Automatically apply for jobs with Zippia

Upload your resume to get started.

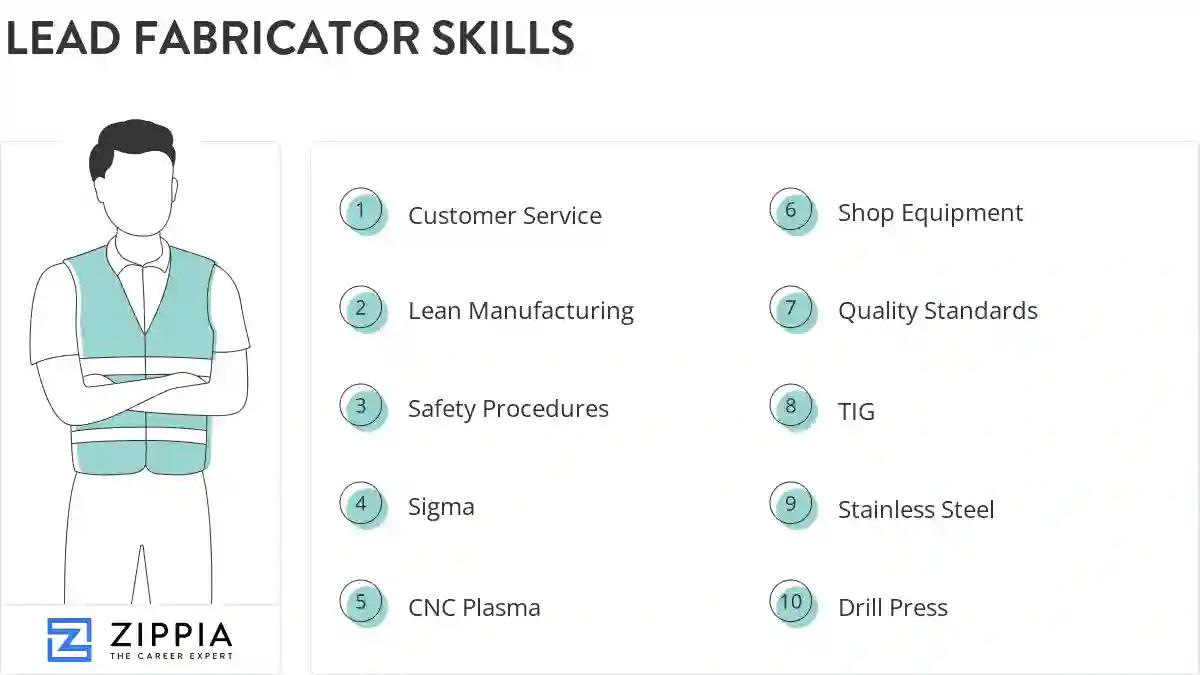

Lead fabricator skills for your resume and career

15 lead fabricator skills for your resume and career

1. Customer Service

Customer service is the process of offering assistance to all the current and potential customers -- answering questions, fixing problems, and providing excellent service. The main goal of customer service is to build a strong relationship with the customers so that they keep coming back for more business.

- Shop management of other employees and ongoing projects, customer service, packaging of orders, and monitoring of inventory.

- Stone fabrication * Customer service * Open/close shop * Shop maintenance * Forklift operation

2. Lean Manufacturing

- Worked various projects, process improvements, lean manufacturing.

- Implement lean manufacturing practices throughout the department.

3. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Initiated shop safety procedures and developed production area layout.

- Educate and train employees on proper equipment operation, work and safety procedures, and cross-training.

4. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Monitored and reported supplier quality using Six Sigma project tools

- Applied six sigma process to production in order to improve work flow productivity.

5. CNC Plasma

- Set up certification tests for all employees.Quality control shift manager for several years.Operation of CNC plasma cutter

- Trained workers on CNC plasma, welders, shears, press brake and other equipment within department.

6. Shop Equipment

Shop Equipment refers to the collection of items and tools that a (usually brick-and-mortar) business keeps and utilises in providing their services, maintaining their surroundings, or when selling their wares. While this equipment might consist simply of just some fridges, a till, and some cleaning supplies like in everyday grocery shops, more specific and specialised businesses might also make frequent use of saws, lawnmowers, freezers, bikes and cars, and heavy machinery such as rollers and cranes.

- Use of different shop equipment safely and apropriately ex.

- Hired as an entry level fabricator and assigned various duties welding and operating shop equipment

Choose from 10+ customizable lead fabricator resume templates

Build a professional lead fabricator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your lead fabricator resume.7. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Ensured all company and industry regulated quality standards are maintained on all fabricated equipment.

- Monitor production quality and process control to assure product meet quality standards

8. TIG

TIG stands for "tungsten inert gas welding" and is also known as gas tungsten arc welding (GTAW). This particular type of weld is more difficult as it requires the welder to heat materials until they are liquid.

- Quoted jobs, welded TIG, MIG, aluminum and steel.

- Selected materials and equipment required for MIG and Tig welding.

9. Stainless Steel

Stainless steel is an alloy of iron, chromium, carbon, and some other metals with corrosion-resistant properties. The components of steel include less than 1% carbon, 1% manganese, and small quantities of other elements such as phosphorus, silicon, sulfur, and oxygen. Iron and carbon are the two essential components of steel. Stainless steel is resistant to tarnishing and rust.

- Performed cutting, welding and installation of fine metal Implements including stainless steel, aluminum, bronze and nickel.

- Field welding was done regularly because we conducted our own installation of custom stainless steel equipment.

10. Drill Press

A drill press refers to a device used to produce holes in hard substances. When drilling the holes, you need to clamp the workpiece on a table and hold the drill in a rotating spindle and feed it into the workpiece.

- Operated machinery including: lathes, drill presses, band saws and various power tools, read blue prints.

- Used metal breaks, band saw, drill press, and plasma arc to create and form new components.

11. Solidworks

- Performed an FEA study in SolidWorks to vet the suspension design for Federal Motor Vehicle Safety Standards.

- Design of chassis was done using Solidworks and analyzed with Ansys.

12. Arc Welding

- Use processes including gas metal arc and shielded metal arc welding to produce rod iron gates, and chain-link gates.

- Experienced in shielded metal arc welding involving transformer lid applications.

13. Tape Measure

A tape measure is a thin, flexible strip of plastic or metal that can be rolled up when it is not being used. The tape measure has numbers marked on it linearly which is used for measuring length.

- Die Cutting - Reading Caliper, Tape measures etc.

- Use a plasma cutter, caliper and tape measure frequently.

14. Jigs

- Developed jigs, dies, fixtures, gauges and other tooling to meet specifications set out by customers.

- Clamped, measured and aligned metal parts in Jigs prior to welding.

15. Brake Press

- Organized the turret and brake press tooling and programming set ups to be more efficiently utilized.

- Worked with R&D on brake press prototype jobs and first run capabilities.

5 Lead Fabricator resume examples

Build a professional lead fabricator resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your lead fabricator resume.

What skills help Lead Fabricators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of lead fabricator skills to add to your resume

The most important skills for a lead fabricator resume and required skills for a lead fabricator to have include:

- Customer Service

- Lean Manufacturing

- Safety Procedures

- Sigma

- CNC Plasma

- Shop Equipment

- Quality Standards

- TIG

- Stainless Steel

- Drill Press

- Solidworks

- Arc Welding

- Tape Measure

- Jigs

- Brake Press

- Band Saws

- Production Process

- Customer Specifications

- Tig Welding

- Auto CAD

- GMAW

- SMAW

- Plasma Arc

- Hoists

- Carbon Steel

- Industrial Maintenance

- Production Schedules

- FCAW

- Laser Cutting

- HVAC

- Mild Steel

- Structural Steel

- GTAW

- RAN

- Shop Drawings

- Sketch

- Engineering Drawings

- Inventory Control

- Troubleshoot

- Torches

- Flux Core

- Punch Press

- Production Runs

- Production Lines

- Machine Shop

- Quality Checks

- Production Floor

Updated January 8, 2025