What does a set-up mechanic do?

Set-up mechanic responsibilities

Here are examples of responsibilities from real set-up mechanic resumes:

- Manage daily scheduling of production workload to be setup and run on machinery.

- Audit production lines to ensure quality is being meet as well as FDA standards are being follow.

- Repair and produce product using extrusion equipment ie, Reifienhausen and PTI.

- Set up and run CNC mills for medical and various other manufacture parts.

- Repair, maintain, troubleshoot, and perform PMs on conveyor systems control by PLC and pneumatic control switches.

- Perform training /maintenance techniques on a variety of equipment including furnaces, vacuum pumps, high-pressure washers and CNC machining equipment.

- Used various tools including micrometers, calipers, and comparators to ensure parts are to exact specification while holding strict tolerances.

- Coordinate activities between operations, maintenance, scheduling, QA, etc.

- Work hand in hand with QA techs on daily bases to keep parts in tolerance per engineering prints.

- Participate in Kaizen events so to ensure continuous improvement within manufacturing operation.

Set-up mechanic skills and personality traits

We calculated that 12% of Set-Up Mechanics are proficient in FDA, GMP, and Safety Procedures. They’re also known for soft skills such as Troubleshooting skills, Manual dexterity, and Mechanical skills.

We break down the percentage of Set-Up Mechanics that have these skills listed on their resume here:

- FDA, 12%

Assisted in LINE-VALIDATIONS for FDA approval for drug related products.

- GMP, 11%

Perform timely electrical and mechanical repairs complying with Food Industry Safety Standards and GMP regulations.

- Safety Procedures, 10%

Ensured all safety procedures were followed with strict adherence.

- Electrical Troubleshooting, 9%

Performed electrical troubleshooting at different control panels in the production area.

- Preventive Maintenance, 9%

Maintain all equipment and facilities in good condition using preventive maintenance and calibration schedule.

- Safety Standards, 8%

Plan, schedule, assign, and oversee machine operators to ensure attainment of production, quality and safety standards.

Most set-up mechanics use their skills in "fda," "gmp," and "safety procedures" to do their jobs. You can find more detail on essential set-up mechanic responsibilities here:

Troubleshooting skills. To carry out their duties, the most important skill for a set-up mechanic to have is troubleshooting skills. Their role and responsibilities require that "industrial machinery mechanics, machinery maintenance workers, and millwrights must observe, diagnose, and fix problems that a machine may be having." Set-up mechanics often use troubleshooting skills in their day-to-day job, as shown by this real resume: "perform industrial maintenance such as setting up machinery, basic changeovers, moehwald calibrators, troubleshooting and program changes. "

Manual dexterity. Another soft skill that's essential for fulfilling set-up mechanic duties is manual dexterity. The role rewards competence in this skill because "industrial machinery mechanics, machinery maintenance workers, and millwrights must have a steady hand and good hand–eye coordination when handling very small parts." According to a set-up mechanic resume, here's how set-up mechanics can utilize manual dexterity in their job responsibilities: "managed 5 or more production workers when assigned to manual production lines. "

Mechanical skills. This is an important skill for set-up mechanics to perform their duties. For an example of how set-up mechanic responsibilities depend on this skill, consider that "industrial machinery mechanics, machinery maintenance workers, and millwrights use technical manuals and sophisticated diagnostic equipment to figure out why machines are not working." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a set-up mechanic: "repaired and maintained mechanical production lines to ensure maximum productivity. ".

The three companies that hire the most set-up mechanics are:

- Eaton12 set-up mechanics jobs

- Amneal Pharmaceuticals6 set-up mechanics jobs

- Novolex5 set-up mechanics jobs

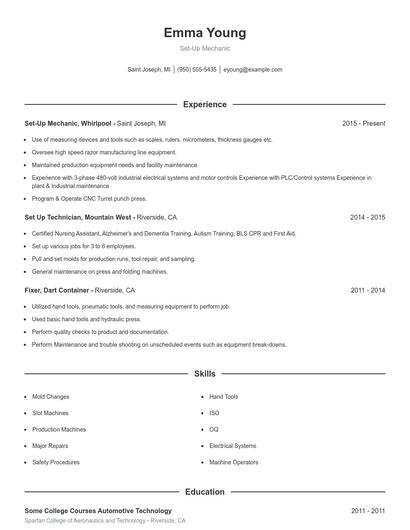

Choose from 10+ customizable set-up mechanic resume templates

Build a professional set-up mechanic resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your set-up mechanic resume.Compare different set-up mechanics

Set-up mechanic vs. Chemical processing equipment repairer

An industrial maintenance/electrician specializes in installing and maintaining electrical systems in different establishments. Responsibilities usually include performing inspections to assess electrical damages on systems, understanding blueprints, troubleshooting problems, replacing or fixing components, and conducting regular maintenance checks to ensure that electrical systems function smoothly and efficiently. Moreover, an industrial maintenance/electrician may also upgrade facilities, provide technical support to staff, and train new members of the workforce while enforcing and promoting the company's safety standards and regulations.

These skill sets are where the common ground ends though. The responsibilities of a set-up mechanic are more likely to require skills like "fda," "gmp," "safety procedures," and "electrical troubleshooting." On the other hand, a job as a chemical processing equipment repairer requires skills like "decontamination equipment," "damage assessment," "mos," and "ait." As you can see, what employees do in each career varies considerably.

On average, chemical processing equipment repairers reach similar levels of education than set-up mechanics. Chemical processing equipment repairers are 1.1% more likely to earn a Master's Degree and 0.5% less likely to graduate with a Doctoral Degree.Set-up mechanic vs. Industrial maintenance/electrician

Each career also uses different skills, according to real set-up mechanic resumes. While set-up mechanic responsibilities can utilize skills like "fda," "gmp," "safety procedures," and "safety standards," industrial maintenance/electricians use skills like "ac dc," "electrical equipment," "lockout tagout," and "test equipment."

On average, industrial maintenance/electricians earn a higher salary than set-up mechanics. Some industries support higher salaries in each profession. Interestingly enough, industrial maintenance/electricians earn the most pay in the automotive industry with an average salary of $59,754. Whereas set-up mechanics have higher pay in the health care industry, with an average salary of $47,311.In general, industrial maintenance/electricians achieve similar levels of education than set-up mechanics. They're 2.7% more likely to obtain a Master's Degree while being 0.5% less likely to earn a Doctoral Degree.Set-up mechanic vs. Machine repairman

There are many key differences between these two careers, including some of the skills required to perform responsibilities within each role. For example, a set-up mechanic is likely to be skilled in "fda," "gmp," "safety procedures," and "preventive maintenance," while a typical machine repairman is skilled in "preventative maintenance," "cranes," "drill presses," and "building maintenance."

Machine repairmen typically earn similar educational levels compared to set-up mechanics. Specifically, they're 0.6% less likely to graduate with a Master's Degree, and 0.5% less likely to earn a Doctoral Degree.Set-up mechanic vs. Repairman

Types of set-up mechanic

Updated January 8, 2025