Automatically apply for jobs with Zippia

Upload your resume to get started.

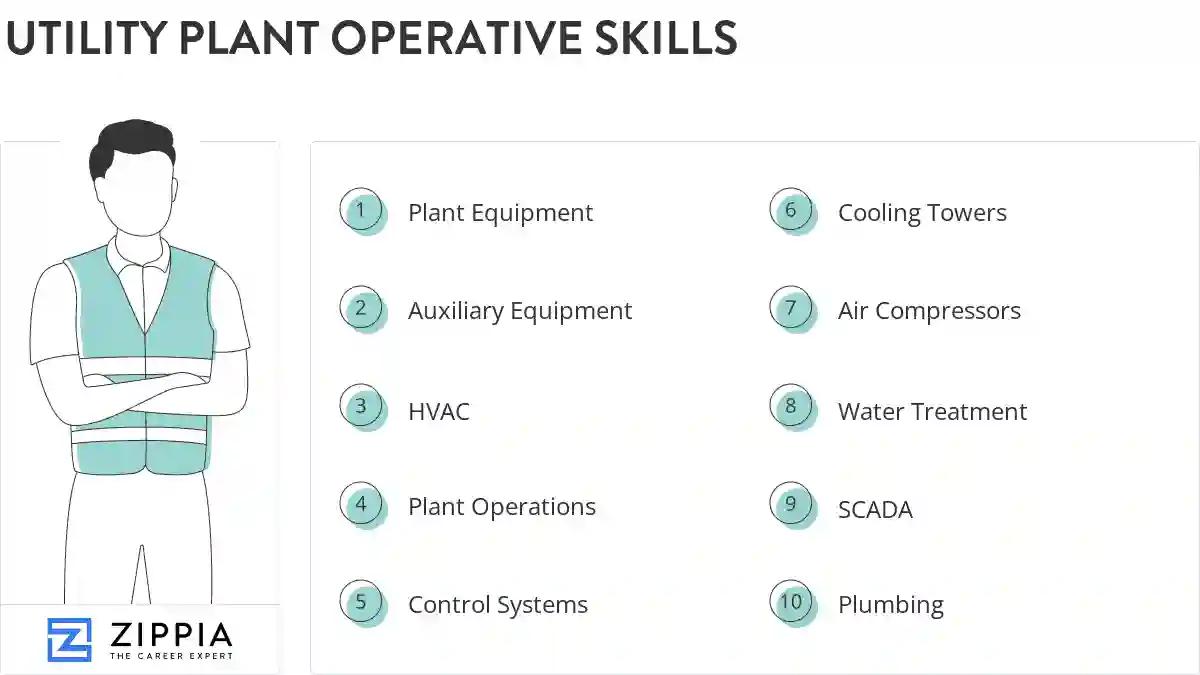

Utility plant operative skills for your resume and career

15 utility plant operative skills for your resume and career

1. Plant Equipment

The equipment that has a capital nature and can be easily moved from personal property is called plant equipment. Unlike fixed equipment, plant equipment is temporarily added to the structure of a building. These can be appliances, power tools, forklifts, vehicles, etc. Plant equipment plays a vital role in plant maintenance and ensures that the area has minimum breakdowns and the plant is fully functional at the lowest possible cost

- Demonstrate procedural compliance in all plant operation activities of plant equipment through established valve line-ups and system/component operation procedures.

- Completed Scheduled Preventative Maintenance on all Plant equipment.

2. Auxiliary Equipment

Auxiliary Equipment will differ depending on the work environment, but it is often recognized as machinery that promotes efficiency within a company. Auxiliary equipment can complete work without employee input or direct communication. This equipment can range from something as simple as conveyor belts and bulk storage to more complex machines that assist with oil extraction.

- Operate & maintain two 250hp & one 350hp fire tube boilers, also two 550hp centrifugal chillers, with auxiliary equipment.

- Operated boilers, chillers, steam turbines, cooling towers and auxiliary equipment in a central heating and cooling plant.

3. HVAC

- Performed preventive maintenance on multiple systems such as HVAC, Hydraulics, Fire Protection, Water Treatment and Pneumatic.

- Established reliable efficient and continuously improving Facilities, Utilities and HVAC operations.

4. Plant Operations

- Observe and control plant operations through 3 building automation systems, which include 2 Siemens and 1 Honeywell.

- Work with Global Energy Group to provide feedback on energy consumption impacts of plant operations.

5. Control Systems

- Monitored and tracked control systems and equipment, such as emissions and run status, using a DCS Bailey computer system.

- Field instrumentation, process analyzers, process control systems and/or electrical power distribution equipment.

6. Cooling Towers

- Preform all water tests and add chemicals for boilers, cooling towers, condensate returns and softeners.

- Maintained water chemistry on all cooling towers on Auburn site by performing testing, calibration and repair of chemical systems.

Choose from 10+ customizable utility plant operative resume templates

Build a professional utility plant operative resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your utility plant operative resume.7. Air Compressors

An air compressor is a power tool used to convert power into potential energy, which is generally stored in the form of compressed air. Air compressors have several methods of pushing more air into a cylinder, thereby increasing the pressure. The compressor stops when the pressure reaches its upper limit and remains in the tank until demand occurs.

- Operate Air Compressors, air dryers, and associated equipment, Ingersoll-Rand and Quincy maintain plant air and operating air pressures.

- Maintained the Operation and Maintenance on (5) Kaesor air compressors with air- dryers to maintain set dew point.

8. Water Treatment

- Interpret monitored results to make adjustments to chemical processes in the town's 5 MGD water treatment plant.

- Manage utility plant maintenance contracts (chiller, water treatment, gas turbine, etc.)

9. SCADA

- Operated Wolf Creek Hydro Electric Power Plant and Dam locally and operated Laurel Power Plant and Dam via SCADA remote control.

- Operate computer System Control and Data Acquisition (SCADA) to control and monitor plant flow.

10. Plumbing

- Performed some plumbing repairs, minor electrical work, some carpentry, plus general maintenance at plant and offices.

- Plant maintenance including light plumbing and light electrical work, Custom fabrication.

11. Plant Maintenance

Plant maintenance includes all preventive measures, processes, and operations concerned with plant life.

- Plant maintenance and chemical treatment of boiler feed water.

- Work cooperatively with Process Engineer to facilitate and provide ongoing plant maintenance and improvements.

12. Hot Water

- Maintain and operate low pressure boilers for heat and hot water service- Performed a preventative maintenance schedule on all auxiliary equipment

- Overhauled boilers and heating/hot water equipment.

13. Maintenance Procedures

A maintenance procedure refers to a thorough list of steps that details the way a maintenance task needs to be performed. It also acts as a documented standard that should be maintained when performing the task or job.

- Developed lock-out/tag-out and maintenance procedures to support initial plant construction and start-up, and the construction and tie-in of additional production lines

- Record data for maintenance procedures and schedules.

14. Control Room

A control room, also known as an operations center, is a room that serves as central control and monitoring station for security, building, and other types of systems of a large facility or physical area. Control rooms act as the central nervous system of a facility and require a reliable and efficient communication system to effectively handle emergencies, as well as critical incidents and decisions.

- Oversee the operation of the control room and direct the work of the Auxiliary Operators.

- Performed duties as maintenance technician and control room operator in a boiler/chiller plant.

15. Water Samples

- Collected water samples and ran lab tests to make sure the water was drinkable.

- Take water samples and run various test such as calcium, hardness ext.

5 Utility Plant Operative resume examples

Build a professional utility plant operative resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your utility plant operative resume.

What skills help Utility Plant Operatives find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of utility plant operative skills to add to your resume

The most important skills for a utility plant operative resume and required skills for a utility plant operative to have include:

- Plant Equipment

- Auxiliary Equipment

- HVAC

- Plant Operations

- Control Systems

- Cooling Towers

- Air Compressors

- Water Treatment

- SCADA

- Plumbing

- Plant Maintenance

- Hot Water

- Maintenance Procedures

- Control Room

- Water Samples

- Water Systems

- Treatment Plant

- GMP

- Fuel Oil

- EPA

- Minor Maintenance

- FDA

- Production Equipment

- Equipment Operation

- Ventilation

- Chemical Analysis

- Hazardous Chemicals

- Air Systems

- Routine Maintenance

- PLC

- Water Plants

- Lab Tests

- Federal Regulations

- PPE

- Lockout

- Dryers

- Potable Water

- End Loaders

- Production Facilities

- Support Equipment

- Building Automation Systems

Updated January 8, 2025