Automatically apply for jobs with Zippia

Upload your resume to get started.

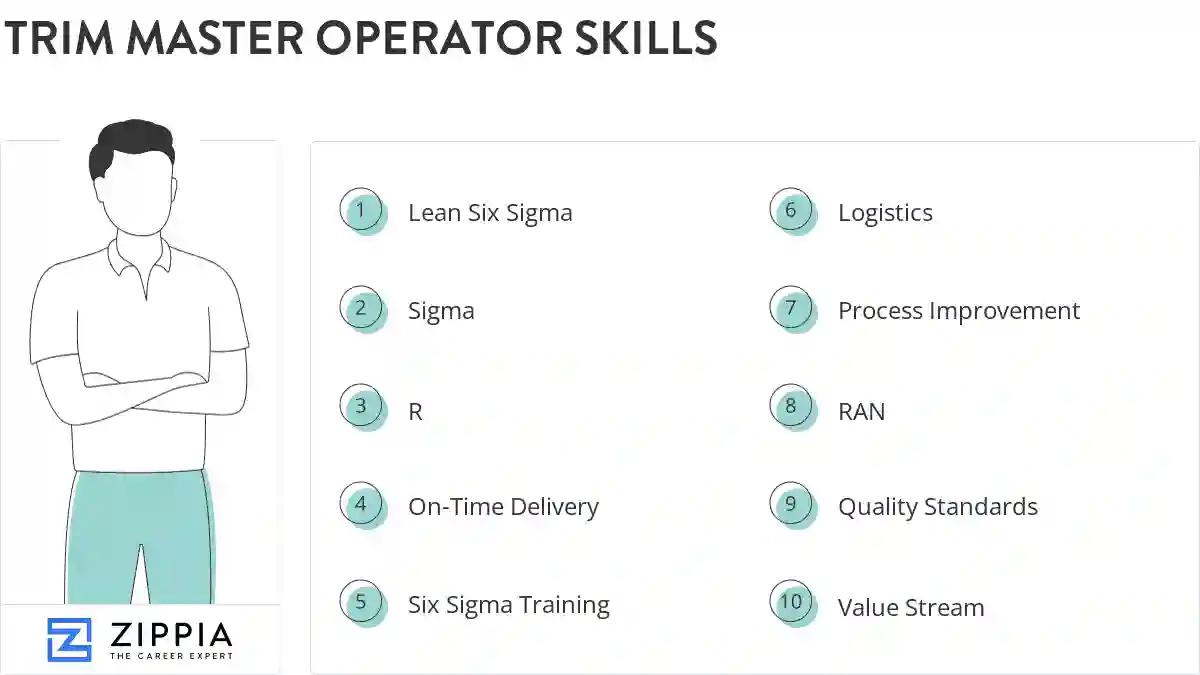

Trim master operator skills for your resume and career

14 trim master operator skills for your resume and career

1. Lean Six Sigma

- Trained employees from novice to executive level on lean six sigma.

2. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Provided company wide strategic guidance on corporate six sigma strategies and deployment to European parent company Operational Excellence Divisions.

- Charged with driving culture change at all sites through the application of Lean/Six Sigma methodology.

3. R

R is a free software environment and a language used by programmers for statistical computing. The R programming language is famously used for data analysis by data scientists.

- Developed an R package to identify enforcement trends for DoL agencies using PCA.

4. On-Time Delivery

On-Time Delivery, or OTD, is a metric that measures the rate at which finished goods and deliveries are completed on time. This rate is measured by the overall number of units shipped within a specified time frame agreed upon by the consumer and supplier. On-Time Delivery allows suppliers' compliance with delivery deadlines, and hence their consistency, to be assessed using a continuous and collaborative development approach.

- Ensured the establishment of manufacturing processes, procedures & controls to ensure On-time delivery of defect free products.

- Ensured on-time delivery of client projects using company van.

5. Six Sigma Training

- Led all Six Sigma-related business initiatives, including At-the-Customer-For-the-Customer strategy.

6. Logistics

Logistics is a complete organization and implementation of a problem. Logistics are often considered in a complex business operation, as some works need detailed plannings. Logistics are also used in military action.

- Handled weights & balances for cargo aircrafts as well as shipment logistics via commercial airlines & ground services.

- Conducted Transportation Planning, Transportation Procurement, Route Planning, Transportation Management, asset visibility and tracking, shipping and logistics.

7. Process Improvement

- Partnered with senior level functional leaders and global management staff to assess current processes and identify process improvement opportunities.

- Led internal crisis management activities with a record of providing quick process improvement support.

8. RAN

RAN stands for "revenue anticipation note," which refers to a practice where an organization (often the government) borrows money to support a specific project. When these funds are then repaid, the money given to the lenders comes from the profits generated by the business originally funded.

- Treated wood & operated lifts* Ran boilers through computer data system & maintenance on the boilers, kilns, etc.

- Completed sales of single tickets and subscriptions and ran the will-call line before show times.

9. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Operated machines effectively and safely according to ensure quality standards.

- Maintain production deadlines, assure quality standards throughout runs.

10. Value Stream

A value stream applies to any of the phases or stages that a buyer has the willingness to pay to transport a product or service across the main flows needed to manufacture the product or service.

- Process Optimization: Time Studies and establishment of Std Work for Door Value Stream.

11. Assembly Line

Assembly line is a process used in industries to ensure the production of products in a cost effective manner by dividing up the responsibilities of each labor. Assembly lines enabled industries to hire more workers, therefore providing more employment opportunities to labors. This is possible because in this process the burden of all the tasks related to production are not laid on a single person, they are divided into small baby steps for each labor.

- Started out as a manual packer on an assembly line.

- Earned recognition for producing equally impressive results both independently and as a team member within assembly line setting.

12. HR

HR stands for human resources and is used to describe the set of people who work for a company or an organization. HR responsibilities revolve around updating employee records and carrying out management processes like planning, recruitment, evaluation, and selection processes. HR is a key contributor to any company or organization's growth as they are in charge of hiring the right employees, processing payrolls, conducting disciplinary actions, etc.

- Run various HR and Payroll reports and manipulate extensively as needed utilizing Great Plains.

- Organize HR Operations team with tasks assigned.

13. Extrusion

- Set up/ operator Extrusion Machine Record keeping of processed Resin

- Moimted die to extrusion machine, adjusted heat profile and feed rate to start machine.

14. PLC

- Watched over and maintained PLC systems to stay within proper parameters of chemical movement and scrubbers.

- Background and understanding of PLC Systems and the ability to work within a team environment.

What skills help Trim Master Operators find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of trim master operator skills to add to your resume

The most important skills for a trim master operator resume and required skills for a trim master operator to have include:

- Lean Six Sigma

- Sigma

- R

- On-Time Delivery

- Six Sigma Training

- Logistics

- Process Improvement

- RAN

- Quality Standards

- Value Stream

- Assembly Line

- HR

- Extrusion

- PLC

Updated January 8, 2025