Automatically apply for jobs with Zippia

Upload your resume to get started.

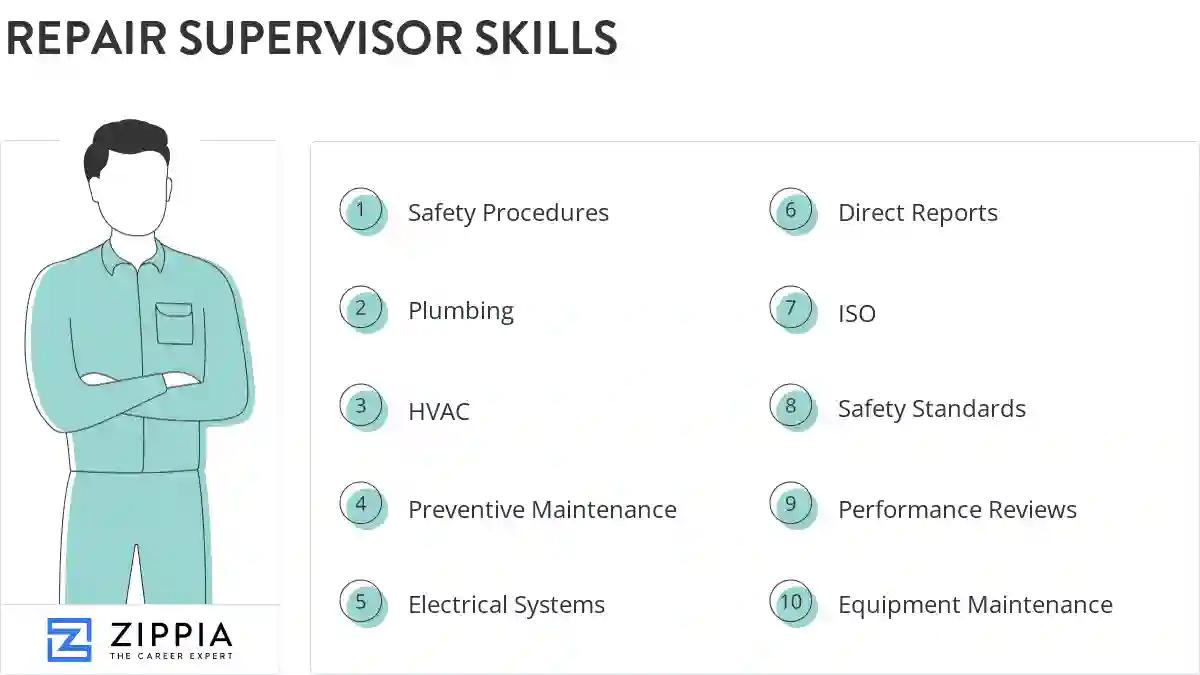

Repair supervisor skills for your resume and career

15 repair supervisor skills for your resume and career

1. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Facilitated a Business Continuity Team to create and maintain safety procedures for our locations.

- Created safety procedures and standard operations procedures.

2. Plumbing

- Facilitated and supplied residential and commercial construction/remodeling, property maintenance, carpentry, electrical, plumbing, roofing and painting.

- Direct Staff and Perform all phases of building Maintenance including Floor Maintenance, Painting, Plumbing, Electrical repair 115/270V

3. HVAC

- Created facility maps and building diagrams displaying underground utility locations and extensive HVAC distribution system.

- Maintained and serviced HVAC systems and refrigeration equipment.

4. Preventive Maintenance

- Perform routine preventive maintenance on both electric and battery operated equipment.

- Performed preventive maintenance and made repairs to Power Generation Equipment.

5. Electrical Systems

- Ensured proper maintenance procedures performed on AH-64A armament/avionics/electrical systems.

- Conducted inspections, troubleshooting, testing and repair of aircraft Avionics and Electrical Systems at unit and intermediate levels.

6. Direct Reports

- Mentor a staff of 14 direct reports to exceed metrics of Quality, First call resolution, and Transitional sales.

- Draft quarterly reviews for direct reports to be signed and documented to senior management.

Choose from 10+ customizable repair supervisor resume templates

Build a professional repair supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your repair supervisor resume.7. ISO

- Developed and maintained ISO documentation to ensure high quality repair.

- Participated in the implementation ISO 9001 certification.

8. Safety Standards

- Managed shop performance on KPI to ensure downtime and safety standards are met.

- Do weekly WISR reports for submission to Subway Inc.* Maintain safety standards for both my associates and the food we serve.

9. Performance Reviews

Performance reviews refer to the official evaluation of a worker's performance done by the manager. The evaluation then helps the superior identify the worker's strengths and weaknesses and offers valuable feedback to help him overcome his shortcomings. This assessment also helps a worker set a future goal for himself and identify ways to better his future performance. Performance Reviews may be done on a monthly or yearly basis, depending on the company.

- Managed daily workload assignments, organized and led monthly safety training, conducted Technician quality and performance reviews.

- Administered Technician workload assignments, quality measurements, performance reviews and time reporting.

10. Equipment Maintenance

Equipment maintenance is any process that includes the use of maintenance methods and procedures to keep the organization's equipment in good and reliable working condition. This may include routine maintenance as well as corrective repairs. The practice takes place in a variety of settings, including catering establishments, industrial factories, manufacturing facilities, hotels, etc.

- Performed final or quality control inspections of repaired equipment and kept detailed records of equipment maintenance.

- Visited customer locations and reviewed equipment maintenance information with customers.

11. Test Equipment

Test equipment is a mechanical tool or a device which is used create signals and gather response from an electronic device under test. It helps in detecting any faults in the device and it also proves the proper operation of the electronic device.

- Inspected, tested, and adjusted components to specific tolerances using special test equipment and computerized test controllers.

- Supervised the move and remodeling of the General Purpose Electronic Test Equipment (GPETE) Work Center.

12. Performance Evaluations

Performance evaluation is a formal and productive process to measure an employee's work and results based on their job responsibilities over a defined period of time and to properly measure an employee's contribution to the workforce and employers and achieve a high level of quality and quantity of work produced. The evaluation also helps employees provide information about deficiencies in job performance and the company's expectations for the future.

- Monitored student progress, counseled students, administered written evaluations, performance evaluations and graded the results.

- Perform regular performance evaluations on personnel under my direct supervision.

13. General Maintenance

General maintenance is the regular check-up and repairs of machinery, buildings, and other mechanical equipment. General maintenance is performed by repair workers who are skilled to handle the day-to-day defects produced in the machinery. General maintenance aims to make sure the items remain in the best operational conditions. Usually, a set of planned activities are performed regularly by an expert to monitor the maintenance.

- Perform general maintenance and basic repair of automotive fleet.

- General maintenance to full remodels on many different residential and commercial properties.

14. Technical Training

Technical Training refers to the act of teaching individuals the technical skills needed for various positions. This training may be on a form of software (though this doesn't include any coding technology), how to repair a piece of machinery, or how to operate a piece of machinery.

- Supervised the component and avionics repair technical training program.

- Carry out manufacture technical training.

15. Maintenance Operations

- Supervised maintenance operations of aircraft component repairs, planned workloads in terms of resources and facilities.

- Established work load and repair priorities, evaluated maintenance operations for compliance with technical manuals.

5 Repair Supervisor resume examples

Build a professional repair supervisor resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your repair supervisor resume.

What skills help Repair Supervisors find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of repair supervisor skills to add to your resume

The most important skills for a repair supervisor resume and required skills for a repair supervisor to have include:

- Safety Procedures

- Plumbing

- HVAC

- Preventive Maintenance

- Electrical Systems

- Direct Reports

- ISO

- Safety Standards

- Performance Reviews

- Equipment Maintenance

- Test Equipment

- Performance Evaluations

- General Maintenance

- Technical Training

- Maintenance Operations

- Inventory Control

- Safety Training

- Repair Procedures

- Production Control

- Technical Guidance

- Maintenance Procedures

- Repair Process

- Shop Operations

- Gross Profit

- Technical Manuals

- Depot

- Electronic Equipment

- Repair Facility

- Direct Support

- Hazardous Materials

- Hoists

- Ground Support Equipment

- Aircraft Maintenance

- Hazmat

- Performance Metrics

- Repair Operations

- Unscheduled Maintenance

- Professional Development

- Diagnostic Equipment

- Aircraft Components

- Bench Stock

- Technical Assistance

- Maintenance Management

- RMA

- Customer Issues

Updated January 8, 2025