What does a process safety engineer do?

A process safety engineer is responsible for conducting quality check procedures for the operational processes of the manufacturing and construction industries. Process safety engineers analyze practices to ensure that the methodologies adhere to safety standards and state regulations. They also inspect the tools and materials used, the budget needed for production, and timetables to strategize efficient ways in minimizing costs and risks. A process safety engineer records the process findings and suggests technical solutions to maximize productivity.

Process safety engineer responsibilities

Here are examples of responsibilities from real process safety engineer resumes:

- Manage chemical process operations risk and EHS programs.

- Lead troubleshooting of PLC, electrical, pneumatics, and hydraulic equipment.

- Manage hazardous and special waste programs and profiles including audits/inspections, vendor compliance, documentation and recordkeeping.

- Participate as an active member in the review of documentation and citation items relate to the OSHA PSM regulation.

- Progress projects relate to environmental, health, and safety (EHS).

- Collect thorough and detail data and write CB reports using the data and analysis.

- Facilitate compliance with EPA and OSHA regulations governing accidental releases of extremely hazardous materials.

- Develop and coordinate departmental ergonomics project that contribute to equipment design changes, business system modifications and revise employee work habits.

- Coordinate and participate in identifying and evaluating HSE hazards/risks and recommend measures to reduce them.

Process safety engineer skills and personality traits

We calculated that 10% of Process Safety Engineers are proficient in Safety Management, OSHA, and Risk Management. They’re also known for soft skills such as Communication skills, Creativity, and Problem-solving skills.

We break down the percentage of Process Safety Engineers that have these skills listed on their resume here:

- Safety Management, 10%

Develop Process Safety Management programs, standards, and procedures to ensure regulatory compliance with domestic and international regulatory agencies.

- OSHA, 8%

Participated as an active member in the review of documentation and citation items related to the OSHA PSM regulation.

- Risk Management, 6%

Review and maintain Risk Management Program, Contingency Plan, Emergency preparedness Plan & Spill prevention Process Control (SPPC).

- PHA, 6%

Perform PHA (Process Hazard Analysis) Study for natural gas assets and facilities, e.g.

- EHS, 5%

Progressed projects related to environmental, health, and safety (EHS).

- Mechanical Integrity, 5%

Initiated and led project to reprogram malfunctioning Microsoft Access database that tracked Mechanical Integrity inspections for Process Safety program.

Most process safety engineers use their skills in "safety management," "osha," and "risk management" to do their jobs. You can find more detail on essential process safety engineer responsibilities here:

Communication skills. One of the key soft skills for a process safety engineer to have is communication skills. You can see how this relates to what process safety engineers do because "health and safety engineers must be able to interpret federal and state regulations and their intent so that they can propose proper designs for specific work environments." Additionally, a process safety engineer resume shows how process safety engineers use communication skills: "developed written procedures to address hazard communications, accident reporting and investigation, respiratory protection, emergency response and contractor safety. "

Creativity. Many process safety engineer duties rely on creativity. "health and safety engineers produce designs showing potential problems and remedies for them," so a process safety engineer will need this skill often in their role. This resume example is just one of many ways process safety engineer responsibilities rely on creativity: "managed hazardous waste programs, chemical inventory, and air quality requirements. "

Problem-solving skills. This is an important skill for process safety engineers to perform their duties. For an example of how process safety engineer responsibilities depend on this skill, consider that "in designing solutions for entire organizational operations, health and safety engineers must take into account processes from more than one system at the same time." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a process safety engineer: "conducted psm audits at chemical facilities to identify risk issues and propose alternative solutions. ".

The three companies that hire the most process safety engineers are:

- Honeywell12 process safety engineers jobs

- Air Products6 process safety engineers jobs

- CF Industries6 process safety engineers jobs

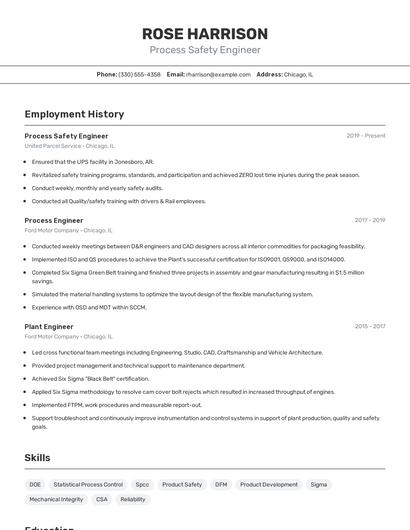

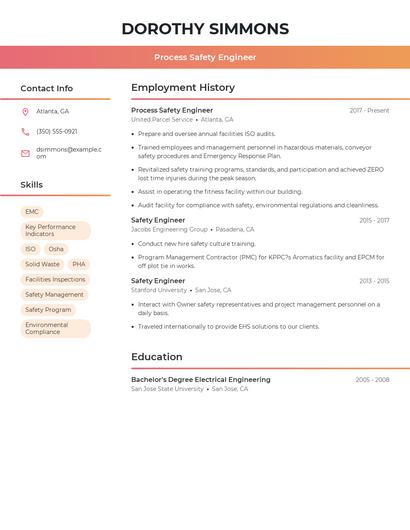

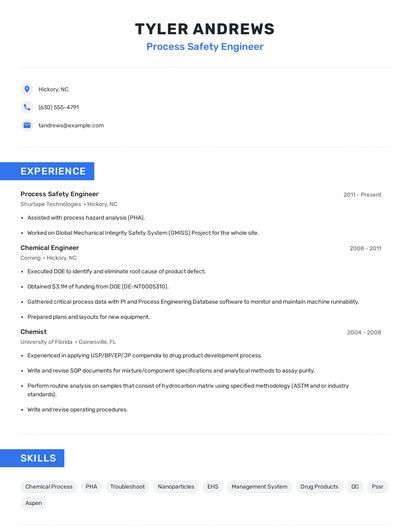

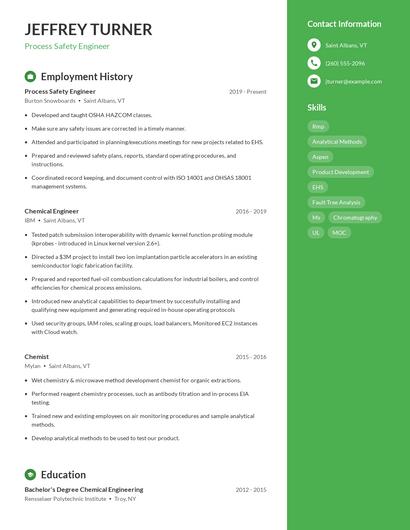

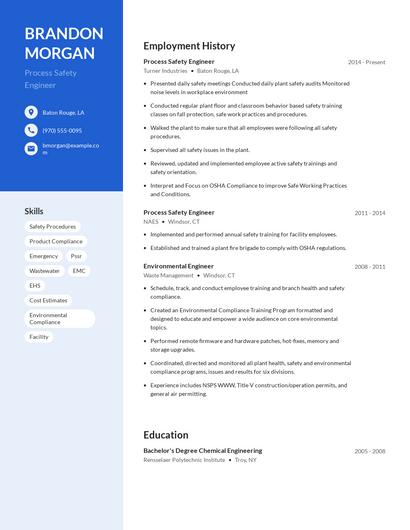

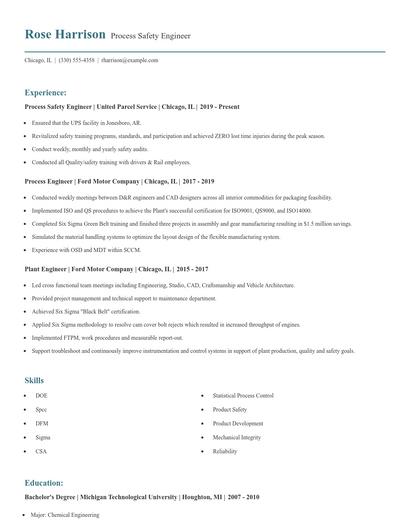

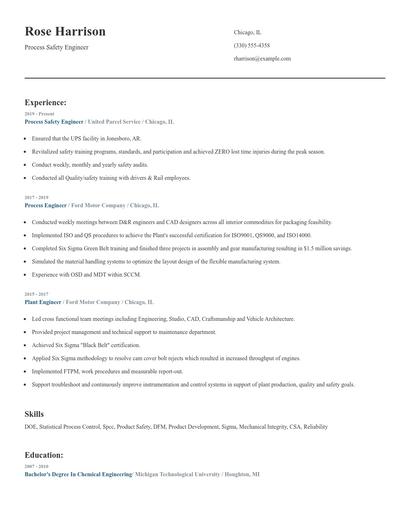

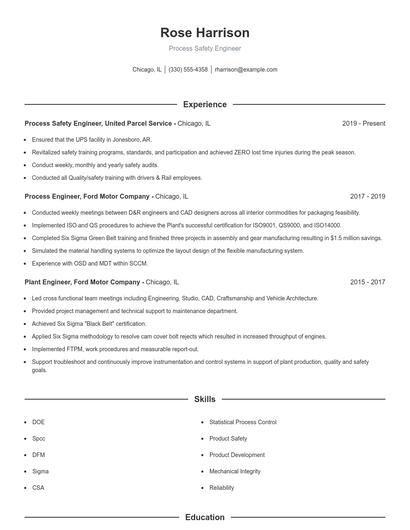

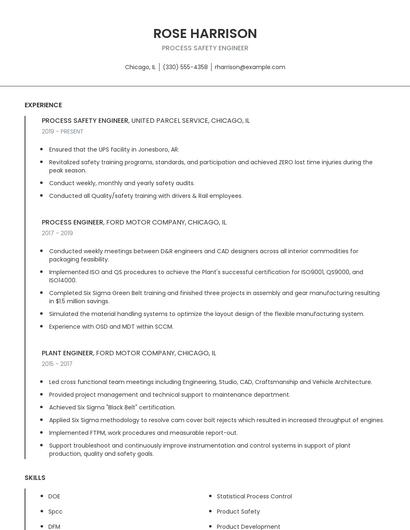

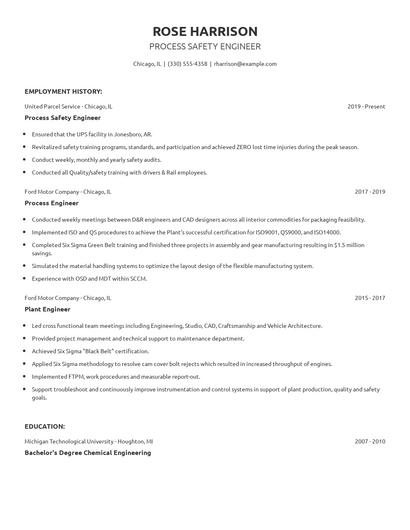

Choose from 10+ customizable process safety engineer resume templates

Build a professional process safety engineer resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your process safety engineer resume.Compare different process safety engineers

Process safety engineer vs. Ehs coordinator

An EHS coordinator develops and organizes environmental health and safety (EHS) programs and protocols in a company. They typically perform research and analysis to determine the ideal practices, gather and analyze data to identify problem areas and their corresponding solutions, spearheading information drives within the company, and coordinating with different departments. They must also perform regular inspections to ensure that departments and procedures adhere to EHS laws and regulations. Moreover, an EHS coordinator implements EHS policies and regulations, developing new ones when necessary.

These skill sets are where the common ground ends though. The responsibilities of a process safety engineer are more likely to require skills like "safety management," "risk management," "pha," and "ehs." On the other hand, a job as an ehs coordinator requires skills like "environmental health," "corrective action," "epa," and "safety committee." As you can see, what employees do in each career varies considerably.

On average, ehs coordinators reach similar levels of education than process safety engineers. Ehs coordinators are 2.1% less likely to earn a Master's Degree and 1.0% less likely to graduate with a Doctoral Degree.Process safety engineer vs. Industrial hygienist

An Industrial Hygienist plans and conducts health programs to educate employees about cleanliness, safety, and sanitation in the workplace. They investigate adequacy of ventilation, exhaust equipment, lighting, and other conditions that can affect employees' health, comfort, or efficiency.

Each career also uses different skills, according to real process safety engineer resumes. While process safety engineer responsibilities can utilize skills like "safety management," "risk management," "pha," and "mechanical integrity," industrial hygienists use skills like "environmental health," "indoor air quality," "respirators," and "corrective action."

Industrial hygienists may earn a lower salary than process safety engineers, but industrial hygienists earn the most pay in the energy industry with an average salary of $93,692. On the other hand, process safety engineers receive higher pay in the energy industry, where they earn an average salary of $124,611.industrial hygienists earn similar levels of education than process safety engineers in general. They're 2.8% more likely to graduate with a Master's Degree and 1.0% less likely to earn a Doctoral Degree.Process safety engineer vs. Ehs manager

An environmental health & safety (EHS) manager is in charge of developing and implementing safety programs for a company's workforce and work environment. Their responsibilities revolve around conducting regular inspections to ensure compliance with safety and environmental regulations, devising preventive measures, spearheading training and seminars, and investigating workplace accidents and identify causes to ensure that it would not happen again. Furthermore, as a manager, it is essential to lead and encourage the team to reach goals, all while implementing every policy and safety regulation of the company.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from process safety engineer resumes include skills like "safety management," "osha," "risk management," and "pha," whereas an ehs manager is more likely to list skills in "environmental health," "ehs management," "epa," and "corrective action. "

Ehs managers make a very good living in the technology industry with an average annual salary of $96,976. On the other hand, process safety engineers are paid the highest salary in the energy industry, with average annual pay of $124,611.ehs managers typically earn similar educational levels compared to process safety engineers. Specifically, they're 3.0% more likely to graduate with a Master's Degree, and 0.9% more likely to earn a Doctoral Degree.Process safety engineer vs. Manager, environmental and safety

An Environmental and Safety manager is responsible for overseeing environmental sustainability concerning production and manufacturing processes and mitigating nature's hazardous effects. Environmental and Safety managers evaluate the methods and resources used to produce and eliminate procedures that violate safety laws and internal regulations. They also facilitate training and programs for the employees to ensure adherence to protocols and prevent accidents during operations. An Environmental and Safety Manager must have excellent communication and leadership skills, especially in reviewing incident reports and conducting root-cause analysis to avoid reoccurrence.

Types of process safety engineer

Updated January 8, 2025