Automatically apply for jobs with Zippia

Upload your resume to get started.

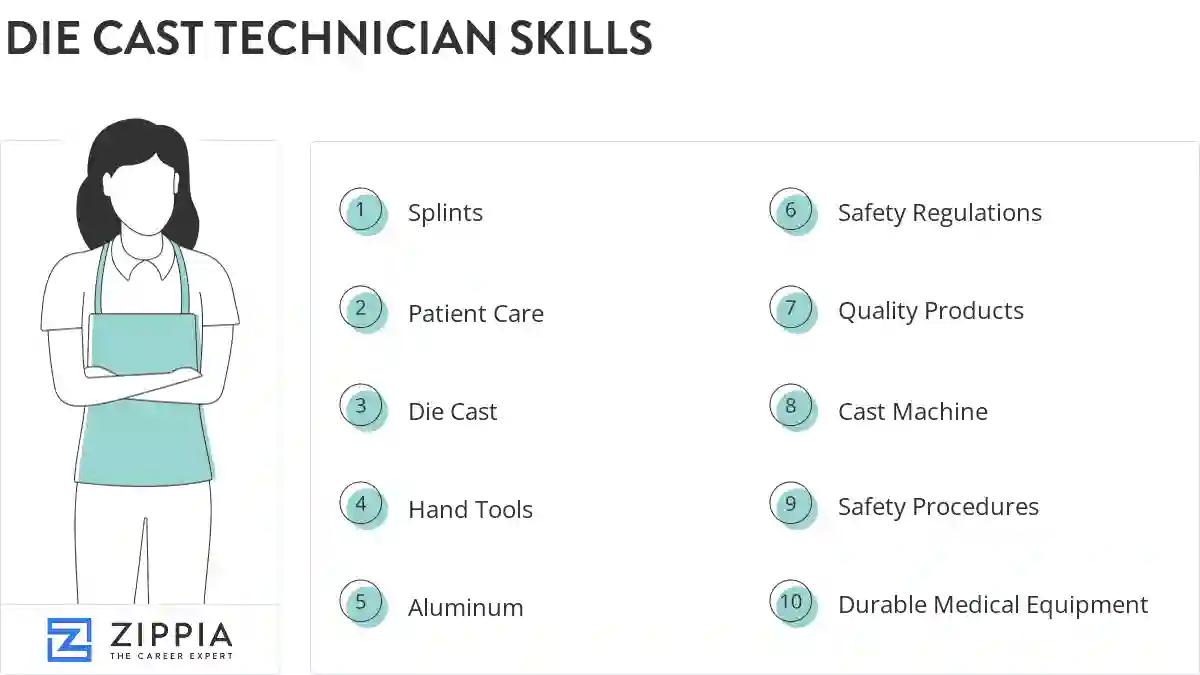

Die cast technician skills for your resume and career

15 die cast technician skills for your resume and career

1. Splints

- Assisted physicians and nursing personnel with orthopedic casting procedures including the application and removal of a variety of casts and splints.

- Fabricated, modified, and removed various types of casts and splints, both plaster and synthetic.

2. Patient Care

Patient care entails the diagnosis, recovery, and control of sickness as well as the maintenance of physical and emotional well-being through the use of healthcare providers' services. Patient care is described as services provided to patients by health practitioners or non-professionals under guidance.

- Provided excellent patient care to children and adults.

- Organized the medical environment, performed and directed support activities in-patient care situations including contingency operations and disasters.

3. Die Cast

- Functioned variously as Certified Production Technician operating automatic die cast machines and machining centers.

- Die Cast Systems Technician: Maintain systems in Die Cast including furnace's MPH, Modern and Laundry systems.

4. Hand Tools

- Skimmed slag or remove excess metal from full ladles or molds using hand tools, strainers, rakes, or burners.

- Installed or replaced both mechanical/electrical/electronic components using hand tools.

5. Aluminum

Aluminum is the most common nonferrous metal and the most prevalent metallic material in the Earth's crust. Aluminum is never found in its metallic form in nature, but its compounds can be found in varying degrees in nearly all minerals, vegetation, and animals. Cans, foils, cooking utensils, door frames, kegs, and aeroplane pieces are all made of aluminum.

- Performed quality control inspections of zinc and aluminum molds and castings.

- Cast aluminum and mixed metal parts.

6. Safety Regulations

- Operated fork truck, complied with safety regulations, maintained clean area

- Handled hazardous waste materials and upheld safety regulations.

Choose from 10+ customizable die cast technician resume templates

Build a professional die cast technician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your die cast technician resume.7. Quality Products

A quality product satisfies the client's intended need and matches the cost the consumer paid for it.

- Adhere to company and government standards for safety and production of quality products.

- Assisted members of management on scheduling and troubleshooting presses to assure that quality products were being produced.

8. Cast Machine

- Perform changeovers and setups on cold chamber Diecast machines and trim presses.

9. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Complied with safety procedures including use of required safety equipment and identified unsafe practices or conditioned faults and resolved equipment issues.

- Spearheaded the development of work instructions and safety procedures along with implementing cost cutting retrofits that improved safety, and efficiency.

10. Durable Medical Equipment

- Assist in other areas when needed, such as front desk/patient check in and durable medical equipment department.

- Fit and correctly size durable medical equipment.

11. Production Equipment

Production equipment in limited terms is used to define any type of machinery or equipment used in the production of a video or film. Basic production equipment includes a camera, tripod, lighting kit, camera light, short term microphone, light reflector, boom pole, shock mount, audio cables, wireless microphone, headphones, portable digital audio recorder, camera lenses, extra batteries, external hard drive, and DSLR shoulder mount rig.

- Assisted engineers in the repair, adjustment, changeover, and upgrades of various types of fabrication and production equipment.

- Accepted and transported deliveries of supplies, furniture, Movie set production equipment.

12. Cast Process

- Conduct preliminary operational start up making mechanical and computer adjustments to the varying operational machines for the die cast process.

- Detailed knowledge of die cast process, including die preparation, filling and ejection.

13. Routine Maintenance

- Press operator; Qualified to read print and calculate measurements Performed routine maintenance to make repairs according to specification

- Perform basic troubleshooting and routine maintenance of audio/video equipment as well as in cabin television troubleshooting on-board ships.

14. Cast Tech

- Create yearly schedule for cast tech staffing.

15. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Work with CNC machines such as Mazak, Toyoda, Excello, Hurricane, and Prince Machines.

- up Responsibilities include: Operation of CNC lathes.

5 Die Cast Technician resume examples

Build a professional die cast technician resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your die cast technician resume.

What skills help Die Cast Technicians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of die cast technician skills to add to your resume

The most important skills for a die cast technician resume and required skills for a die cast technician to have include:

- Splints

- Patient Care

- Die Cast

- Hand Tools

- Aluminum

- Safety Regulations

- Quality Products

- Cast Machine

- Safety Procedures

- Durable Medical Equipment

- Production Equipment

- Cast Process

- Routine Maintenance

- Cast Tech

- CNC

- Stamping Dies

- Visual Inspections

- Process Control

- Cast Application

- Vital Signs

- Knockout

- Tig Welding

- TIG

- Surgical Procedures

- Quality Standards

- FANUC

- Extrusion

- PLC

- Jigs

- Production Runs

- Continuous Improvement

- Machine Operators

- Torches

- Hoists

- Cast Room

Updated January 8, 2025