Automatically apply for jobs with Zippia

Upload your resume to get started.

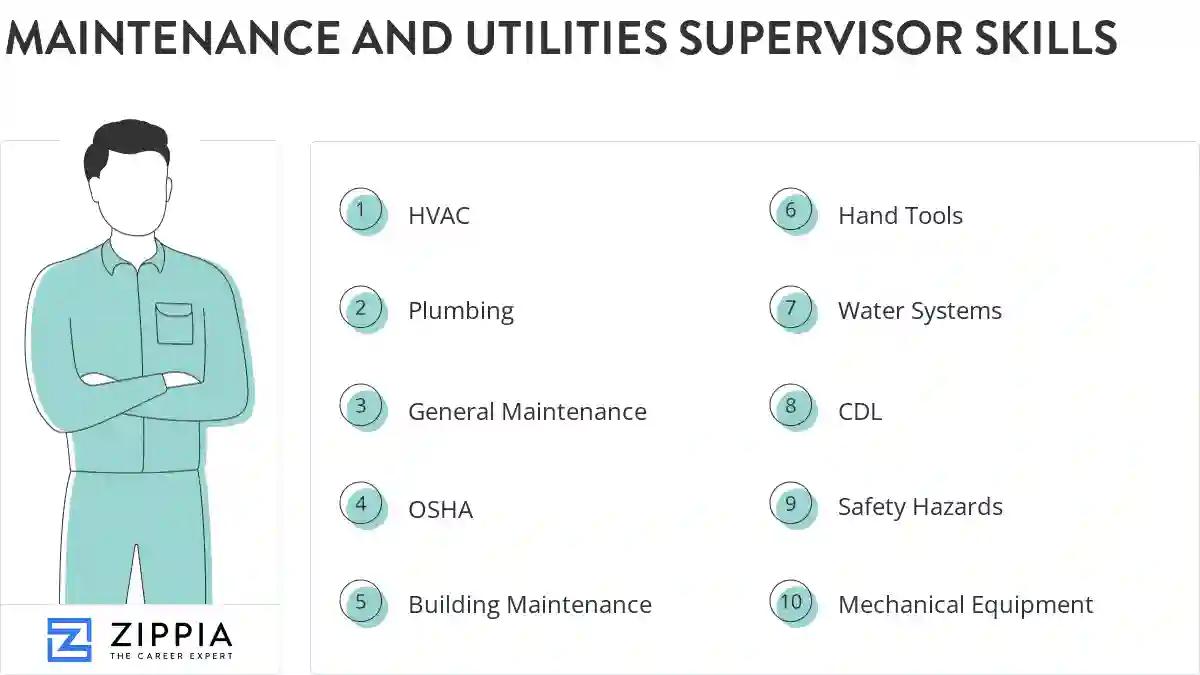

Maintenance and utilities supervisor skills for your resume and career

15 maintenance and utilities supervisor skills for your resume and career

1. HVAC

- Prepare budgets for HVAC & Utilities activities (Projects and daily PM activities).

- Supervised union craftsmen to include Millwrights, Electricians, Instrument Technicians, Pipefitters, HVAC Mechanics, and Stationary Engineers.

2. Plumbing

- Repaired and maintained machinery, plumbing, physical structure, electrical wiring and fixtures and all water systems.

- Repair Water Heaters, Plumbing, Buildings, Air Conditioned Systems.

3. General Maintenance

General maintenance is the regular check-up and repairs of machinery, buildings, and other mechanical equipment. General maintenance is performed by repair workers who are skilled to handle the day-to-day defects produced in the machinery. General maintenance aims to make sure the items remain in the best operational conditions. Usually, a set of planned activities are performed regularly by an expert to monitor the maintenance.

- Communicate with staff, administrators, vendors and others regarding general maintenance and custodial needs.

- General Maintenance Work Packages, Maintenance of on site and off site buildings

4. OSHA

- Participated in the site receiving OSHA VPP Star Award.

- Worked with OSHA, EQB, PRASA, RCRA and EPA Regulations.

5. Building Maintenance

Building maintenance means all duties necessary to keep a building livable and functional. It involves removing trash regularly, repairing broken items, and cleaning common areas.

- Achieve financial objectives by preparing a building maintenance annual budget, scheduling expenditures and performing project forecasting & estimating.

- Managed and maintained building maintenance requiring key and timely planning, ensuring equipment and supply inventory was at desired level.

6. Hand Tools

- Gained experience using hand tools, professionally documenting work orders, and meeting with supervisors to discuss quality.

- Repaired or replaced defective equipment parts, using hand tools and power tools, and reassembled equipment.

7. Water Systems

Water systems refer to any plumbing or equipment that filters or cleans water as it passes through a city or other residential area. As much of the water used in residential areas pass through a series of sewer pipes and other plumbing, there are many associations that monitor the cleanliness of the water. In order to do this, water may be treated with filtration pumps, softeners, and other methods of disinfection to ensure the water is safe to drink and use.

- Investigated/resolved discrepancies on process water systems, controlled environments, and final product particulate analysis for validated equipment in conjunction with

- Developed and executed analysis to reduce energy consumption of steam, compressed air and chilled water systems.

8. CDL

- Operate equipment and vehicles requiring a CDL.

9. Safety Hazards

Safety hazards are defined as any potential source of danger or harm to a person's health and safety. The term commonly refers to the risks associated with the kind of occupation or work. The five common types of occupational safety hazards are; biological (health risks from viruses, bacteria, insect,s, etc.), chemical (dangerous substances used in manufacturing plants), physical (risk of injury associated with labor), Ergonomic (worker's efficiency during work), and Psychosocial (mental health risks involved with certain occupations).

- Observe and report safety hazards and need for maintenance and repair.

10. Mechanical Equipment

Mechanical equipment is a term referring to the machinery which have been created and gathered for the purpose of fulfilling one or more functions and consisting of, most often, multiple components.

- Implemented a preventive maintenance program on air handlers and pool mechanical equipment reviving failing equipment and restoring full function.

- Supervised, directed and performed troubleshooting, repair, replacement, and servicing of electrical and mechanical equipment.

11. Facility Maintenance

- Promoted to On Site Lead Manufacturing Mechanic & Facility Maintenance Installation of machinery related to production, packaging, and refrigeration.

- Managed five maintenance groups including four different manufacturing maintenance departments as well as the facility maintenance for the Dallas manufacturing facility.

12. Industrial Maintenance

- Organize and supervise daily operations for the industrial maintenance department for a continuous production facility.

- Employed as an industrial maintenance supervisor (Foreman) in an aluminum foil manufacturing facility.

13. Utilities Equipment

- Enhanced organizational capabilities by supporting 43 external operations with utilities equipment and personnel.

- Managed the training and activities of personnel engaged in operation, maintenance, and repair of Utilities Equipment.

14. Plant Maintenance

Plant maintenance includes all preventive measures, processes, and operations concerned with plant life.

- Trained with plant maintenance on small projects to become familiar with plant operations and equipment.

- Managed 79 personnel in plant maintenance, including 7 manufacturing operations and an automated shipping and storage operation.

15. Water Treatment Plant

Water treatment refers to the process of improving water quality in a way that it becomes appropriate for a specific use. The uses maybe industrial water supply, irrigation, drinking, water recreation or river flow maintenance. The water treatment process usually removes contamination from an undesirable component, if not completely then at least partially.

- Provided support to the Waste Water Treatment Plant.

- Helped to modify a Ploogloo aeration system within a pond system in wastewater treatment plant.

What skills help Maintenance And Utilities Supervisors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of maintenance and utilities supervisor skills to add to your resume

The most important skills for a maintenance and utilities supervisor resume and required skills for a maintenance and utilities supervisor to have include:

- HVAC

- Plumbing

- General Maintenance

- OSHA

- Building Maintenance

- Hand Tools

- Water Systems

- CDL

- Safety Hazards

- Mechanical Equipment

- Facility Maintenance

- Industrial Maintenance

- Utilities Equipment

- Plant Maintenance

- Water Treatment Plant

- Cooling Towers

- Compressed Air Systems

- Maximo

- Construction Projects

- Capital Projects

- FDA

- Management System

- Sigma

- GMP

- Safety Regulations

- CAPA

- USP

Updated January 8, 2025