What does a die cast operator do?

Die cast operator responsibilities

Here are examples of responsibilities from real die cast operator resumes:

- Achieve enhancement in shop math: trigonometry, compound angles, and geometry.

- Operate a cnc robotic helium arc welder, under water plasma cutter and a seam welder.

- Maintain strict quality requirements using scales, calipers and micrometers.

- Operate extrusion press, load and remove dies, measure extrusion, adjust press.

- Maintain, set up, and operate a 20 pass stainless steel roll mill to PVC extrusion line.

- Assemble components into fixtures using microscope and tweezers in a microelectronics company

Die cast operator skills and personality traits

We calculated that 16% of Die Cast Operators are proficient in Trim Press, Hand Tools, and Die Cast Machine. They’re also known for soft skills such as Computer skills, Dexterity, and Mechanical skills.

We break down the percentage of Die Cast Operators that have these skills listed on their resume here:

- Trim Press, 16%

Inspect parts to make sure they are quality, trimmed parts with trim press while working as a Die Cast Operator.

- Hand Tools, 12%

Operated automatic compression/sonic weld machines and used various hand tools to assemble various components into finished product.

- Die Cast Machine, 9%

Operated die cast machinery, inspected and packaged parts and recorded measurements and documentation.

- TIP, 7%

Poured shots in sleeves by using a ladel sprayed die repaired shot arm or tip reading blue prints.

- Math, 7%

Achieved enhancement in shop math: trigonometry, compound angles, and geometry.

- Quality Standards, 6%

Inspected finished products for imperfections, assuring the product met Quality Standards.

"trim press," "hand tools," and "die cast machine" are among the most common skills that die cast operators use at work. You can find even more die cast operator responsibilities below, including:

Computer skills. To carry out their duties, the most important skill for a die cast operator to have is computer skills. Their role and responsibilities require that "metal and plastic machine workers must be able to use programmable devices, computers, and robots on the factory floor." Die cast operators often use computer skills in their day-to-day job, as shown by this real resume: "die cast machine work center operations which include robotic extractors and some computerized die cast machines. "

Mechanical skills. This is an important skill for die cast operators to perform their duties. For an example of how die cast operator responsibilities depend on this skill, consider that "these workers must be comfortable with machines and have a good understanding of how all the parts work." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a die cast operator: "conduct preliminary operational start up making mechanical and computer adjustments to the varying operational machines for the die cast process. ".

Physical strength. For certain die cast operator responsibilities to be completed, the job requires competence in "physical strength." The day-to-day duties of a die cast operator rely on this skill, as "metal and plastic machine workers must be able to secure and tighten heavy fixtures into place." For example, this snippet was taken directly from a resume about how this skill applies to what die cast operators do: "participated in iso 9000 activities, yearly physical inventory, and assisted with daily material distribution. "

The three companies that hire the most die cast operators are:

- Pace Industries14 die cast operators jobs

- Ahresty Wilmington

5 die cast operators jobs

- Brunswick4 die cast operators jobs

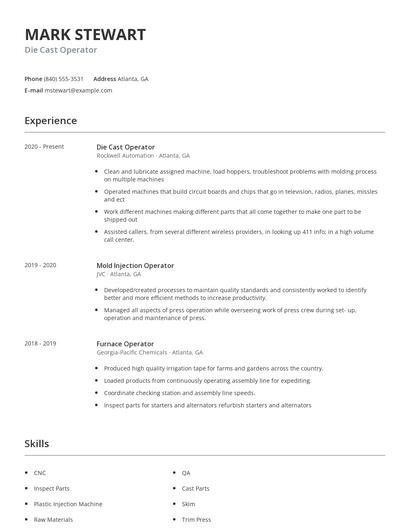

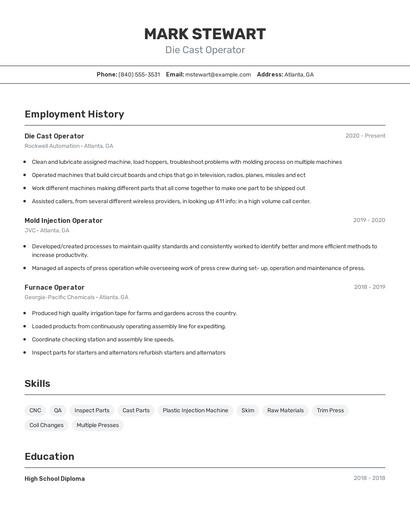

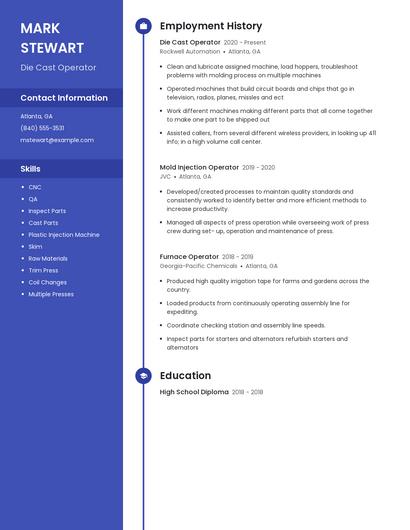

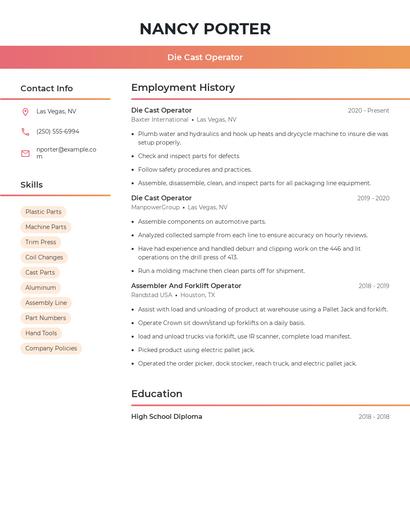

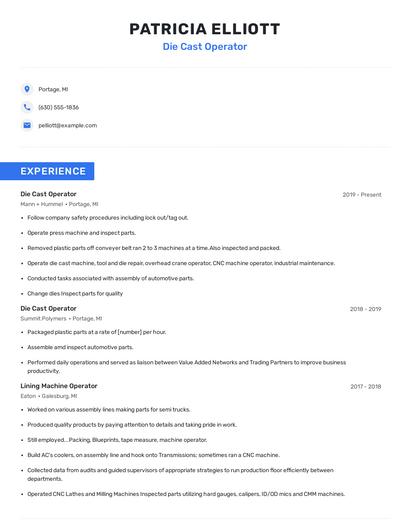

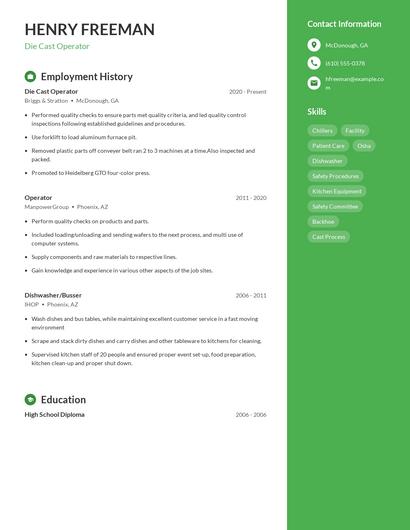

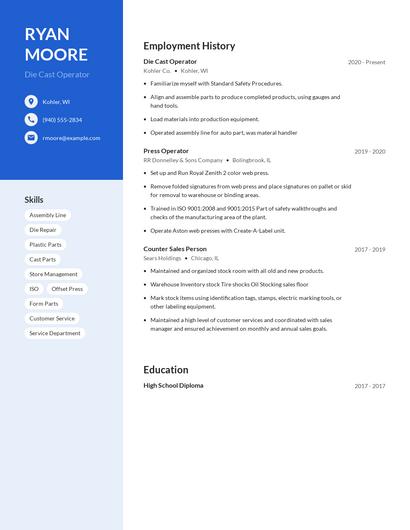

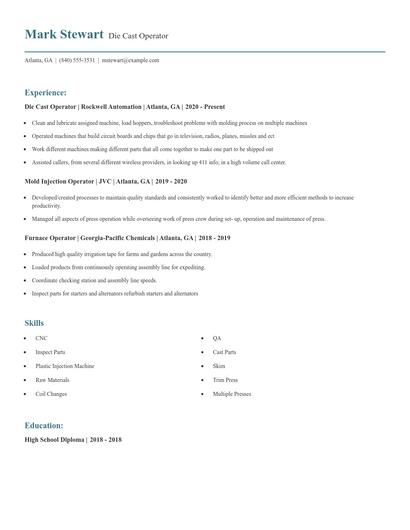

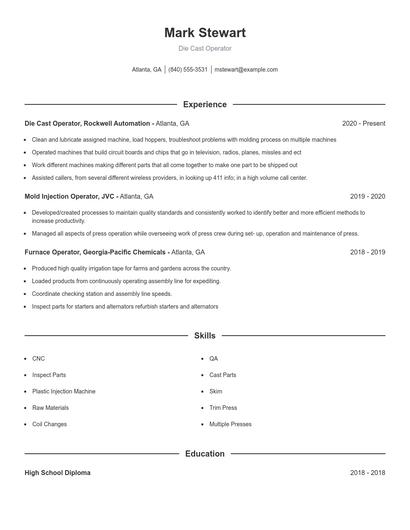

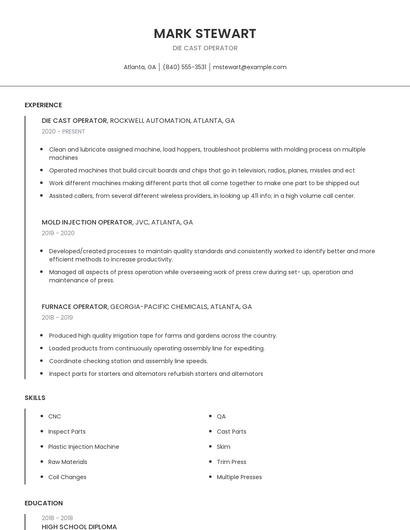

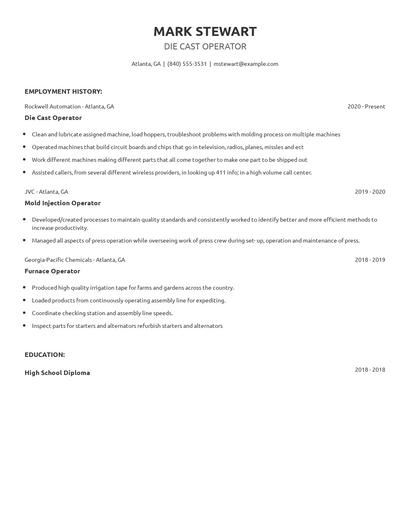

Choose from 10+ customizable die cast operator resume templates

Build a professional die cast operator resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your die cast operator resume.Compare different die cast operators

Die cast operator vs. Injection molding technician

Usually working at manufacturing facilities, an injection molding technician is in charge of setting up and designing molds and cores to ensure a smooth workflow and quality standard products. They perform installations and adjustments, troubleshoot problems, monitor systems and regulation parameters, and maintain an active communication line with co-workers. They must also conduct regular maintenance checks and perform repairs as needed. Moreover, an injection molding technician must provide technical support to staff while enforcing and promoting the company's safety policies and regulations.

While similarities exist, there are also some differences between die cast operators and injection molding technician. For instance, die cast operator responsibilities require skills such as "trim press," "die cast machine," "basic math," and "math." Whereas a injection molding technician is skilled in "preventative maintenance," "auxiliary equipment," "plastic injection," and "calipers." This is part of what separates the two careers.

Injection molding technicians earn the highest salaries when working in the automotive industry, with an average yearly salary of $54,624. On the other hand, die cast operators are paid more in the automotive industry with an average salary of $40,164.On average, injection molding technicians reach similar levels of education than die cast operators. Injection molding technicians are 2.3% more likely to earn a Master's Degree and 0.0% less likely to graduate with a Doctoral Degree.Die cast operator vs. Molding technician

A Molding Technician specializes in molding materials such as plastic or metal. They are responsible for operating and calibrating machinery, adhering to product guidelines, conducting quality inspections on finished products, lifting heavy materials, and training new workforce members. There are also instances where they must troubleshoot equipment problems, perform basic repairs, coordinate with managers or engineers, and conduct regular maintenance checks. Molding Technicians must maintain an active communication line with staff while adhering to its safety policies and regulations.

In addition to the difference in salary, there are some other key differences worth noting. For example, die cast operator responsibilities are more likely to require skills like "trim press," "die cast machine," "tip," and "aluminum castings." Meanwhile, a molding technician has duties that require skills in areas such as "preventative maintenance," "auxiliary equipment," "lean manufacturing," and "grinders." These differences highlight just how different the day-to-day in each role looks.

Molding technicians earn a higher average salary than die cast operators. But molding technicians earn the highest pay in the health care industry, with an average salary of $44,313. Additionally, die cast operators earn the highest salaries in the automotive with average pay of $40,164 annually.Average education levels between the two professions vary. Molding technicians tend to reach similar levels of education than die cast operators. In fact, they're 0.8% more likely to graduate with a Master's Degree and 0.0% more likely to earn a Doctoral Degree.Die cast operator vs. Molder

A composite technician specializes in producing and repairing composite materials, ensuring quality and efficiency. Their responsibilities include coordinating with engineers and specialists, studying designs and diagrams, operating machines and equipment, and developing strategies to optimize workflow. In a company setting, a composite technician is also in charge of producing progress reports, preparing and processing documentation, and providing technical support to staff. Furthermore, it is essential to maintain an active communication line with team members, adhering to the company's policies and regulations at all times.

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a die cast operator is likely to be skilled in "trim press," "hand tools," "die cast machine," and "basic math," while a typical molder is skilled in "sand molds," "data sheets," "foundry," and "product quality."

Molders earn the highest salary when working in the automotive industry, where they receive an average salary of $36,103. Comparatively, die cast operators have the highest earning potential in the automotive industry, with an average salary of $40,164.When it comes to education, molders tend to earn similar degree levels compared to die cast operators. In fact, they're 0.1% more likely to earn a Master's Degree, and 0.1% more likely to graduate with a Doctoral Degree.Die cast operator vs. Composite technician

Types of die cast operator

Updated January 8, 2025