Automatically apply for jobs with Zippia

Upload your resume to get started.

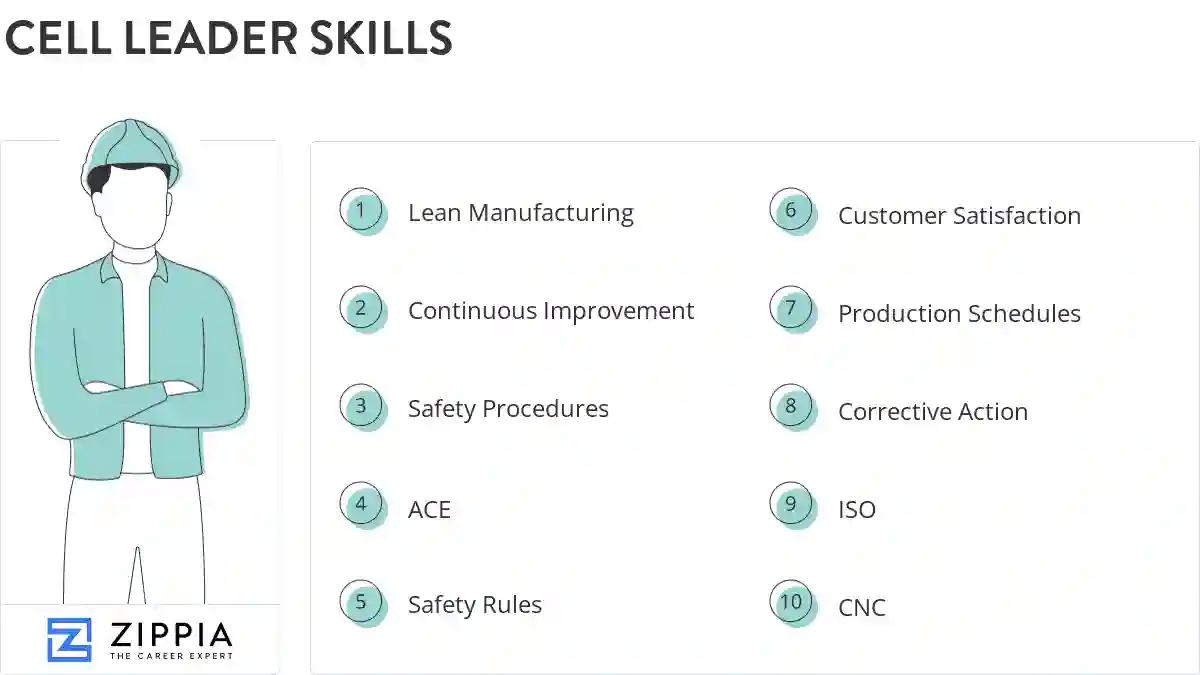

Cell leader skills for your resume and career

15 cell leader skills for your resume and career

1. Lean Manufacturing

- Operated equipment throughout manufacturing process while providing operational leadership and training in a lean manufacturing, continuous improvement environment.

- Implemented Lean Manufacturing principles to increase machining capacity and On Time Delivery.

2. Continuous Improvement

Continuous improvement is an ongoing process of improvement of products, services, and processes with the help of innovative ideas. It is an organized approach that helps an organization to find its weaknesses and improve them.

- Acquired Secret Government Clearance and assisted in controlling cost on our team through several continuous improvement initiatives.

- Implement continuous improvement plans to monitor efficiency, time management of completion and accuracy of job orders.

3. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Assist in the training of employees in company values and work related training including Safety procedures.

- Trained employees on work and safety procedures.

4. ACE

- Provided a leading role in achieving Ace Gold level for the QEC cell.

- Achieved and retained ACE Silver status of Cell.

5. Safety Rules

Principles or regulations that ensure the protection of people, objects, or the environment are called safety rules. These rules can be governing actions, devices, or procedures that help in minimizing the risks of loss, injury, or damage.

- Acted as liaison with state and local agencies regarding compliance to all safety rules and regulations.

- Comply with all safety rules and use any and all personal protection equipment as required.

6. Customer Satisfaction

- Promoted twice during tenure and consistently achieved all assigned objectives for production, training and customer satisfaction.

- Demonstrated ability to establish priorities and ensure customer satisfaction as defined by demand.

Choose from 10+ customizable cell leader resume templates

Build a professional cell leader resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your cell leader resume.7. Production Schedules

The project plan of a film or a documentary that highlights how a production budget will be spent over a given period until its completion is called a production schedule. The scheduling process starts with writing and analyzing the script, which is then broken down to determine and allocate the budget for each scene. The production schedule also includes several elements of the film including; cast actors, special effects, wardrobe, special equipment, stunts, extras, silent bits, production equipment, and many others.

- Prepare necessary documentation for daily production schedule.

- Maintained the daily production schedule as well as the overall safety of crew.

8. Corrective Action

- Implement appropriate relationship development to ensure strong communication flow to enable immediate awareness of deviations to plan and corrective actions.

- Formulated discrepancies reports on defective parts or materials, while subsequently generating and implementing corrective action plans.

9. ISO

- Conducted multiple Threat Vulnerability Assessments throughout central and western Africa ISO of operational facilities.

- Ensured compliance with FAA regulations, established policies and procedures, ISO 9001, Engine manual and customer requirements.

10. CNC

CNC stands for Computer Numerical Control. It is a subtractive manufacturing technique that usually uses computerized controls and machine tools to strip layers of material from a stock piece.

- Trained team members on required programming steps and support functions -- CNC wire EDM, surface grinding, and brazing.

- Help train coworkers to set up and run CNC turret press, CNC Press brakes (hydraulic and manual).

11. Performance Reviews

Performance reviews refer to the official evaluation of a worker's performance done by the manager. The evaluation then helps the superior identify the worker's strengths and weaknesses and offers valuable feedback to help him overcome his shortcomings. This assessment also helps a worker set a future goal for himself and identify ways to better his future performance. Performance Reviews may be done on a monthly or yearly basis, depending on the company.

- Performed semi-annual and annual performance reviews for associates.

- Completed performance reviews for operators.

12. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Consulted/Co-developed operating procedure for long standing ADE measuring system that enabled faster reads and higher quality standards.

- Inspected parts to required tolerances ensuring production and quality standards.

13. Leadership

- Trained new technicians on precision manufacturing processes and supervisors in leadership strategies.

- Presented monthly to business leadership.

14. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Performed JIT and Kanban functions along with Six Sigma techniques.

- Led analysis and identification of process bottlenecks and redundancies and used Six Sigma principles extensively in streamlining processes.

15. Kaizen

Kaizen is a Japanese term derived from the words "kai-" which means "Change" and "zen" for good. In short, Kaizen means "change for the better," or it could also mean "continuous improvement." It is a term used for the process that continuously improves all employees. Kaizen believes in the improvement in productivity in a gradual and methodological approach. This improvement could happen by making the workplace more efficient and effective by improving team atmosphere, making the job less tiring and fulfilling and safer for the employees. Members of a company are expected to suggest an improvement when they encounter a problem.

- Monitored safety, quality, cost, and productivity, with Kaizen activities for assigned areas of production.

- Lead and participate on Kaizen events aimed at cycle time reduction and part quality improvement.

5 Cell Leader resume examples

Build a professional cell leader resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your cell leader resume.

What skills help Cell Leaders find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of cell leader skills to add to your resume

The most important skills for a cell leader resume and required skills for a cell leader to have include:

- Lean Manufacturing

- Continuous Improvement

- Safety Procedures

- ACE

- Safety Rules

- Customer Satisfaction

- Production Schedules

- Corrective Action

- ISO

- CNC

- Performance Reviews

- Quality Standards

- Leadership

- Sigma

- Kaizen

- Production Cell

- On-Time Delivery

- MRP

- OTD

- Quality Checks

- Kanban

- Safety Policies

- GMP

- Quality Products

- Assembly Line

- Quality Issues

- Process Improvement

- Production Floor

- TPM

- FDA

- Quality Inspection

- Troubleshoot

- Machine Operators

- Production Equipment

- SPC

- Production Reports

- QA

- Customer Orders

- Direct Reports

- Extrusion

- Customer Demand

- WIP

- Production Lines

- FANUC

- Jigs

- EDM

- Inventory Control

- Customer Specifications

- Process Control

Updated January 8, 2025