What does a materials program manager do?

In the manufacturing industry, a materials program manager oversees a company's supply chain operations to ensure the quality and efficient delivery of materials needed to manufacture goods. Among their responsibilities include managing different teams, setting goals and timelines, liaising with internal and external parties, building positive relationships with suppliers and distributors, and developing strategies to optimize program operations. They must also address issues and concerns, resolving them promptly and efficiently. Moreover, as a manager, it is essential to lead and encourage the workforce to reach goals while implementing the company's policies and regulations.

Materials program manager responsibilities

Here are examples of responsibilities from real materials program manager resumes:

- Manage key commodities such as displays, camera modules and sensors, batteries and other components.

- Manage and develop multimillion-dollar programs as capture lead for DoD subcontracts and project submissions.

- Negotiate and manage contracts for domestic, international transportation custom brokers, freight forwarders and other logistics services.

- Manage implementation of referrals, coordinate assignment of new physicians and create support network for transitioning patients during clinic closure.

- Lead and implement direct ship project for OEM customers.

- Utilize BaaN ERP system to perform both new product and sustainment product master scheduling.

- Generate and maintain MRP demand to source materials in order to meet critical schedule milestones.

- Establish material and vendor tracking system to coordinate custom vendor requests from major OEM customer.

- Streamline communications within the company through developing and executing the enterprise resource planning (ERP) system.

- Provide the support necessary to ensure the proper time phase flow of material from MRP release to material receipt.

- Develop cost reduced, HVM supportable BOM and a material support plan to mitigate risk to HVM material supply line.

- Used reverse logistics methodologies to re-allocate serviceable property and equipment for future use on projects.

- Monitor development budget adherence and BOM costs with focus on configuration commonality and qualification build reduction.

- Coordinate partnership efforts with other state and local agencies to facilitate oversight and technical assistance relate to private school compliance activities.

- Developed/Maintain SOX narratives pertinent to purchasing/accounts payable.

Materials program manager skills and personality traits

We calculated that 15% of Materials Program Managers are proficient in Supply Chain, Program Management, and Supplier Management. They’re also known for soft skills such as Analytical skills, Decisionmaking skills, and Math skills.

We break down the percentage of Materials Program Managers that have these skills listed on their resume here:

- Supply Chain, 15%

Supply chain risk management including proactive identification, management and up-front mitigation of all materiel risks on programs.

- Program Management, 8%

Program Management role for material/ subcontracted services cost segments for commercial and government-funded Satellite Component Programs.

- Supplier Management, 6%

Key operational areas included supplier management and contract pricing adherence.

- Chain Management, 6%

Promoted strategic Supply Chain Management techniques to replace tactical buying; Championed Lean Manufacturing concepts to improve throughput/reduce waste.

- Sigma, 5%

Managed program material requirements to support manufacturing operations Initiated and monitored materials and services procurement activities Completed Six Sigma Specialist training

- MRP, 5%

Provide the support necessary to ensure the proper time phased flow of material from MRP release to material receipt.

Common skills that a materials program manager uses to do their job include "supply chain," "program management," and "supplier management." You can find details on the most important materials program manager responsibilities below.

Analytical skills. The most essential soft skill for a materials program manager to carry out their responsibilities is analytical skills. This skill is important for the role because "when evaluating suppliers, purchasing managers and buyers and purchasing agents must analyze their options and choose a supplier with the best combination of price, quality, delivery, or service." Additionally, a materials program manager resume shows how their duties depend on analytical skills: "utilized oracle erp system and reflex database. "

Decisionmaking skills. Another essential skill to perform materials program manager duties is decisionmaking skills. Materials program managers responsibilities require that "purchasing managers and buyers and purchasing agents must have the ability to make informed and timely decisions, choosing products that they think will sell." Materials program managers also use decisionmaking skills in their role according to a real resume snippet: "led the make-buy decisionmaking process and supply chain definition for all new components, sub-assemblies and assemblies of new products. "

Math skills. Another skill that relates to the job responsibilities of materials program managers is math skills. This skill is critical to many everyday materials program manager duties, as "purchasing managers and buyers and purchasing agents must possess math skills." This example from a resume shows how this skill is used: "improved engineering resource utilization with applied statistics, and established earned value management (evm) project metrics. "

Negotiating skills. materials program manager responsibilities often require "negotiating skills." The duties that rely on this skill are shown by the fact that "purchasing managers and buyers and purchasing agents often must negotiate the terms of a contract with a supplier." This resume example shows what materials program managers do with negotiating skills on a typical day: "saved $200,000 through negotiating and selecting freight service without compromising logistics activities. "

The three companies that hire the most materials program managers are:

- Raytheon Technologies46 materials program managers jobs

- AECOM11 materials program managers jobs

- Amazon9 materials program managers jobs

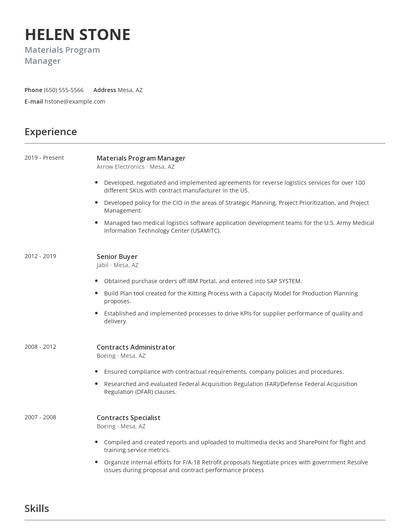

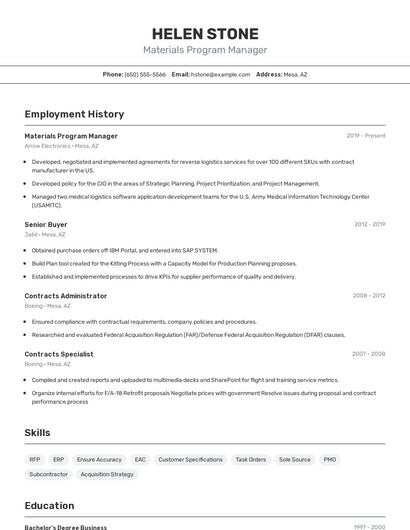

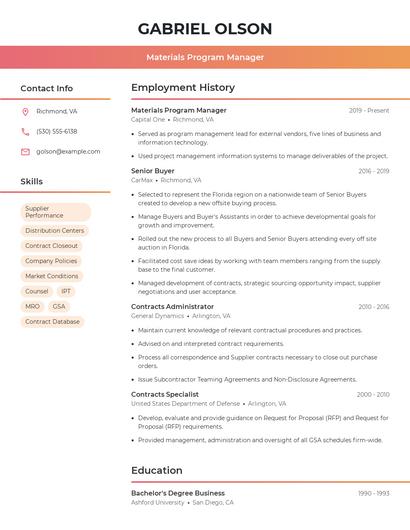

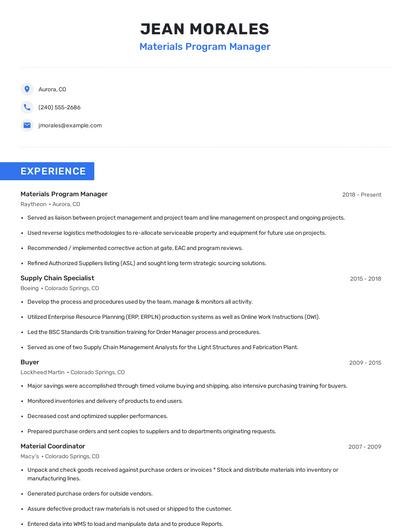

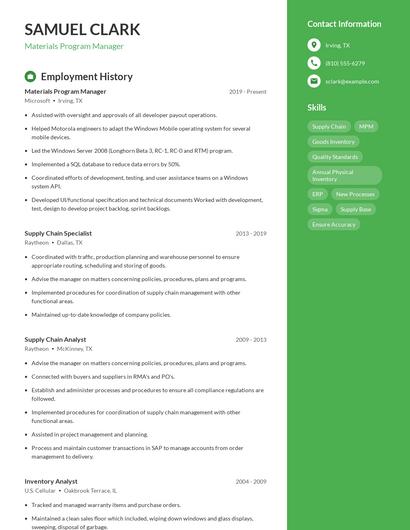

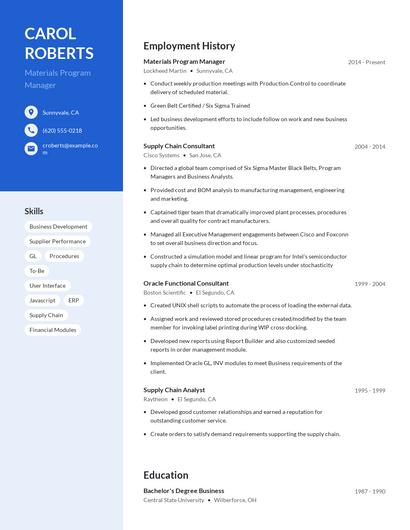

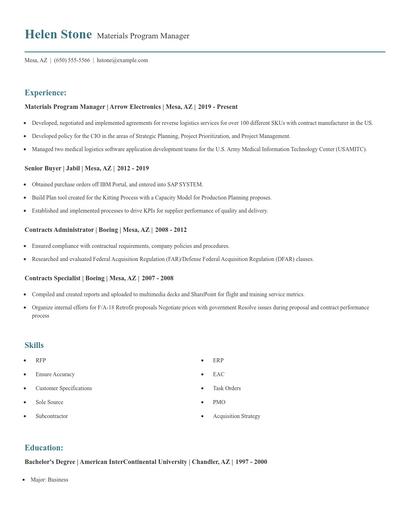

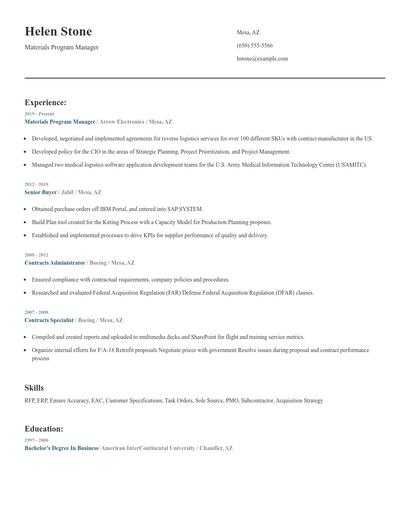

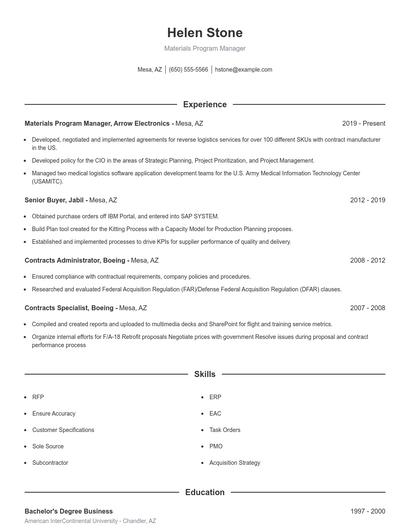

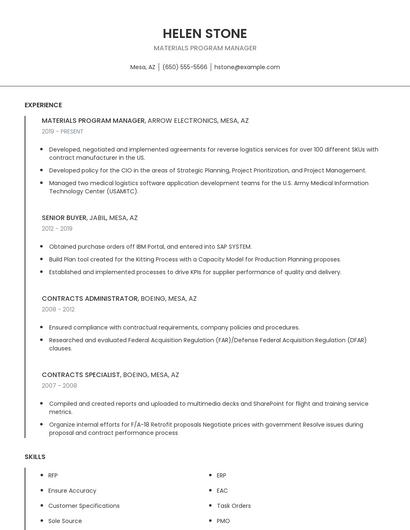

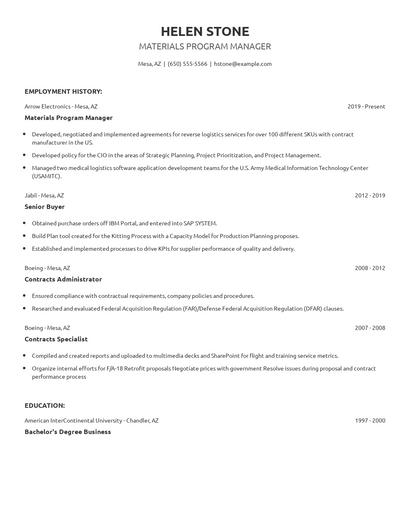

Choose from 10+ customizable materials program manager resume templates

Build a professional materials program manager resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your materials program manager resume.Compare different materials program managers

Materials program manager vs. Supply officer

A director of sourcing is an executive professional who supervises a team of sourcing managers that manages the supply portfolio of a company to ensure spending transparency. This director is required to direct overseas factory meetings weekly to review product development and optimize the company's overall supply chain. The director must lead cross-functional process improvement teams to enhance performance and improve product quality. This director must also maintain excellent working relationships with vendors to ensure the success of their projects.

These skill sets are where the common ground ends though. The responsibilities of a materials program manager are more likely to require skills like "supply chain," "program management," "supplier management," and "sigma." On the other hand, a job as a supply officer requires skills like "logistics support," "financial management," "food service," and "property accountability." As you can see, what employees do in each career varies considerably.

The education levels that supply officers earn slightly differ from materials program managers. In particular, supply officers are 5.5% less likely to graduate with a Master's Degree than a materials program manager. Additionally, they're 1.0% less likely to earn a Doctoral Degree.Materials program manager vs. Director of sourcing

A director of purchasing oversees the procedures related to buying resources and supplies, directing operations from planning to execution while adhering to standards and company policies. They primarily perform research and assessments to understand project needs in terms of price, quality, and delivery time. They also identify ideal suppliers, negotiate deals, and build positive business relationships. Additionally, a director of purchasing has the authority to make significant decisions, delegate responsibilities among staff, oversee employment procedures within the department, and solve issues and concerns when any arise.

Each career also uses different skills, according to real materials program manager resumes. While materials program manager responsibilities can utilize skills like "program management," "supplier management," "chain management," and "mrp," directors of sourcing use skills like "continuous improvement," "project management," "process improvement," and "supplier performance."

On average, directors of sourcing earn a higher salary than materials program managers. Some industries support higher salaries in each profession. Interestingly enough, directors of sourcing earn the most pay in the retail industry with an average salary of $139,795. Whereas materials program managers have higher pay in the manufacturing industry, with an average salary of $106,730.Average education levels between the two professions vary. Directors of sourcing tend to reach similar levels of education than materials program managers. In fact, they're 0.4% more likely to graduate with a Master's Degree and 1.0% less likely to earn a Doctoral Degree.Materials program manager vs. Director of purchasing

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a materials program manager is likely to be skilled in "program management," "supplier management," "sigma," and "opportunity management," while a typical director of purchasing is skilled in "purchase orders," "vendor relations," "supplier performance," and "direct reports."

Directors of purchasing earn the highest salary when working in the manufacturing industry, where they receive an average salary of $119,626. Comparatively, materials program managers have the highest earning potential in the manufacturing industry, with an average salary of $106,730.directors of purchasing typically earn similar educational levels compared to materials program managers. Specifically, they're 4.9% less likely to graduate with a Master's Degree, and 0.6% less likely to earn a Doctoral Degree.Materials program manager vs. Manager of purchasing & materials

Types of materials program manager

Updated January 8, 2025