Automatically apply for jobs with Zippia

Upload your resume to get started.

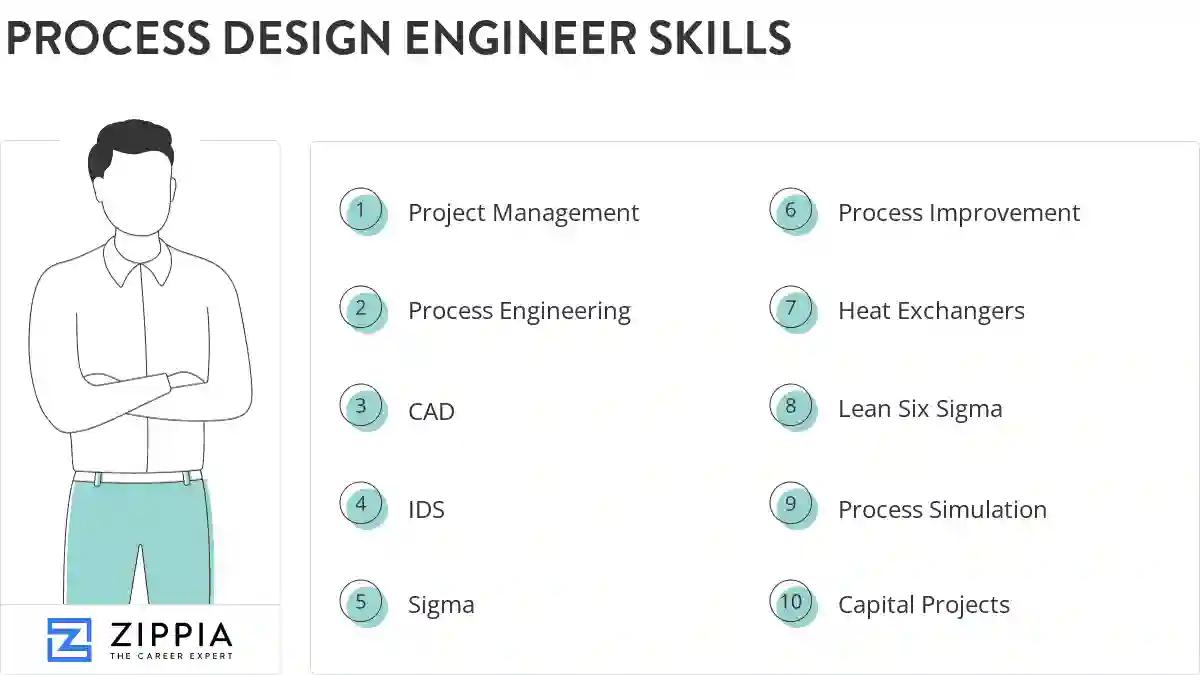

Process design engineer skills for your resume and career

15 process design engineer skills for your resume and career

1. Project Management

- Advanced from production engineering group to support the pet food group project director with technical design details and project management.

- Project Management experience included programming (laser or turret) and prototypes for vending machines.

2. Process Engineering

Process engineering is the agreement and use of the essential standards and laws of nature that permit us to change crude material and energy into items that are valuable to society, at a mechanical level.

- Provide Process Engineering support to sales group by performing preliminary design calculations, reviewing customer specifications, and obtaining technical quotes.

- Process Engineering in the automation of a plastic extrusion manufacturing facility.

3. CAD

- Developed graphic data compression/expansion and translation algorithms for use with CAD, CAM, CALS, facsimile, and document architecture.

- Create solid models and design parts and assemblies for forging bolsters including die clamping and ejection systems using SolidWorks CAD.

4. IDS

An IDS (intrusion detection system) stands for a software application or device that monitors a network to identify policy violations or malicious activities.

- Reviewed P & IDs and Conducted assigned process design, prepared engineering calculations.

- Developed P & IDs for EO unit chilled water system, unit compression systems and Ethanol storage tank and unloading system.

5. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Incorporated Six Sigma methodology and principles by using the DMACIC process for quality and productivity improvement.

- Conducted troubleshooting for malfunctioning refrigeration equipment using Six Sigma methodology.

6. Process Improvement

- Created reports based on analysis & process improvement recommendations without jeopardizing risk to the portfolio while improving customer and associate experience.

- Analyzed, interpreted, implemented and updated processes by utilizing sound process improvement models and techniques.

Choose from 10+ customizable process design engineer resume templates

Build a professional process design engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your process design engineer resume.7. Heat Exchangers

A heat exchanger is used to transfer heat from one medium to another. The heat exchanger is used in both the heating and cooling process.

- Conducted evaluations of Distillation Columns and Heat Exchangers.

- Composed design specification packages to purchase heat exchangers.

8. Lean Six Sigma

- Maintained daily planet operation, performed and analyze lean six sigma methodology.

- Trained on Lean Six Sigma techniques & a leader of a RIE team, delivering an annual savings of $20,000.

9. Process Simulation

- Implemented steady state chemical process simulations in Aspen Plus and adjusted models to match experimental data by tuning simulation parameters.

- Build process simulations using Aspen Plus to model process technology developments.

10. Capital Projects

A capital project is a long-term project carried out by professional teams to build, improve, maintain or develop a huge project that will help improve the asset of a city. This project involves a significant and constant flow of investments. A capital project can be new construction, the purchase of land or property, leasing a property, the renovation of an existing building, or the purchase of new equipment.

- Developed detailed estimates (+/-10%) for more than 60 small capital projects (<$1 million).

- Developed 40+ technically innovative designs through Capital Projects gating system, for new and revamped facilities.

11. Solidworks

- Sketched and assembled in SolidWorks to create blueprint and 3D Model for motion and stress analysis.

- Designed sheet metal assemblies in SolidWorks, completed drawings for these large assemblies.

12. Business Process

A business process is a group of tasks that are performed by people working in a business to attain a worthy product and to present it to their customers. A business process can also be defined as performing several steps to achieve a certain goal set by a company. Business processes need to set purposeful goals and the outcome of that goal should be clear.

- Developed new business processes where no formal process existed to optimize efficiency and consistency throughout the organization.

- Project Description: Working on developing software for business process automation using RPA technology concepts.

13. Equipment Specifications

- Completed equipment specifications, sizing and rating.

- Prepared hydraulic tabulations and equipment specifications.

14. Aspen Plus

- Learn and implement various options available within Aspen Plus simulator to more accurately describe processes being developed.

- Used actual plant data to simulate chemical process using Aspen Plus, Aspen Dynamics, and regressed VLE.

15. Design Engineering

- Tested computer automation for design engineering consistency.

- Assisted with Design Engineering Projects, including products, parts, and components.

5 Process Design Engineer resume examples

Build a professional process design engineer resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your process design engineer resume.

What skills help Process Design Engineers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

What skills stand out on process design engineer resumes?

Charles Jenckes

Assistant Professor, University of North Carolina at Charlotte

1.Where the candidate went to school and what was studied

2.GPA

3.Any successful internships

4.Projects completed by the student

What process design engineer skills would you recommend for someone trying to advance their career?

Director, Undergraduate Programs & Associate Teaching Professor, North Carolina State University

What type of skills will young process design engineers need?

Director, Center for Air Transportation Systems Research Assoc. Professor, System Engineering and Operations Research Dept., George Mason University

Too many times we rush in with a technology solution that does not really solve the problem.

Also go and listen to the stakeholders. Understand their perspectives and account for these perspectives in the design solution.

Too many times we rush in with a technology solution that causes more problems than it solves because we have not truly understood the perspectives of the stakeholders.

What technical skills for a process design engineer stand out to employers?

Adjunct Instructor, Clarkson University

Respectfully, today's graduates do not understand that being able to text and use social media does not prepare them for "real" computer skills. Many students that I have in high school and in college do not have proper writing skills, document formatting skills, or document management skills to know how to save documents properly and where to save to.

What soft skills should all process design engineers possess?

Professor, South Dakota School of Mines and Technology

What hard/technical skills are most important for process design engineers?

Dr. David Grewell Ph.D.

Department Chair and Professor, North Dakota State University

List of process design engineer skills to add to your resume

The most important skills for a process design engineer resume and required skills for a process design engineer to have include:

- Project Management

- Process Engineering

- CAD

- IDS

- Sigma

- Process Improvement

- Heat Exchangers

- Lean Six Sigma

- Process Simulation

- Capital Projects

- Solidworks

- Business Process

- Equipment Specifications

- Aspen Plus

- Design Engineering

- Process Flow Diagrams

- Process Control

- Design Process

- P Id

- Process Equipment

- Process Systems

- R

- Instrumentation Diagrams

- PFDs

- HAZOP

- Engineering Drawings

- Distillation

- Technical Support

- Chemical Process

- Engineering Support

- Relief Valves

- System Design

- Product Design

- Material Balances

- Aspen

- Cost Estimates

- Data Sheets

- MATLAB

- CNC

- Gas Processing

- PHA

- Equipment Design

- FMEA

- Verilog

- FPGA

- FDA

- Cadence Virtuoso

- ISO

Updated January 8, 2025