What does a supply chain development manager do?

Supply Chain Development Managers are responsible for coordinating overall logistics with the intent to minimize cost and maximize the efficiency of its supply chain. They are responsible for implementing supply chain process improvements, forecasting demand and supply to make sure supplies are readily available, negotiating terms with vendors and suppliers, and developing performance metrics to measure product cost and quality. Other duties include designing plant warehouse strategies, reviewing the manufacturing ability of vendors, managing staffing levels and equipment needs as well as creating procedures for cross-team supply chain coordination such as between the sales, marketing, and production departments.

Supply chain development manager responsibilities

Here are examples of responsibilities from real supply chain development manager resumes:

- Manage SD quality personnel involve with all supplier submissions for PPAP, IMDS and SOC4.

- Manage the scoping, assessment, and delivery of solutions that addressed client's business KPI's.

- Facilitate cross functional sourcing teams for strategically manage commodities, in support of optimizing the supply base.

- Negotiate, manage and execute RFQ s and quotes for spot buys, formal bids and long term agreements.

- Manage supplier risk and look for improvements by offering alternate suppliers for sole source components while considering the FDA requirements.

- Manage inventory accuracy across all warehousing and manufacturing locations, and maintaining all material master information within the ERP system.

- Coordinate WebUI and EDI vendor on-boarding.

- Analyze and adjust ERP parameters to aid in inventory reduction objectives.

- Review and approve all vendor ppap submissions for new product and engineering changes.

- Prepare and present detailed WBR/MBR metrics and KPI's to various internal/external audiences.

- Develop BOM structure for various scopes of supply (in-house fabrication / out-source fabrication / mix projects).

- Promote to first-of-kind position as logistics liaison for largest grocery customer.

- Manage inventory accuracy across all warehousing and manufacturing locations, and maintaining all material master information within the ERP system.

- Analyze partner capabilities for enrollment into EDI testing environment.

Supply chain development manager skills and personality traits

We calculated that 23% of Supply Chain Development Managers are proficient in Supply Chain, Chain Processes, and Logistics.

We break down the percentage of Supply Chain Development Managers that have these skills listed on their resume here:

- Supply Chain, 23%

Leveraged relationships with internal and external category management, supply chain management, logistics and planning to execute Go-To-Market strategies.

- Chain Processes, 11%

Led development and implementation of new product introduction (NPI) and supply chain processes to integrate multiple divisions.

- Logistics, 10%

Lean Leader - Led productivity improvements and Lean Six Sigma implementation at Charlotte Distribution and Logistics facility.

- Chain Management, 9%

Analyze and streamline business processes guiding the supply chain management cycle implementing corrective actions to ensure alignment with operational procedures.

- Product Development, 9%

Coordinate Test and Product Validation schedules in conjunction with Product Development and Program Management teams.

- Project Management, 8%

Project Management accomplishments: o Tax Audit review of major vendor contracts, in conjunction with Tax/Legal departments and Internal Audit.

Common skills that a supply chain development manager uses to do their job include "supply chain," "chain processes," and "logistics." You can find details on the most important supply chain development manager responsibilities below.

See the full list of supply chain development manager skills

The three companies that hire the most supply chain development managers are:

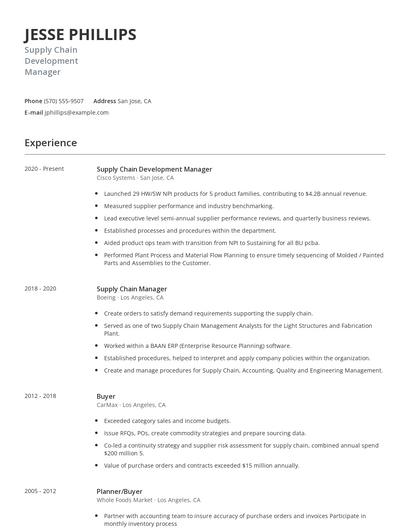

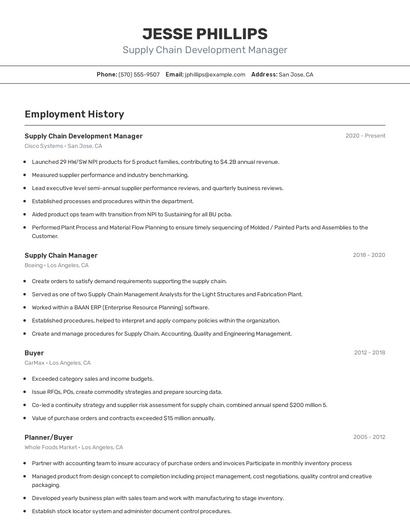

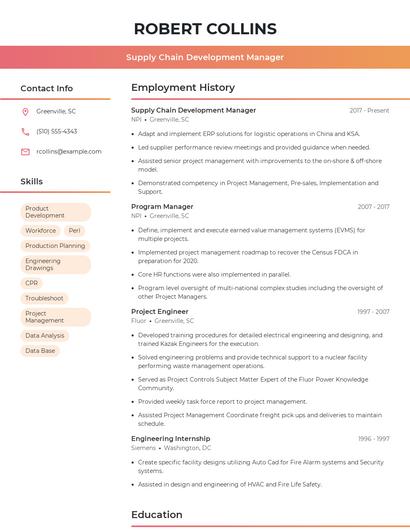

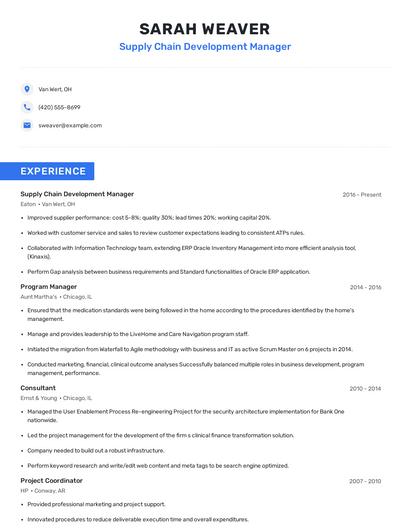

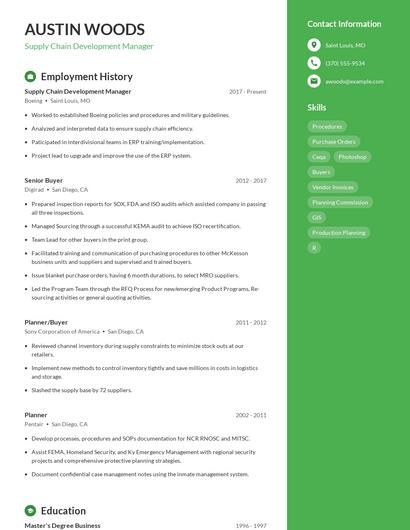

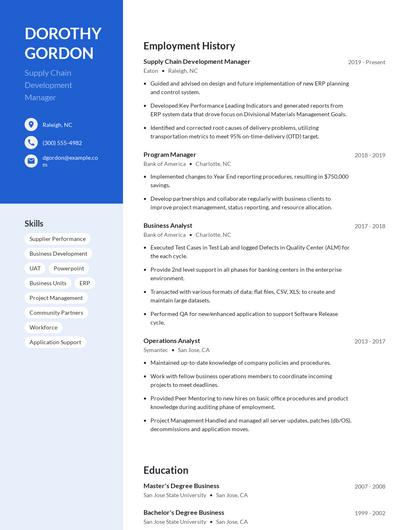

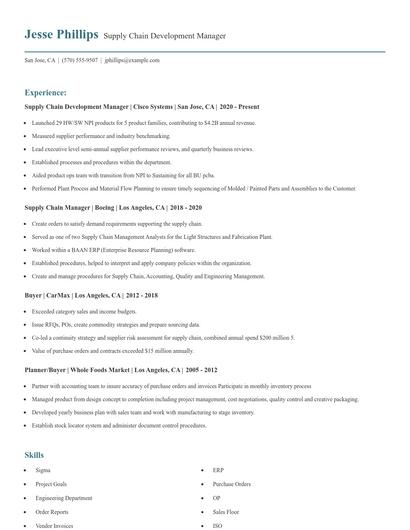

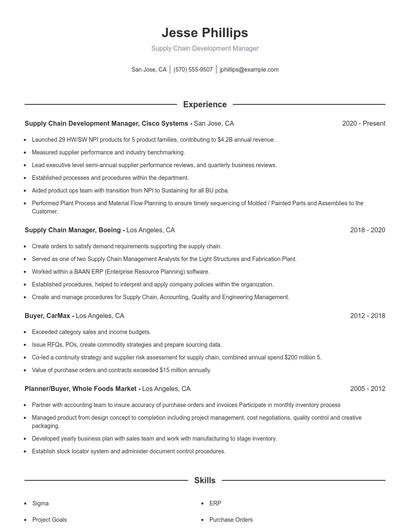

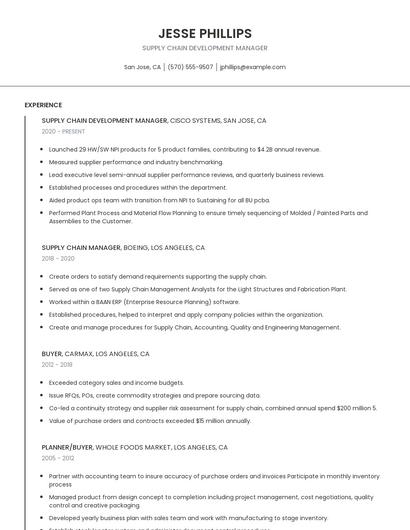

Choose from 10+ customizable supply chain development manager resume templates

Build a professional supply chain development manager resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your supply chain development manager resume.Compare different supply chain development managers

Supply chain development manager vs. Inventory management specialist

An inventory management specialist is responsible for maintaining the adequacy of stock supplies to support customers' needs. Inventory management specialists help develop inventory processes and strategies to keep the supplies organized and free of any defects while on storage. They also monitor inventory costs and process orders through various software tools, requiring them to have a working knowledge of computer systems and the ability to operate warehouse equipment and machinery on moving merchandise around the warehouse.

While similarities exist, there are also some differences between supply chain development managers and inventory management specialist. For instance, supply chain development manager responsibilities require skills such as "supply chain," "chain processes," "logistics," and "chain management." Whereas a inventory management specialist is skilled in "customer service," "inventory management system," "purchase orders," and "sales floor." This is part of what separates the two careers.

Inventory management specialists really shine in the government industry with an average salary of $65,378. Comparatively, supply chain development managers tend to make the most money in the automotive industry with an average salary of $106,285.On average, inventory management specialists reach lower levels of education than supply chain development managers. Inventory management specialists are 14.9% less likely to earn a Master's Degree and 0.7% less likely to graduate with a Doctoral Degree.Supply chain development manager vs. Director of supply chain operations

A director of supply chain operations is in charge of spearheading the manufacturing processes in a company, ensuring efficiency and smooth workflow. Their responsibilities revolve around devising strategies to improve procedures and systems, setting goals and objectives, managing the workforce, liaising with key distributors and clients, and monitoring the progress of every function. Furthermore, as a director, it is essential to lead and encourage the workforce to reach goals and optimal performance, all while implementing the company's policies and regulations.

While some skills are similar in these professions, other skills aren't so similar. For example, resumes show us that supply chain development manager responsibilities requires skills like "chain processes," "logistics," "product development," and "regression." But a director of supply chain operations might use other skills in their typical duties, such as, "customer service," "process improvement," "demand planning," and "kpis."

Directors of supply chain operations may earn a higher salary than supply chain development managers, but directors of supply chain operations earn the most pay in the pharmaceutical industry with an average salary of $117,181. On the other hand, supply chain development managers receive higher pay in the automotive industry, where they earn an average salary of $106,285.In general, directors of supply chain operations achieve similar levels of education than supply chain development managers. They're 0.3% more likely to obtain a Master's Degree while being 0.7% less likely to earn a Doctoral Degree.Supply chain development manager vs. Inventory control manager

An inventory control manager is an individual who is responsible for directing all tasks related to inventory management of a company. They manage the allocation of materials, supplies, and finished goods as well as design strategies to minimize the cost or time to move goods. They are required to lead a team of storage or warehouse personnel to help them with the actual inventory count. Inventory control managers must also develop a business relationship with their suppliers or vendors.

The required skills of the two careers differ considerably. For example, supply chain development managers are more likely to have skills like "supply chain," "chain processes," "chain management," and "product development." But a inventory control manager is more likely to have skills like "inventory control procedures," "sales floor," "customer service," and "team work."

Inventory control managers make a very good living in the retail industry with an average annual salary of $59,685. On the other hand, supply chain development managers are paid the highest salary in the automotive industry, with average annual pay of $106,285.When it comes to education, inventory control managers tend to earn lower degree levels compared to supply chain development managers. In fact, they're 13.3% less likely to earn a Master's Degree, and 0.7% less likely to graduate with a Doctoral Degree.Supply chain development manager vs. Senior supply chain analyst

Senior Supply Chain Analysts are employees who oversee the supply chain system of the company. They have in-depth knowledge of the company's supply chain system, and they ensure that all processes in the system are properly followed. They keep themselves updated on current trends and continuously find ways to enhance the existing supply chain processes of the company. Senior Supply Chain analysts study company data and anticipate challenges that the company may meet. They address challenges related to the supply chain. They also recommend solutions to senior management. Senior Supply Chain analysts may also take on a supervisory role, managing and coaching more junior team members.

Types of supply chain development manager

Updated January 8, 2025