills for your resume and career

1. NDT

Non-Destructive Testing, NDT, is a combination of different test techniques used individually or collectively to evaluate the integrity and properties of a material, component, system, or structure without permanently altering it. NDT is important for safe operation, as well as for quality control and lifetime evaluation of the system. It is used in industries such as aerospace, oil, and gas, nuclear, power generation, medical, rail, general manufacturing, etc.

- Selected, calibrated, and operated equipment used in the non-destructive testing (NDT) of products or materials.

- Examined vehicles, aircraft, and aerospace ground equipment using non-destructive testing (NDT) techniques.

2. Destructive Testing

- Meet Level-2 qualifications, MIL-STD-410, Nondestructive Testing Personnel Qualification and Certification.

- Inspected aerospace weapons systems components and support equipment for structural integrity using nondestructive testing methods.

3. PT

PT which stands for Prothrombin Time is a test to evaluate the body's ability to properly form blood clots using one's blood sample. PT results are used to calculate the International Normalized Ratio (INR) which detects the effectiveness of blood-thinning medications like Warfarin taken by patients that have blood-clotting disorders.

- Experience with: Digital video cameras, Computers, Power drills, Olympus-brand Ultrasonic inspection equipment, PT and MT procedures.

- Performed PT, MT, VT and RT methods on refurbished turbine engine components to customer specifications.

4. Magnetic Particle

Magnetic Particle testing, also known as Magnetic Particle Inspection, is a method or examination used to determine the flaws of the surface and subsurface materials like nickel, iron, cobalt, and alloy.

- Level III certified in Fluorescent Penetrant, Magnetic Particle, Eddy Current, and Ultrasonic.

- Certified Level II to SNT-TC-IA in radiography, magnetic particle and liquid penetrant inspections.

5. Inspection Methods

- Perform inspection methods and daily tasks in accordance with company specific controlled instructions.

- Used X-ray and isotope inspection methods to verify engine component integrity.

6. Level II

Level II often marks a grade of experience one gains in the workplace. Depending on the field, a Level II certification may require a certain class or number of years of on-site work and training. For instance, in a medical or therapeutic field, a Level II designation is applied to individuals that achieve professionalism in their career, who demonstrate a higher level of clinical reasoning, and that help a certain number of clients.

- Certified Inspector Level II Liquid Penetrant Inspection.

- Worked as a Level II Radiographer; X-Ray pipeline and various pipeline facilities in accordance with various code and safety guidelines.

Choose from 10+ customizable non-destructive testing specialist resume templates

Build a professional non-destructive testing specialist resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your non-destructive testing specialist resume.7. AS9100

- Ensured adherence and compliance to company and industry policies & procedures such as Nadcap and AS9100.

8. Test Results

- Evaluated test results against designated standards utilizing knowledge of metals and testing experience.

- Interpreted and evaluated test results and maintained equipment.

9. ET

- Eddy Current Testing (ET), Radiography Testing(RT); film and digital.

- Performed tube and digital x-ray, automated ET and UT on welds in manufactured steel subsea tubing.

10. Level III

- Work with responsible Level III to establish FPI, MPI technique sheets for operations.

- Review all questionable indications with responsible Level III inspector.

11. Ultrasonic Testing

- Identify defects in solid materials using ultrasonic testing techniques.

- Automated immersion Ultrasonic testing of titanium

12. API

- Code proficiency in ASME, ASTM, API, AAR, & MIL-STD.

13. Ultrasound

Ultrasound refers to an imaging method that uses high-frequency sound waves to produce images of structures within your body.

- Performed general metals and weld strength testing using Radiography and Ultrasound Technology.

- Performed inspection using x-ray, ultrasound, fluorescent, oil analysis and magnetic techniques.

14. Radiographic Images

- Make radiographic images to detect flaws in objects while leaving objects intact.

15. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Identified defects and generated reworks to improve quality standards to approximately 50%.

- Assured Quality Standards were met and adhered to.

5 Non-Destructive Testing Specialist resume examples

Build a professional non-destructive testing specialist resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your non-destructive testing specialist resume.

What skills help Non-Destructive Testing Specialists find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of non-destructive testing specialist skills to add to your resume

The most important skills for a non-destructive testing specialist resume and required skills for a non-destructive testing specialist to have include:

- NDT

- Destructive Testing

- PT

- Magnetic Particle

- Inspection Methods

- Level II

- AS9100

- Test Results

- ET

- Level III

- Ultrasonic Testing

- API

- Ultrasound

- Radiographic Images

- Quality Standards

- Oil Analysis

Updated January 8, 2025