What does a batching operator do?

A batching operator conducts quality assurance tests to ensure products comply with industry standards and customer orders. They have the responsibility to oversee the batching plant's daily operations, delegate duties among employees, monitor processes and provide instructions as necessary, and resolve issues and concerns should any arise. There are also times when they must coordinate with clients and suppliers, sign documents and delivery slips, and conduct maintenance checks on machines. Moreover, as a batching operator, it is essential to supervise staff while implementing the company's safety policies and regulations.

Batching operator responsibilities

Here are examples of responsibilities from real batching operator resumes:

- Manage distillation process to determine product specification compliance, and prepare unit for shutdown or turnaround process.

- Conduct employee trainings for compliance according to FDA regulations.

- Prepare USP-based products in compliance with current GMP clean room standards.

- Schedule production base on customer demands and blend per FDA guidelines.

- Maintain completion of up-to-date training classes on GMP, safety, and OSHA procedures and other duties as assigned!

- Used math to calculate formulas, make bulk cow/chicken feed with communication skills, used computer operations to mix feed

- Operate automate CIP sanitation systems.

- Move to the assembly department building electrical panels, installing electrical panels, installing various electrical devices on new centrifuges.

- Develop nimble and flex capacity approach with staffing scrutiny execution to traditional and legacy deploy CNC machining centers.

Batching operator skills and personality traits

We calculated that 10% of Batching Operators are proficient in Customer Orders, Basic Math, and GMP. They’re also known for soft skills such as Detail oriented, Math skills, and Physical strength.

We break down the percentage of Batching Operators that have these skills listed on their resume here:

- Customer Orders, 10%

Inventory accuracy, stocking replenishment and fulfilling of customer orders.

- Basic Math, 9%

Perform basic mathematical calculations as needed to ensure product quantities are accurately packaged.

- GMP, 9%

Meet and follow GMP Guidelines.

- Lot Numbers, 8%

Write down the lot numbers to each of the products.

- Product Quality, 8%

Inspected and ensured final product quality for finished goods.

- Math, 6%

Solve math equations quickly and accurately without calculator.

Most batching operators use their skills in "customer orders," "basic math," and "gmp" to do their jobs. You can find more detail on essential batching operator responsibilities here:

Detail oriented. One of the key soft skills for a batching operator to have is detail oriented. You can see how this relates to what batching operators do because "workers must be able to detect small changes in the quality or quantity of food products." Additionally, a batching operator resume shows how batching operators use detail oriented: "prepare and mix chemicals, additives as detailed in batching recipes. "

Math skills. Another soft skill that's essential for fulfilling batching operator duties is math skills. The role rewards competence in this skill because "workers may need math skills in order to accurately mix specific quantities of ingredients." According to a batching operator resume, here's how batching operators can utilize math skills in their job responsibilities: "used math to calculate formulas, made bulk cow/chicken feed with communication skills, used computer operations to mix feed"

Physical strength. batching operators are also known for physical strength, which are critical to their duties. You can see how this skill relates to batching operator responsibilities, because "food processing equipment workers must be able to lift or move heavy boxes of ingredients, which may weigh up to 50 pounds." A batching operator resume example shows how physical strength is used in the workplace: "controlled multiple chemical processes and physical plant operations utilizing instrumentation. "

The three companies that hire the most batching operators are:

- Sika10 batching operators jobs

- Niagara Bottling8 batching operators jobs

- The Kraft Heinz Company6 batching operators jobs

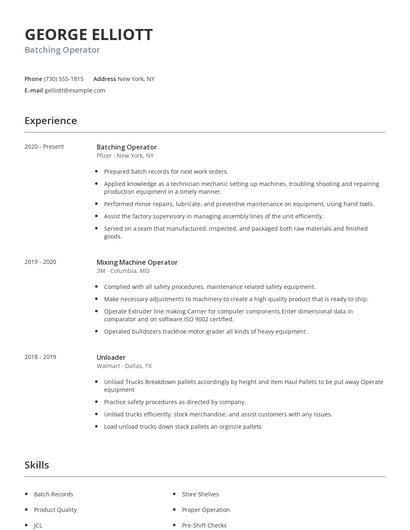

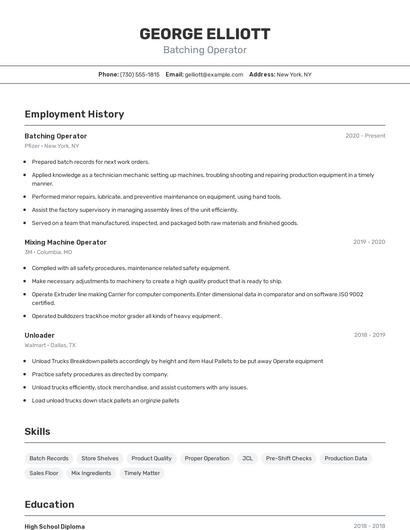

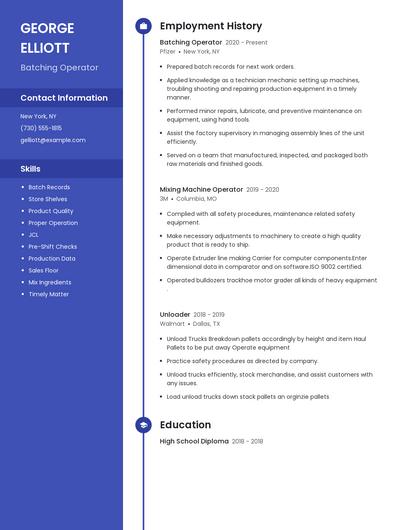

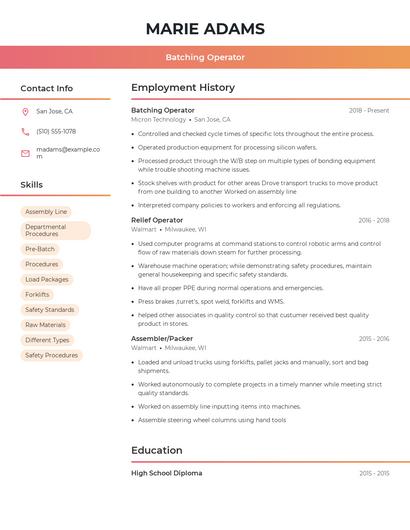

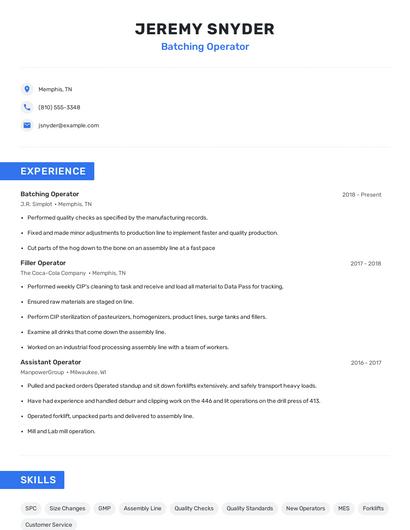

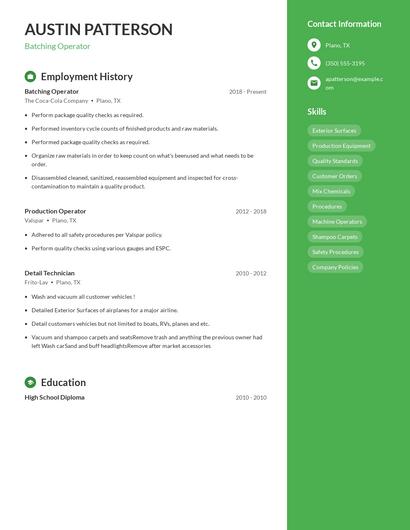

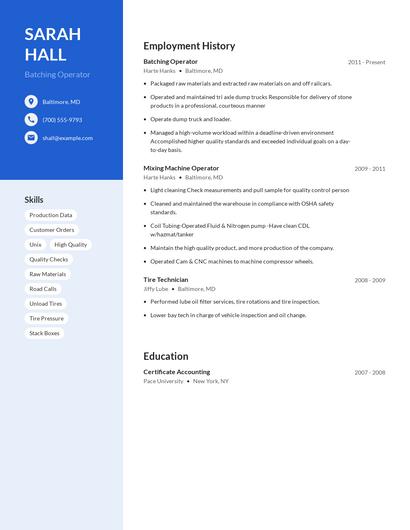

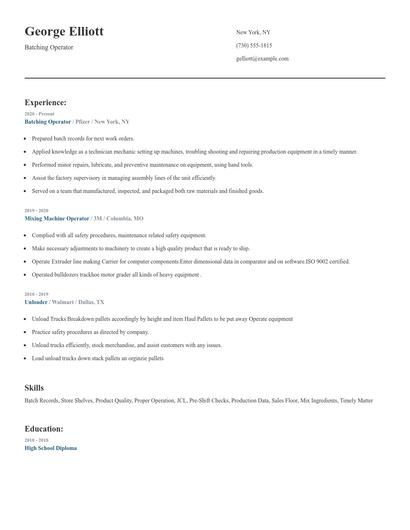

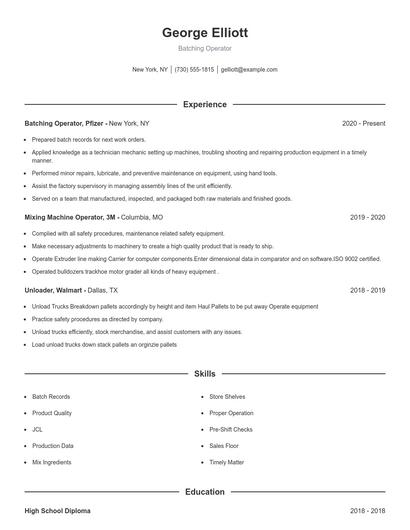

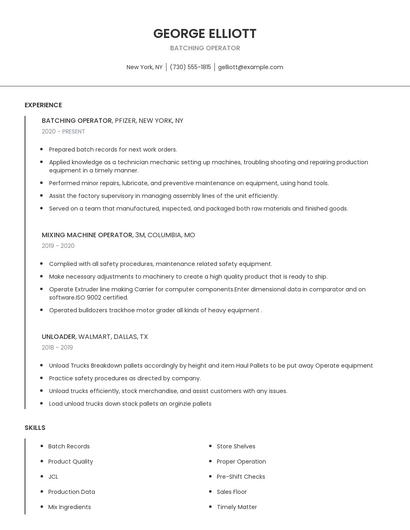

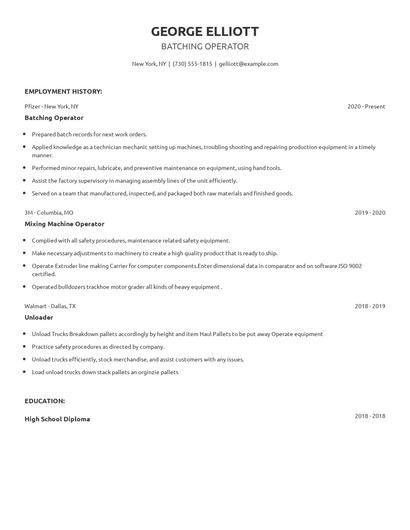

Choose from 10+ customizable batching operator resume templates

Build a professional batching operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your batching operator resume.Compare different batching operators

Batching operator vs. Mixer

In general, a mixer prepares dry chemicals and raw materials and combines them for use in safety boot manufacturing. Mixers provide training to work with chemicals under the regulations set by OSHA. They execute the sampling, documentation review, and inspection as required and necessary. Usually, they work in various departments while keeping with the standards. The skills and knowledge they need to develop include safety procedures, production schedules, and company policies.

While similarities exist, there are also some differences between batching operators and mixer. For instance, batching operator responsibilities require skills such as "customer orders," "routine maintenance," "production run," and "mainframe." Whereas a mixer is skilled in "mixers," "safety procedures," "work ethic," and "pallet jack." This is part of what separates the two careers.

Mixers tend to make the most money working in the finance industry, where they earn an average salary of $40,590. In contrast, batching operators make the biggest average salary, $42,454, in the manufacturing industry.mixers tend to reach similar levels of education than batching operators. In fact, mixers are 1.3% less likely to graduate with a Master's Degree and 0.0% less likely to have a Doctoral Degree.Batching operator vs. Blender

Production line operators must have strong reading skills and a knowledge base for loading and unloading, quality control, and starting and stopping of production lines. Those who choose this career will be expected to assist in assembling and manufacturing machines, foodstuffs, and products. Production line operators most often work in a factory setting for a manufacturer.

Each career also uses different skills, according to real batching operator resumes. While batching operator responsibilities can utilize skills like "routine maintenance," "production run," "mainframe," and "pre-batch," blenders use skills like "hand tools," "safety procedures," "production lines," and "lockout tagout."

Blenders may earn a lower salary than batching operators, but blenders earn the most pay in the agriculture industry with an average salary of $39,608. On the other hand, batching operators receive higher pay in the manufacturing industry, where they earn an average salary of $42,454.In general, blenders achieve similar levels of education than batching operators. They're 0.2% more likely to obtain a Master's Degree while being 0.0% more likely to earn a Doctoral Degree.Batching operator vs. Batch room technician

The required skills of the two careers differ considerably. For example, batching operators are more likely to have skills like "customer orders," "lot numbers," "product quality," and "math." But a batch room technician is more likely to have skills like "patients," "patient care," "data entry," and "cleanliness."

Batch room technicians earn the best pay in the technology industry, where they command an average salary of $49,106. Batching operators earn the highest pay from the manufacturing industry, with an average salary of $42,454.When it comes to education, batch room technicians tend to earn similar degree levels compared to batching operators. In fact, they're 0.5% more likely to earn a Master's Degree, and 0.0% more likely to graduate with a Doctoral Degree.Batching operator vs. Production line operator

Types of batching operator

Updated January 8, 2025