What does a production line assembler do?

Production line assembler responsibilities

Here are examples of responsibilities from real production line assembler resumes:

- Achieve enhancement in shop math: trigonometry, compound angles, and geometry.

- Utilize power tools under ISO policy procedures.

- Perform various assembly, sub-assembly, and or packaging operation in a production area requiring general physical dexterity.

- Assemble and package disposable plastic hospital products, such as hypodermic syringes, catheters and intravenous apparatus.

Production line assembler skills and personality traits

We calculated that 25% of Production Line Assemblers are proficient in Safety Standards, Assembly Process, and Quality Checks.

We break down the percentage of Production Line Assemblers that have these skills listed on their resume here:

- Safety Standards, 25%

Produce a quality product that meets the required work regulated specifications and government regulated safety standards.

- Assembly Process, 19%

Executed all aspects of the manufacturing and assembly process of a Class III Implantable Medical Device.

- Quality Checks, 7%

Perform quality checks on parts to verify they function properly.

- Quality Standards, 5%

Team members must be able to evaluate parts and hardware to determine quality standards prior to installation.

- Safety Guidelines, 5%

Produced various interior parts for 2011/2012 Dodge Ram automobiles, adhering to quality and safety guidelines.

- RAN, 3%

Replaced temper seal, tape, and labels when the machines ran out.

"safety standards," "assembly process," and "quality checks" are among the most common skills that production line assemblers use at work. You can find even more production line assembler responsibilities below, including:

The three companies that hire the most production line assemblers are:

- Express Employment Indy South3 production line assemblers jobs

- Aerotek1 production line assemblers jobs

- Peoplelink Staffing Solutions1 production line assemblers jobs

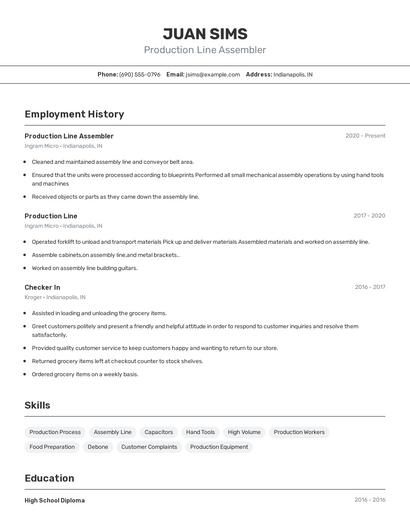

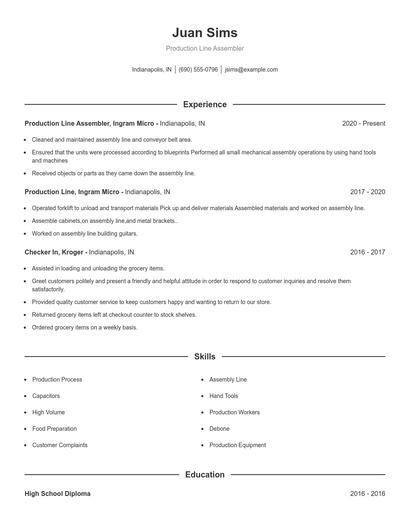

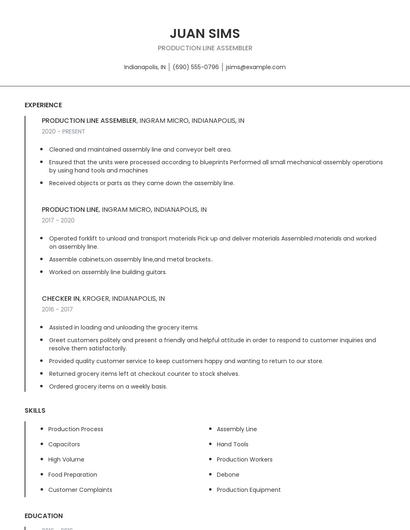

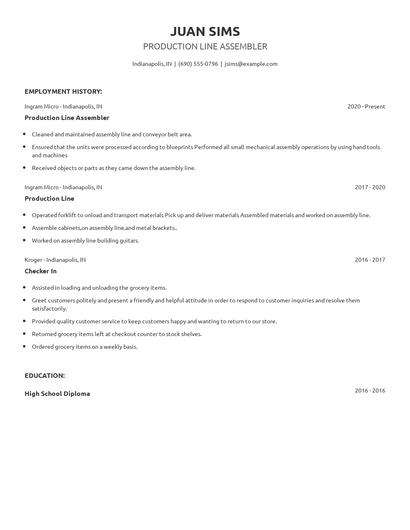

Choose from 10+ customizable production line assembler resume templates

Build a professional production line assembler resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your production line assembler resume.Compare different production line assemblers

Production line assembler vs. Line operator

A line operator is responsible for assisting in warehouse and factory operations, usually assigned on doing heavy works for the production. Line operators' duties include operating manufacturing machines and equipment, placing products on the appropriate shelves, checking supplies and inventories, loading orders for shipments, inspecting products for any defects, labeling products accurately, adhering to the safety procedures to prevent product contamination, and observing sanitary regulations. A line operator must have comprehensive knowledge of the mechanical industry, as well as the ability to multi-task, especially on meeting deadlines and processing customers' orders.

These skill sets are where the common ground ends though. The responsibilities of a production line assembler are more likely to require skills like "assembly process," "ran," "machine operators," and "circuit boards." On the other hand, a job as a line operator requires skills like "mechanical troubleshooting," "preventative maintenance," "ppe," and "basic math." As you can see, what employees do in each career varies considerably.

Line operators earn the highest salaries when working in the manufacturing industry, with an average yearly salary of $37,379. On the other hand, production line assemblers are paid more in the automotive industry with an average salary of $31,294.The education levels that line operators earn slightly differ from production line assemblers. In particular, line operators are 0.5% more likely to graduate with a Master's Degree than a production line assembler. Additionally, they're 0.2% more likely to earn a Doctoral Degree.Production line assembler vs. Assembly line worker

Assembly line workers are factory or production floor employees who work on putting together company products. They are assigned to work on a specific part of the product. Once they are done, they should hand it over to the next person on the line. They ensure the quality of the product by doing their part consistently. They also manage the inventory of the features they handle. Assembly line workers should work conscientiously so that the assembly line will remain unbroken. They should be familiar with occupational safety and health practices to ensure that the production floor remains safe for all the workers.

In addition to the difference in salary, there are some other key differences worth noting. For example, production line assembler responsibilities are more likely to require skills like "safety standards," "assembly process," "ran," and "cnc." Meanwhile, an assembly line worker has duties that require skills in areas such as "assembly line production," "pallet jack," "hand-held tools," and "eye coordination." These differences highlight just how different the day-to-day in each role looks.

On average, assembly line workers earn a higher salary than production line assemblers. Some industries support higher salaries in each profession. Interestingly enough, assembly line workers earn the most pay in the technology industry with an average salary of $33,465. Whereas production line assemblers have higher pay in the automotive industry, with an average salary of $31,294.Average education levels between the two professions vary. Assembly line workers tend to reach similar levels of education than production line assemblers. In fact, they're 0.0% more likely to graduate with a Master's Degree and 0.2% more likely to earn a Doctoral Degree.Production line assembler vs. Assembler/team lead

An assembly inspector is primarily in charge of inspecting products, usually furniture and fixtures, to ensure compliance with production standards. Their responsibilities typically include examining surfaces to identify any dents or damages, conducting measurements and assessments, marking identified issues, reviewing documentation, and maintaining records, producing detailed reports for teams and managers. Moreover, as an assembly inspector, it is essential to lead and encourage staff to reach goals, all while implementing the company's production standards and policies.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a production line assembler is likely to be skilled in "ran," "machine operators," "power drills," and "ac," while a typical assembler/team lead is skilled in "continuous improvement," "assembly line," "lean manufacturing," and "production schedules."

When it comes to education, assembler/team leads tend to earn similar degree levels compared to production line assemblers. In fact, they're 1.9% more likely to earn a Master's Degree, and 0.1% more likely to graduate with a Doctoral Degree.Production line assembler vs. Assembly inspector

Types of production line assembler

Updated January 8, 2025