Automatically apply for jobs with Zippia

Upload your resume to get started.

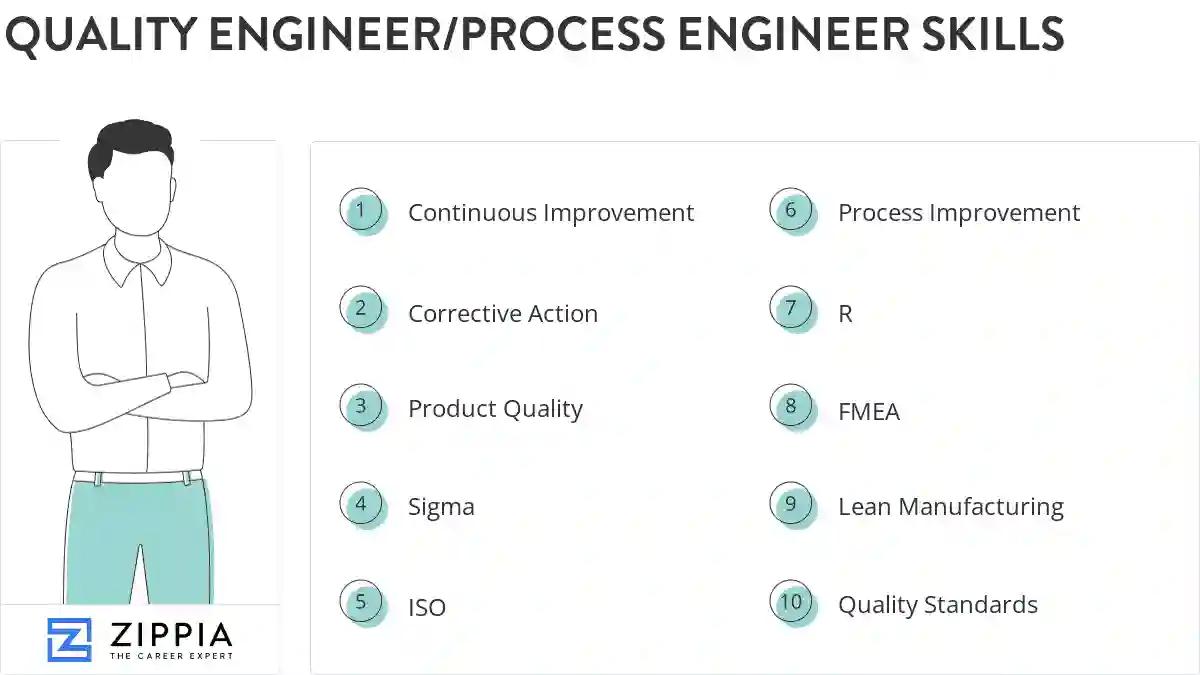

Quality engineer/process engineer skills for your resume and career

15 quality engineer/process engineer skills for your resume and career

1. Continuous Improvement

Continuous improvement is an ongoing process of improvement of products, services, and processes with the help of innovative ideas. It is an organized approach that helps an organization to find its weaknesses and improve them.

- Led Continuous Improvement Teams in Lean Manufacturing and Six Sigma principle-based efforts in eliminating quality problems and in improving efficiency.

- Provide support to manufacturing for continuous improvements by analyzing, identifying and implementing projects to reduce PPM levels.

2. Corrective Action

- Provide material review dispositions for non-conforming material or procedures, identifying non-conformance trends and evaluating the effectiveness of corrective actions taken.

- Conducted process flow root cause analysis, interpreted accumulated data, engaged corrective actions that eliminated repeated process cells.

3. Product Quality

Product quality is the basic element of a business. It means to add features in a product or service in such a way that it meets the needs and wants of the customers. Enhancing the product quality also means improve the goods from any existing defects to ensure customer satisfaction.

- Identified potential product quality trends.

- Maintained product quality levels and plant operational efficiency for one of TVA's coal processing plants outputting 24,000 tons of coal/day.

4. Sigma

In Greek alphabets, sigma is the 18th letter that means "to sum up". In statistics, the lower case symbol of sigma is the unit of measurement for standard deviation which is used to assess the variability in a given set of data. While the upper case symbol is for summation notation means to add up all the given numbers in the data set.

- Required statistical analysis and meeting minimum quality requirements per the Six Sigma Quality system.

- Designed and implemented Six Sigma continuous process improvement projects on production processes.

5. ISO

- Measure and control quality in production process by establishing, implementing and maintaining quality management system.ISO 9001:2015 internal Auditor

- Helped secure ISO certification and ensured ongoing agency compliance for the Manufacturing & Process Engineering Departments.

6. Process Improvement

- Performed statistical analysis on multivariate quality control data and derived insights in order to provide recommendations for continuous process improvement.

- Evaluated with engineers the identification of compromised technical requirements, implemented best business practices, and proposed process improvements.

Choose from 10+ customizable quality engineer/process engineer resume templates

Build a professional quality engineer/process engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your quality engineer/process engineer resume.7. R

R is a free software environment and a language used by programmers for statistical computing. The R programming language is famously used for data analysis by data scientists.

- Participated in multiple model year changes and launches of the Mercedes M, R and GL Class Vehicles.

- Full capabilities studies, Gage R and R, Kappa Studies and Olympus Magma Mic dimensional layouts.

8. FMEA

- Created FMEA's for Vacuum Furnaces and air furnaces.

- Manage and review Process FMEA.

9. Lean Manufacturing

- Eliminated waste by using 5-S, Poke-Yoke and Lean manufacturing techniques in candy line.

- Implemented guidelines for Lean Manufacturing and 5-S at new facility.

10. Quality Standards

Quality standards are a specific level of standards of products that are set by the companies for the customers that have to be met and maintained throughout the process until the time of delivery. Quality standards are information that includes the customer's requirements, guidelines, and characteristics for the needed final product or service.

- Developed quality standards and implemented change as necessary.

- Generated work instructions for quality standards.

11. Lean Six Sigma

- Maintained daily planet operation, performed and analyze lean six sigma methodology.

- Supervised and coordinated Lean Six Sigma Quality workshops.

12. Quality Procedures

Quality procedures are at the core of the quality management system. These procedures determine processes that ensure everything is performed according to the standard requirements. Quality procedures consist of quality manual, internal audits performance, guidelines for control of documents, records, nonconformity, integration, corrective and preventive action.

- Identified and implemented quality procedures and standards for quality auditors and production associates to follow.

- Coordinated and implemented government quality procedures and activities in the facility.

13. Management System

A management system is a set of policies, processes, and procedures taken by an organization or a business to ensure it can fulfill its tasks and achieve its objectives. A management system makes sure that the company excels financially and improves the user experience. The management system also takes care of the worker's and employees' needs and manages their workload and oversees their performance. Apart from interior matters of the company, a management system also deals with exterior matters like legislations, tax matters, and law issues.

- Create and implement Quality Management systems procedures and work instructions for customer compliance.

- Established and organized change management system to document process engineering changes.

14. Statistical Analysis

- Led team to develop and implement system for statistical analysis of product conformance to requirements.

- Monitored raw material quality between bakeries and supplier companies using statistical analysis.

15. Data Analysis

- Perform statistical data analysis including designed experiments, process capability, and statistical process control.

- Directed activities of Interns working on material replacement and data analysis projects.

5 Quality Engineer/Process Engineer resume examples

Build a professional quality engineer/process engineer resume in minutes. Browse through our resume examples to identify the best way to word your resume. Then choose from 5+ resume templates to create your quality engineer/process engineer resume.

What skills help Quality Engineer/Process Engineers find jobs?

Tell us what job you are looking for, we’ll show you what skills employers want.

What skills stand out on quality engineer/process engineer resumes?

Dr. Maria Benavides Ph.D.

Associate Professor, Chemistry Program Coordinator, Assistant Chair, University of Houston - Downtown

What soft skills should all quality engineer/process engineers possess?

Dr. David Grewell Ph.D.

Department Chair and Professor, North Dakota State University

What hard/technical skills are most important for quality engineer/process engineers?

Dr. David Grewell Ph.D.

Department Chair and Professor, North Dakota State University

What quality engineer/process engineer skills would you recommend for someone trying to advance their career?

Professor and Chairman, California State Polytechnic University, Pomona

What type of skills will young quality engineer/process engineers need?

Distinguished Professor of Materials Science and Engineering, Director Advanced Casting Research Center (ACRC), University of California

Those graduates who will succeed and lead will have:

an understanding of the human dimension;

the ability to harvest the data revolution;

skills in line with the Industry 4.0 pathways; and

commercial and business acumen.

What technical skills for a quality engineer/process engineer stand out to employers?

Adjunct Instructor, Clarkson University

Respectfully, today's graduates do not understand that being able to text and use social media does not prepare them for "real" computer skills. Many students that I have in high school and in college do not have proper writing skills, document formatting skills, or document management skills to know how to save documents properly and where to save to.

List of quality engineer/process engineer skills to add to your resume

The most important skills for a quality engineer/process engineer resume and required skills for a quality engineer/process engineer to have include:

- Continuous Improvement

- Corrective Action

- Product Quality

- Sigma

- ISO

- Process Improvement

- R

- FMEA

- Lean Manufacturing

- Quality Standards

- Lean Six Sigma

- Quality Procedures

- Management System

- Statistical Analysis

- Data Analysis

- Quality Issues

- Quality System

- Statistical Process Control

- Process Engineering

- Process Flow

- Supplier Quality

- FDA

- PPAP

- Customer Complaints

- Process Audits

- QA

- Capability Studies

- Preventive Actions

- Kaizen

- GMP

- Technical Support

- Data Collection

- Internal Audit

- Minitab

- Customer Satisfaction

- QMS

- Process Changes

- Production Processes

- DOE

- Measurement System Analysis

- Failure Analysis

- DMAIC

- CMM

- Value Stream

- QC

- Production Lines

- APQP

- OQ

- Cost Savings

- ERP

Updated January 8, 2025