Automatically apply for jobs with Zippia

Upload your resume to get started.

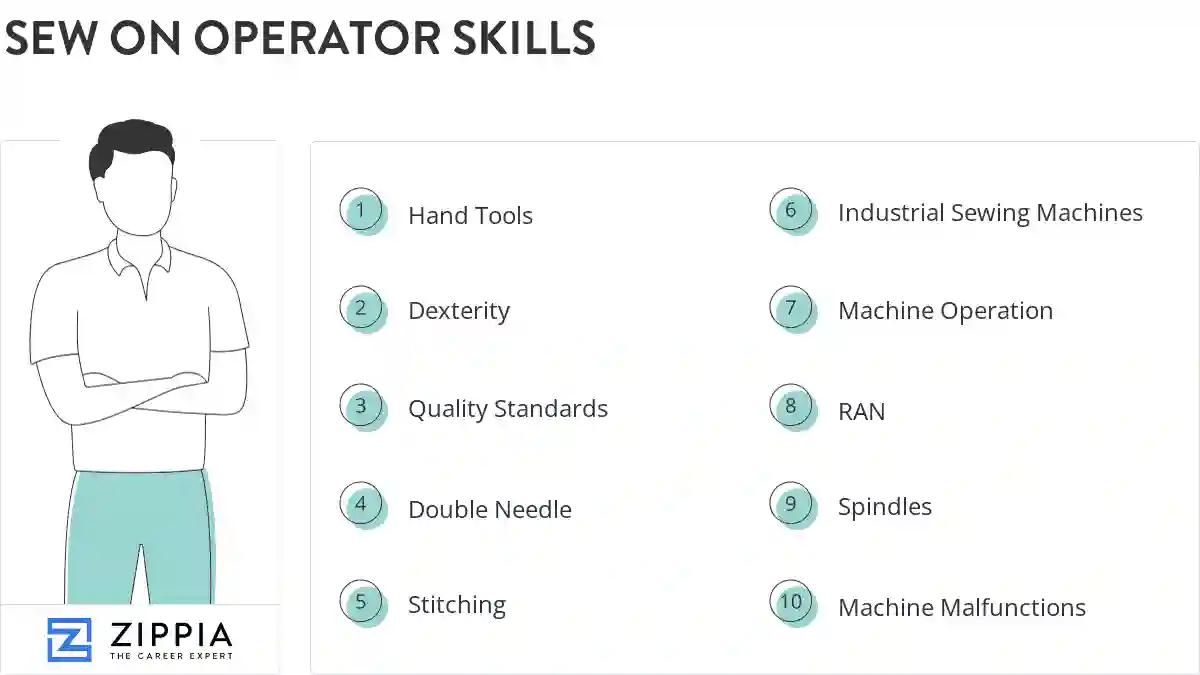

Sew on operator skills for your resume and career

15 sew on operator skills for your resume and career

1. Hand Tools

- Work with small hand tools using dexterity and accuracy to sew leaflet, which is tissue from a cow.

2. Dexterity

- Have very good hand and finger dexterity while working on piece work to sew sweat shirts, pants, and etc.

3. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Preserved a safe and clean work environment by following the company's safety and quality standards.

- Planned daily output of production on timely basis Applied quality standards

4. Double Needle

- Operated single and double needle machine.

- Operated various sewing machines, including single needle serging, double needle serging and flat-bed felling machines.

5. Stitching

- Monitored sewing machine operations and observed defects in stitching or machine malfunctions.

- Observed sewing machine operation to detect defects in stitching and machine malfunction and notified supervisor.

6. Industrial Sewing Machines

- Sewed medical braces according to strict quality standards-Trimmed and packaged completed products-Assisted mechanic in tuning and repairing industrial sewing machines

- Repaired and tailored customers' canvas and accessory items using industrial sewing machines.

Choose from 10+ customizable sew on operator resume templates

Build a professional sew on operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your sew on operator resume.7. Machine Operation

- Monitor machine operation to detect problems or machine malfunctions.

- Operated sewing machines, Monitored machine operation.

8. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Changed needles, thread, and replaced elastic on machines if it broke or ran out.

- collated jobs, set up and ran 3-hole drill.FOLDER OPERATOR, ACCURATE BUSINESS MAILER

9. Spindles

- Placed spools of thread on spindles, inserted bobbins, and threaded ends through machine guides and components.

- Place spools of thread on spindles, ensure machine is threaded properly.

10. Machine Malfunctions

- Notified sewing machine mechanic when defects were caused by machine malfunctions.

- Noted and reported all machine malfunctions to management.

11. Parachutes

- Sew Parachutes I operated sewing machine to join parts of fabricated textile products.

- Sew Parachutes I packaged parts.

12. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Operated industrial sewing machine on assembly line production.

- Sewed military uniforms on a production assembly line.

13. Pump Stations

Pump stations fulfill the job of transferring liquids from one place to another. These operate on a small scale for the increase in water pressure at homes or restaurants -- similarly, it works on a larger scale at petrol stations or supplies water in canals. With the volume and amount of the liquid set as a subject, the pump station's size corresponds with its cost. The ideal pump station is efficient and less costly with the proper and safe transfer of liquid.

- Operate and maintain backup wells, reservoirs, pump stations and elevated tanks.

- Perform the installation, maintenance and repair of the physical plant and pump stations and all of their components.

14. Machine Guides

- Mount attachments, such as needles, cutting blades, or pattern plates, and adjust machine guides according to specifications.

- Mounted attachments, such as needles, cutting blades, or pattern plates, and adjust machine guides according to specifications.

5 Sew On Operator resume examples

Build a professional sew on operator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your sew on operator resume.

What skills help Sew On Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of sew on operator skills to add to your resume

The most important skills for a sew on operator resume and required skills for a sew on operator to have include:

- Hand Tools

- Dexterity

- Quality Standards

- Double Needle

- Stitching

- Industrial Sewing Machines

- Machine Operation

- RAN

- Spindles

- Machine Malfunctions

- Parachutes

- Assembly Line

- Pump Stations

- Machine Guides

- Repair Tags

- Machine Functions

- Oiling

- Customer Specifications

- Presser Feet

- Cushions

- Equipment Maintenance

- Thread Ends

- Coats

- Toyota

- Cutting Blades

- Equipment Performance

- Safety Regulations

- Water Meters

- Water Lines

- Position Material

Updated January 8, 2025