Automatically apply for jobs with Zippia

Upload your resume to get started.

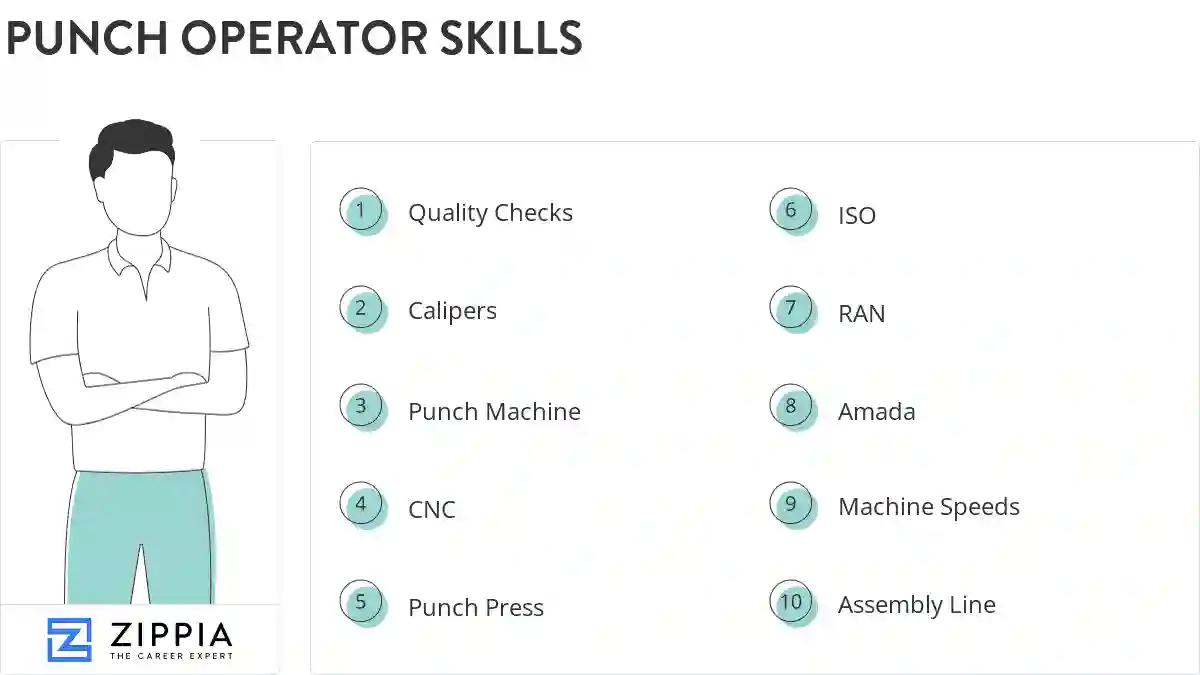

Punch operator skills for your resume and career

15 punch operator skills for your resume and career

1. Quality Checks

Quality checks are a component of quality control aimed at ensuring that quality requirements are met. Internally, quality checks provide assurance to managers, and externally, it provides assurance to clients, federal departments, authorities, and certifiers.

- Maintained mandatory scheduling for quality checks, leading to product and process improvements over time.

- Perform quality checks using the proper measuring devices correctly during operation and complete quality records.

2. Calipers

- Inspected final product using micrometer and calipers per Specialized Product Control to ensure out-of-specification parts were identified.

- Calculate dimensions and tolerances using knowledge of mathematics and instruments such as micrometers and vernier calipers.

3. Punch Machine

- Load steel on Laser/punch machine, manipulate program for proper part size or order.

- Performed and operated maintenance of power punch machinery on a daily basis.

4. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Operated, setup and programmed (CNC) hydraulic press that stamped steel parts for seat rails.

- Operate CNC HURCO AMADA M-20, CNC Ban Saw machine Lathe, Drill Press & Grinders.

5. Punch Press

- Set up and operate punch presses, including coil-feed, progressive and automatic.

- Operated turret punch press to punch holes or layout Mars in metal sheets, plates,strips or bars.

6. ISO

- Conform to ISO 9001:2008, ISO / TS16949 Third Edition and ISO 14001 automotive quality and environmental standards.

- Uphold all ISO and OSHA standards applicable to the responsibilities listed above.

Choose from 10+ customizable punch operator resume templates

Build a professional punch operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your punch operator resume.7. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Maintained tools, including preventive maintenance, to make sure the tool ran correctly.

- Tow Motor Driver * Ran plastic blow-mold press * Relieved operators for break and trained new operators.

8. Amada

- Put sheet metal onto Amada machine Set up, operator, machine to cut metal Start machine and monitor operation

- Program setup, tool and die maintenance for AMADA 358 turret press.

9. Machine Speeds

- Tested and adjusted machine speeds and actions according to project specifications.

- Test and adjust machine speeds or actions, according to product specifications, using gauges and hand tools.

10. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Delivered quality parts to the assembly line- helped increase the production to waste ratio by 20%.

- Operated semi-automatic assembly line used to assemble and package the bearing according to customer orders.

11. Machine Operation

- Build and install own tooling for machine operation.

- Monitor machine operation and control panel displays and compare readings to specifications to detect malfunctions.

12. Press Brake

- Keep punches and dies sharp and operate press brakes and power presses

- Shear parts for press brakes and Pega machine.

13. Laser Cutting

- Perform all duties associated with the operation of Mitsubishi Lasers for precision laser cutting and fabrication to include troubleshooting as necessary.

- Performed laser cutting and welding operations by imputing proper cutting welding program with appropriate material.

14. Punch Holes

- Read blue print for specific lay-out of parts Used machine to bend parts and punch holes

- Operated equipment to punch holes and to gauge pieces and ensure 100% quality

15. MIG

MIG is a specific type of welding in which two base materials are welded together using a solid wire electrode fed through a welding gun and into the weld pool.

- Welded with MIG welders, automatic guided, and free handed.

- Used tooling consisted of Oxygen/acetylene torches, grinders, welding equipment including MIG and flux-core wire using noble gas shields.

5 Punch Operator resume examples

Build a professional punch operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your punch operator resume.

What skills help Punch Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of punch operator skills to add to your resume

The most important skills for a punch operator resume and required skills for a punch operator to have include:

- Quality Checks

- Calipers

- Punch Machine

- CNC

- Punch Press

- ISO

- RAN

- Amada

- Machine Speeds

- Assembly Line

- Machine Operation

- Press Brake

- Laser Cutting

- Punch Holes

- MIG

Updated January 8, 2025