Automatically apply for jobs with Zippia

Upload your resume to get started.

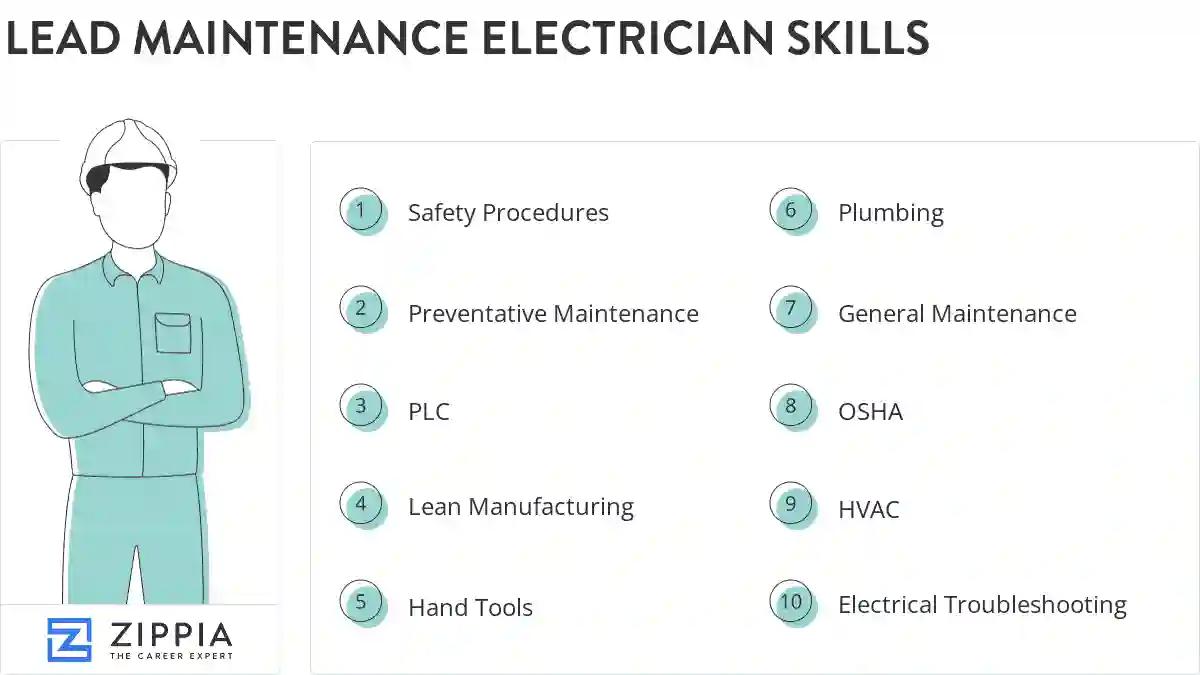

Lead maintenance electrician skills for your resume and career

15 lead maintenance electrician skills for your resume and career

1. Safety Procedures

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

- Trained fellow electricians in PLC and HMI programming, troubleshooting techniques, and safety procedures.

- Train on the proper operation and safety procedures for equipment.

2. Preventative Maintenance

- Recruited to provide high-level electrical system engineering to support installation and on-site preventative maintenance of equipment and machinery.

- Prioritize and perform daily scheduled preventative maintenance on production packaging equipment.

3. PLC

- Diagnosed equipment problems using a laptop computer and interface through a PLC.

- Trouble shooting and programming with multiple PLC based manufacturers.

4. Lean Manufacturing

- Supervised Electrical and Mechanical maintenance technicians in the repair of high speed making and packing equipment in a Lean Manufacturing operation.

- Participated in process improvement initiatives, using innovative tools such as Lean manufacturing, Six Sigma, and equipment optimization.

5. Hand Tools

- Replace or repair worn, defective, or damages components, using hand tools, gauges, and testing equipment.

- Repair, install, replace and test electrical circuits, equipment and appliances using necessary hand tools and testing instruments.

6. Plumbing

- Work included basic carpentry, plumbing, re-fit & start-up procedures, structures, parking lots and landscaping maintenance and repairs.

- Assisted with boiler maintenance, repair and replacement, plumbing, drywall, painting, Compressor- maintenance, and repair.

Choose from 10+ customizable lead maintenance electrician resume templates

Build a professional lead maintenance electrician resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your lead maintenance electrician resume.7. General Maintenance

General maintenance is the regular check-up and repairs of machinery, buildings, and other mechanical equipment. General maintenance is performed by repair workers who are skilled to handle the day-to-day defects produced in the machinery. General maintenance aims to make sure the items remain in the best operational conditions. Usually, a set of planned activities are performed regularly by an expert to monitor the maintenance.

- Performed daily, weekly and monthly general maintenance for overall plant operations And trouble shooting tasks to prevent system breakdown.

- Provided general maintenance to all manufacturing and operating systems and implemented upgrades and improvements to systems and processes.

8. OSHA

- Identified and repaired electrical issues related to various machines, ensuring compliance with all OSHA / industry codes.

- Train and insure Lock out and tag out OSHA procedures are followed 4.

9. HVAC

- Monitor Dual Stage Ammonia Refrigeration Systems, HVAC Systems, & Boilers.

- Worked with HVAC staff on new equipment installs as well as replacement.

10. Electrical Troubleshooting

- Verified proper operation and performed electrical troubleshooting of new automation equipment.

- Field technician in basic electrical troubleshooting and repair.

11. Mechanical Equipment

Mechanical equipment is a term referring to the machinery which have been created and gathered for the purpose of fulfilling one or more functions and consisting of, most often, multiple components.

- Used diagnostic equipment and schematics to troubleshoot and repair complex electronic and mechanical equipment.

- Repair all plant electrical and mechanical equipment and services including all overhead crane repair and pm.

12. Production Equipment

Production equipment in limited terms is used to define any type of machinery or equipment used in the production of a video or film. Basic production equipment includes a camera, tripod, lighting kit, camera light, short term microphone, light reflector, boom pole, shock mount, audio cables, wireless microphone, headphones, portable digital audio recorder, camera lenses, extra batteries, external hard drive, and DSLR shoulder mount rig.

- Updated operations manager and production department supervisors on down time and other production equipment issues at daily production meeting.

- Maintained and repaired all production equipment and related gear, including computerized DC power drives/motors, and chilled-water systems.

13. Test Equipment

Test equipment is a mechanical tool or a device which is used create signals and gather response from an electronic device under test. It helps in detecting any faults in the device and it also proves the proper operation of the electronic device.

- Diagnose faults or malfunctions to determine required repairs, using engine diagnostic equipment such as computerized test equipment and calibration devices.

- Measured and analyzed Capacitors capacitance and dissipation factor with test equipment such as LCR Meter.

14. Ac

AC (Alternating Current) is the electric current that periodically changes its polarity and magnitude. Most devices, which are connected to the electrical grid directly, operate on AC. Electrical outlets in commercial areas and homes also supply electrical current.

AC may also refer to Air Conditioning as it relates to working to install duct work and air conditing units as part of an HVAC system.

- Plant used many types of drives including Frequency, DC, Brushless DC and AC throughout.

- Install and troubleshoot electric motor controls, starters, relay switches (480 volt AC 3 phase).

15. Dc

- Head Electrician when events are hosted concerning DC United Soccer Team and Events DC.

- Represented company in Washington, DC at the annual ESOP conference.

5 Lead Maintenance Electrician resume examples

Build a professional lead maintenance electrician resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your lead maintenance electrician resume.

What skills help Lead Maintenance Electricians find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

List of lead maintenance electrician skills to add to your resume

The most important skills for a lead maintenance electrician resume and required skills for a lead maintenance electrician to have include:

- Safety Procedures

- Preventative Maintenance

- PLC

- Lean Manufacturing

- Hand Tools

- Plumbing

- General Maintenance

- OSHA

- HVAC

- Electrical Troubleshooting

- Mechanical Equipment

- Production Equipment

- Test Equipment

- Ac

- Dc

- Mechanical Problems

- CMMS

- Equipment Maintenance

- Electrical Systems

- Control Systems

- Building Maintenance

- Maintenance Program

- Hydraulic Systems

- Maintenance Procedures

- Production Machines

- Plant Maintenance

- Electrical Problems

- CNC

- Production Lines

- VFD

- Hoists

- Mechanical Troubleshooting

- Electrical Equipment

- Electronic Equipment

- FANUC

- HMI

- Gearboxes

- Maintenance Training

- Windows

- Blowers

- Electrical Components

- OEM

- Water Systems

- Electrical Issues

Updated January 8, 2025