What does a batch maker do?

Batch maker responsibilities

Here are examples of responsibilities from real batch maker resumes:

- Operate numerous types of CIP systems.

- Recognize and used PPE need to perform daily job functions.

- Operate CIP process equipment in accordance with quality system procedures.

- Partner with QA to maintain the product spec's and ensure food quality.

- Maintain the accuracy of batch logs and keep up-to-date detail production records to comply with GMP.

- Follow strict GMP rules and guidelines in properly sanitizing and maintaining all equipment used in making the products.

- Maintain sterilization of equipment and prep areas for cleanliness.

- Ensure efficient maintenance of assign rig equipment.

Batch maker skills and personality traits

We calculated that 13% of Batch Makers are proficient in Basic Math, Safety Procedures, and Math. They’re also known for soft skills such as Detail oriented, Physical strength, and Math skills.

We break down the percentage of Batch Makers that have these skills listed on their resume here:

- Basic Math, 13%

Perform basic mathematical calculations as needed to ensure product quantities are accurately packaged.

- Safety Procedures, 9%

Conduct employee training in equipment operations or work and safety procedures, or assign duties to experienced workers.

- Math, 8%

Used math to calculate formulas, made bulk cow/chicken feed with communication skills, used computer operations to mix feed

- GMP, 7%

Followed companies safety rules and used appropriate PPE and safety gear provided Follows GMP policies and HACCP.

- Quality Checks, 6%

Manufacture intermediates, take samples to lab to be quality checked and perform other tasks as necessary.

- Batch Ticket, 5%

Review batch ticket and add specified amounts of raw materials into mixer/spray dry or blending tanks.

Common skills that a batch maker uses to do their job include "basic math," "safety procedures," and "math." You can find details on the most important batch maker responsibilities below.

Detail oriented. The most essential soft skill for a batch maker to carry out their responsibilities is detail oriented. This skill is important for the role because "workers must be able to detect small changes in the quality or quantity of food products." Additionally, a batch maker resume shows how their duties depend on detail oriented: "maintained the accuracy of batch logs and kept up-to-date detailed production records to comply with gmp. "

Physical strength. Many batch maker duties rely on physical strength. "food processing equipment workers must be able to lift or move heavy boxes of ingredients, which may weigh up to 50 pounds.," so a batch maker will need this skill often in their role. This resume example is just one of many ways batch maker responsibilities rely on physical strength: "produced batches by precisely entering or physically loading, formula ingredients per batch ticket via pod system or scale weigh-in. "

Math skills. This is an important skill for batch makers to perform their duties. For an example of how batch maker responsibilities depend on this skill, consider that "workers may need math skills in order to accurately mix specific quantities of ingredients." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a batch maker: "used math abilities to follow batch ticket formulas to produce container coatings in mixing environment. ".

The three companies that hire the most batch makers are:

- PPG7 batch makers jobs

- ITW6 batch makers jobs

- Alere

3 batch makers jobs

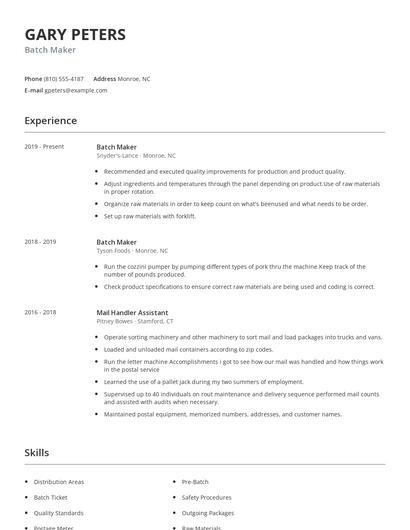

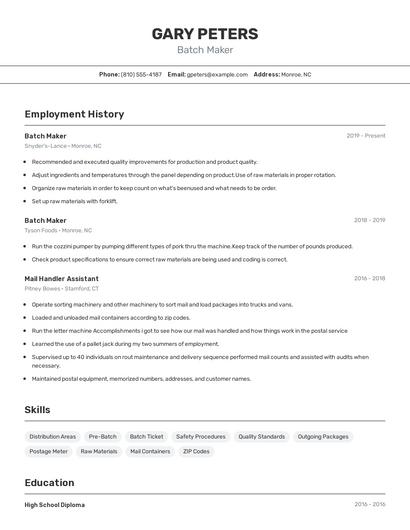

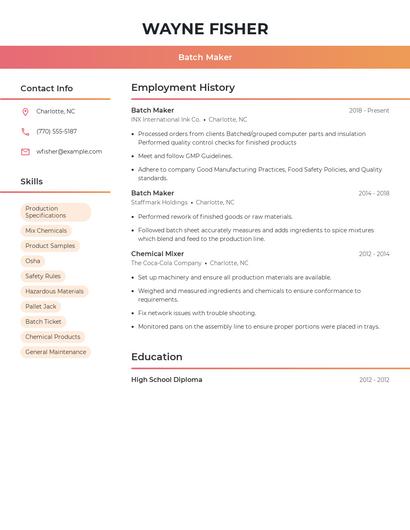

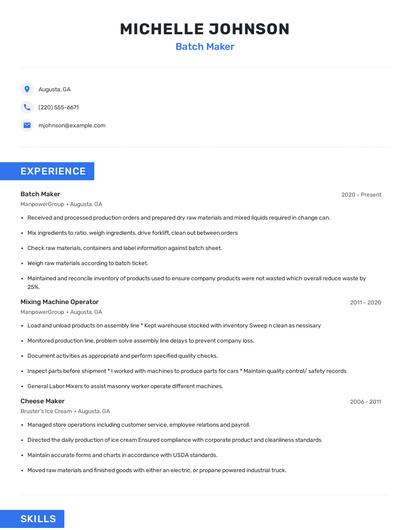

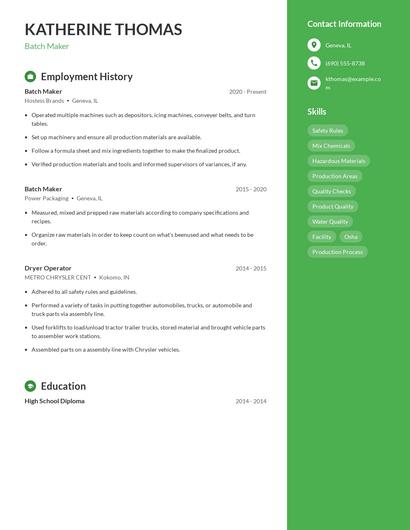

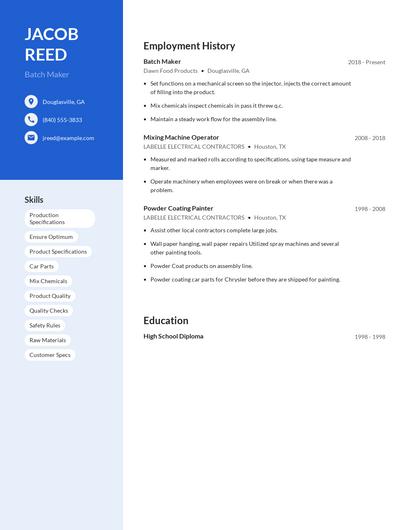

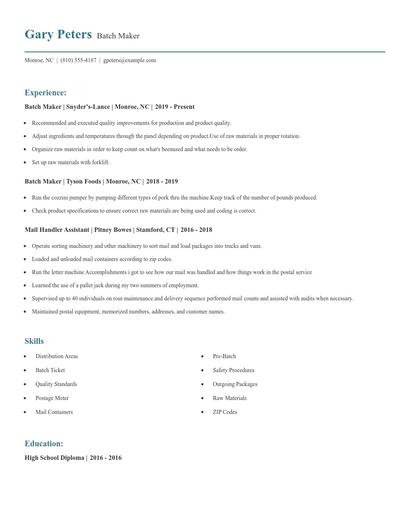

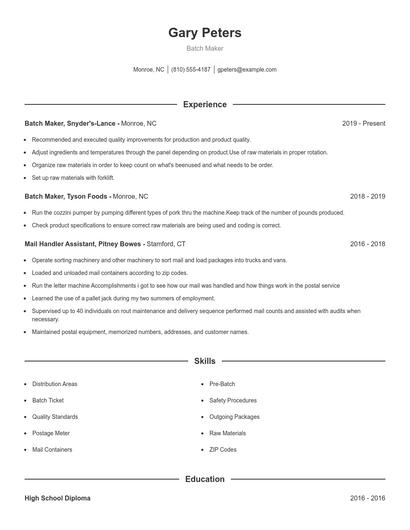

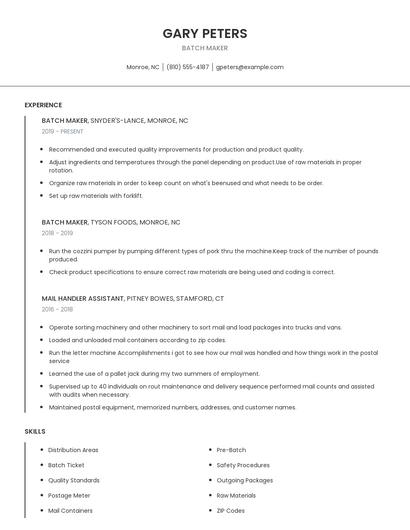

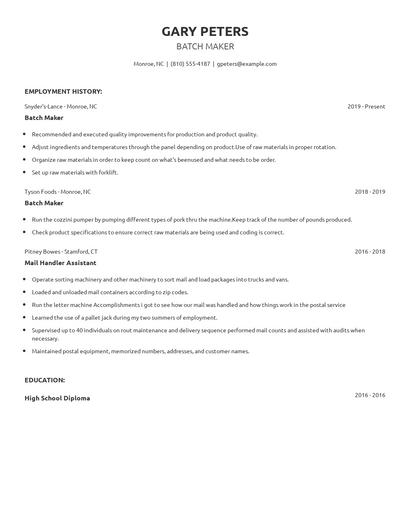

Choose from 10+ customizable batch maker resume templates

Build a professional batch maker resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your batch maker resume.Compare different batch makers

Batch maker vs. Mixer operator

A mixer operator deals with the blending of materials such as chemicals, tobacco, color pigments, liquids, and explosive ingredients. The tasks of a mixer operator include measuring ingredients and products to ensure they meet the stated requirements, tending to the machines used for mixing, and reading provided work orders to determine pertinent information. They also need to observe production and monitor the machines to ensure the operation is safe and efficient.

These skill sets are where the common ground ends though. The responsibilities of a batch maker are more likely to require skills like "batch ticket," "hazardous materials," "laboratory analysis," and "hazardous material handling." On the other hand, a job as a mixer operator requires skills like "food safety," "cleanliness," "mixers," and "pallet jack." As you can see, what employees do in each career varies considerably.

Mixer operators earn the highest salaries when working in the manufacturing industry, with an average yearly salary of $39,796. On the other hand, batch makers are paid more in the manufacturing industry with an average salary of $40,395.mixer operators tend to reach similar levels of education than batch makers. In fact, mixer operators are 0.3% more likely to graduate with a Master's Degree and 0.1% less likely to have a Doctoral Degree.Batch maker vs. Churn operator

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that batch maker responsibilities requires skills like "basic math," "safety procedures," "math," and "quality checks." But a churn operator might use other skills in their typical duties, such as, "pallets," "test products," "usda," and "flow rates."

Churn operators earn similar levels of education than batch makers in general. They're 0.4% less likely to graduate with a Master's Degree and 0.1% less likely to earn a Doctoral Degree.Batch maker vs. Brewing technician

The required skills of the two careers differ considerably. For example, batch makers are more likely to have skills like "basic math," "safety procedures," "math," and "gmp." But a brewing technician is more likely to have skills like "co2," "lab analyses," "continuous improvement," and "html."

Brewing technicians typically earn similar educational levels compared to batch makers. Specifically, they're 4.3% more likely to graduate with a Master's Degree, and 0.2% more likely to earn a Doctoral Degree.Batch maker vs. Blender

Types of batch maker

Updated January 8, 2025