Automatically apply for jobs with Zippia

Upload your resume to get started.

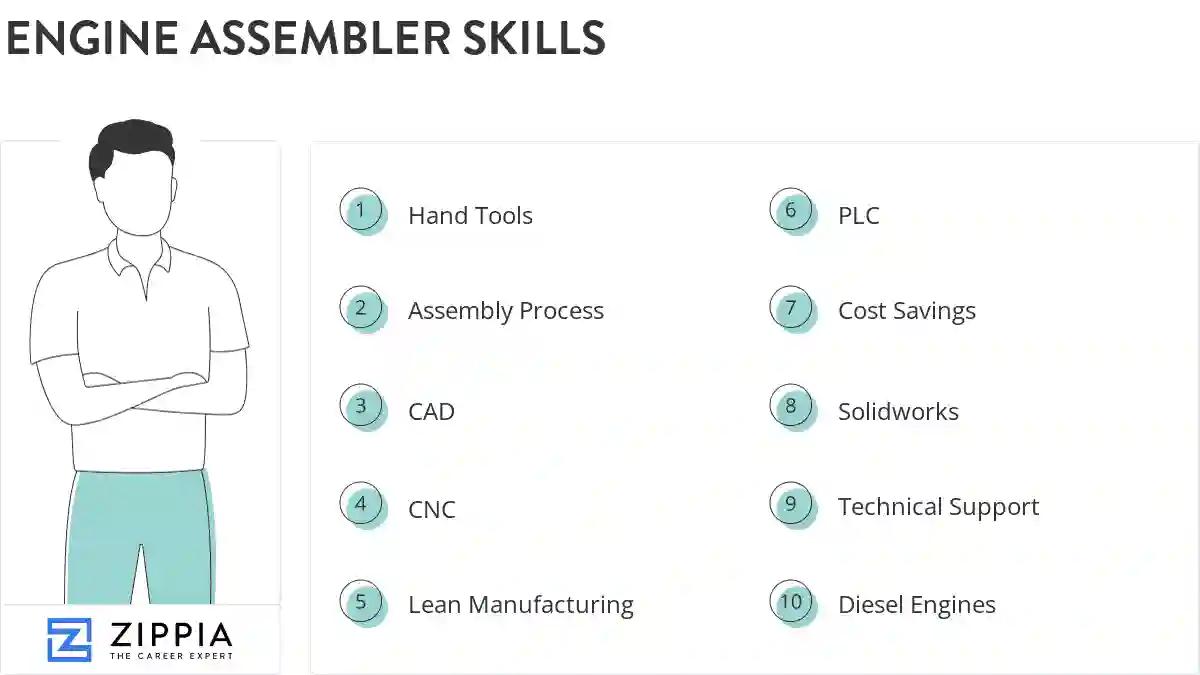

Engine assembler skills for your resume and career

15 engine assembler skills for your resume and career

1. Hand Tools

- Solder components to PC board, Crimping/stripping wires, handle power tools and hand tools, trouble-shooting.

- Used various types of special jigs, fixtures, hand tools, and small air powered tools.

2. Assembly Process

- Standardized the assembly process through workstation layout planning and optimization.

- Managed assembly process of projects, and coordinated efforts of designer's, machine shops, and outside vendors.

3. CAD

- Exposed to solid works and CAD design for packaging machines.

- Remember various tractor options according to the operation method sheet, and build according to Team Center (CAD) software.

4. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Verify parts clearances.. Cnc cylinder blocks and cylinder heads Repair or replace damaged parts.

- Performed basic editing, offsets/insert maintenance and adjustments on CNC vertical machining centers and lathes to maintain quality and production rates.

5. Lean Manufacturing

- Design and implement lean manufacturing processes and work stations including, kan ban, assembly work cells and assembly lines.

6. PLC

- Installed and tested Allen Bradley PLC's as a general rule.

- Installed and programmed Programmable Logic Circuits (PLC).

Choose from 10+ customizable engine assembler resume templates

Build a professional engine assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your engine assembler resume.7. Cost Savings

- Recommended assembly plant processing changes amounting to annual cost savings of 1.7 million dollars per plant.

- Devised corrective actions to resolve quality issues resulting in higher quality product and cost savings.

8. Solidworks

- Design and implement tooling and material handling for equipment using AutoCAD and SolidWorks.

- Created and revised assembly drawings using AutoCAD and Solidworks to clarify system assembly, construction, and requirements.

9. Technical Support

Technical support or tech support are the services provided by any hardware or software company to users. They help in solving the technical difficulties the customers face with their products or services. Moreover, the tech support employees maintain, manage, and repair the IT faults. They are also responsible for resolving the network problems, installing and configuring hardware and software.

- Provide technical support to the technical team.

10. Diesel Engines

Diesel engines use an internal combustion technique that burns diesel oil in hot compressed air to propel a machine.

- Worked many positions assembling diesel engines on an assembly line

- Repair, rebuild and light diagnostics of 710 and 645 diesel engines.

11. Product Design

Product design can be described as a process of imagining, creating, and iterating products that solve user's problems and talk about the specific needs of users in the market. Product design is an engineering disciple and it is the basic design and idea that goes before the mass production of the product.

- Analyze product design to assure quality and reliability.

- Assisted engineers from design of vehicle to program launch on Ford Freestyle/500, incorporating product design into manufacturing processes.

12. Air Tools

- Read blueprints, assembled copper parts for electrical equipment using hand tools and air tools, and handled material with forklift.

- Use various hand, power, and air tools to assemble parts on door frame while the assembly line keeps moving.

13. Assembly Problems

- Resolve assembly problems by altering dimensions to meet specifications; notifying supervisor to obtain additional resources.

- Assisted customers with custom solutions to potential design and assembly problems.

14. Assembly Equipment

- Developed robotic based assembly equipment in a R&D team specializing in producing new manufacturing equipment.

- Job requirements includes project planning, design unique assembly equipment, estimate and control equipment budget.

15. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Reduced alignment warranty by 30% using design for 6 Sigma practices to design new tooling and process.

- Lead Six Sigma projects/Kaizan events for improvements to supplierquality and manufacturing processes affecting NVH.

5 Engine Assembler resume examples

Build a professional engine assembler resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your engine assembler resume.

What skills help Engine Assemblers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of engine assembler skills to add to your resume

The most important skills for an engine assembler resume and required skills for an engine assembler to have include:

- Hand Tools

- Assembly Process

- CAD

- CNC

- Lean Manufacturing

- PLC

- Cost Savings

- Solidworks

- Technical Support

- Diesel Engines

- Product Design

- Air Tools

- Assembly Problems

- Assembly Equipment

- Sigma

- BOM

- Process Control

- Failure Analysis

- Engine Components

- Toyota

- Engineering Changes

- Laser

- SPC

- Quality Issues

- Assembly Procedures

- Hoists

- Engineering Support

- Jigs

- PCB

- Electrical Components

- SMT

- Hydraulic Press

- Circuit Boards

- Surface Mount

- Clean Room Environment

- Blueprint Specifications

- Continuous Improvement

- Quality Checks

- Honda

- Quality Standards

- Machine Capabilities

- Clips

- Rough Spots

- Chrysler

- Specifications Manuals

- Customer Specifications

- Assembly Blueprints

Updated January 8, 2025