What does a maintenance repairman do?

Maintenance repairman responsibilities

Here are examples of responsibilities from real maintenance repairman resumes:

- Perform and manage routine building maintenance tasks, including carpentry, electrical, plumbing, and minor HVAC repair and maintenance.

- Replace a/c filters, and troubleshoot any residential complaints for items broken.

- Sole responsibilities include sustaining organization and cleanliness as well as developing and maintaining positive relationship with management and residents.

- Change out pulleys and belts.

- Require innovation and manual dexterity while using small tools in confine conditions to repair damage facilities.

Maintenance repairman skills and personality traits

We calculated that 9% of Maintenance Repairmen are proficient in Plumbing, Preventative Maintenance, and Hand Tools. They’re also known for soft skills such as Customer-service skills, Dexterity, and Troubleshooting skills.

We break down the percentage of Maintenance Repairmen that have these skills listed on their resume here:

- Plumbing, 9%

Maintained and repaired Restaurant equipment including some plumbing, welding, electrical and refrigeration.

- Preventative Maintenance, 9%

Assisted in development of preventative maintenance program.

- Hand Tools, 8%

Lubricate machinery, vehicles, and equipment, and perform minor repairs and adjustments, using hand tools.

- GRASS, 6%

Follow planned landscaping designs to determine where to lay sod, sow grass, or plant flowers and foliage.

- General Maintenance, 5%

General maintenance as needed for loaders, crushers, and conveyors.

- HVAC, 5%

General building maintenance, electrical repair and HVAC Maintenance

Most maintenance repairmen use their skills in "plumbing," "preventative maintenance," and "hand tools" to do their jobs. You can find more detail on essential maintenance repairman responsibilities here:

Customer-service skills. To carry out their duties, the most important skill for a maintenance repairman to have is customer-service skills. Their role and responsibilities require that "these workers interact with customers on a regular basis." Maintenance repairmen often use customer-service skills in their day-to-day job, as shown by this real resume: "provided maintenance and repair services to commercial and residential customers including building, painting, plumbing and electric. "

Dexterity. Another essential skill to perform maintenance repairman duties is dexterity. Maintenance repairmen responsibilities require that "many repair and maintenance tasks, such as repairing small devices, connecting or attaching components, and using hand tools, require a steady hand and good hand–eye coordination." Maintenance repairmen also use dexterity in their role according to a real resume snippet: "perform plumbing, electrical, hvac, welding/brazing/cutting, overhead crane and forklift operation, and building grounds maintenance. "

Troubleshooting skills. This is an important skill for maintenance repairmen to perform their duties. For an example of how maintenance repairman responsibilities depend on this skill, consider that "workers find, diagnose, and repair problems." This excerpt from a resume also shows how vital it is to everyday roles and responsibilities of a maintenance repairman: "conducted routine hvac and electrical troubleshooting, alerted chief engineer and property manager of problematic issues, and recommended solutions. ".

The three companies that hire the most maintenance repairmans are:

- East Stroudsburg University5 maintenance repairmen jobs

- ASARCO3 maintenance repairmen jobs

- Commonwealth Of Pennsylvania3 maintenance repairmen jobs

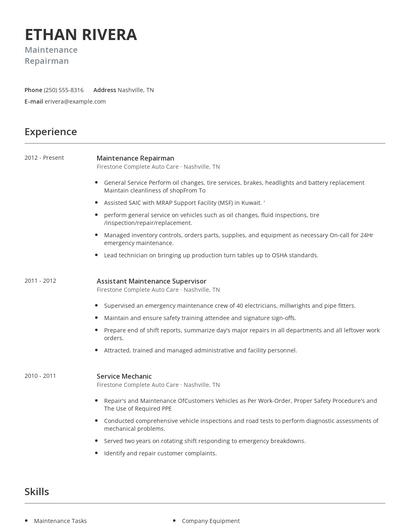

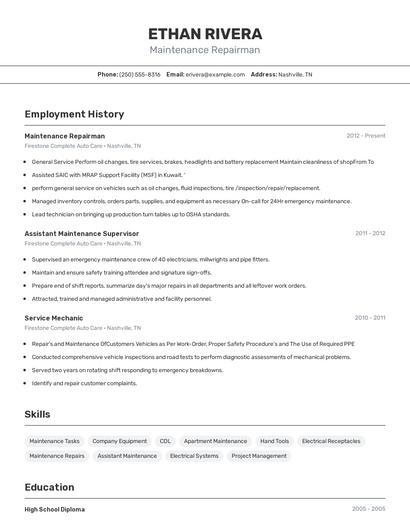

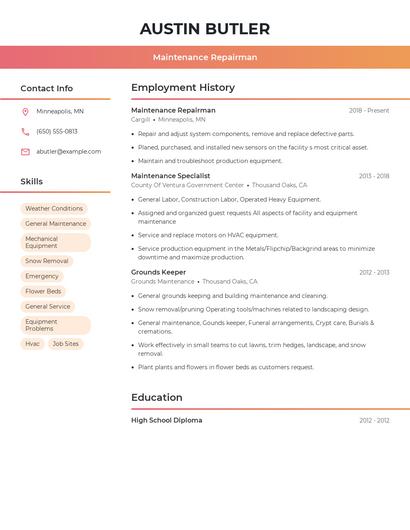

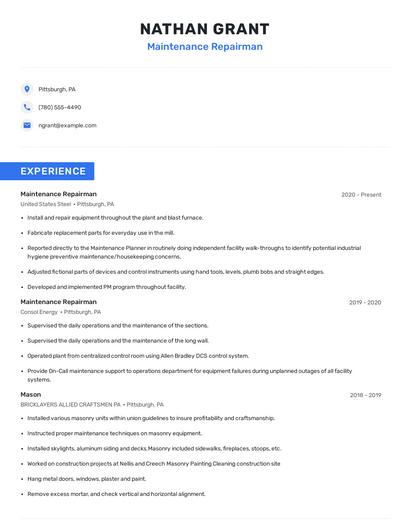

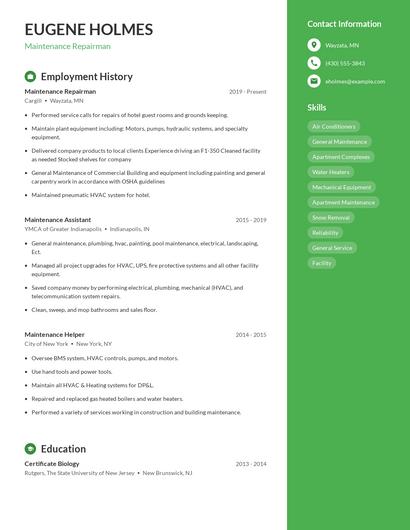

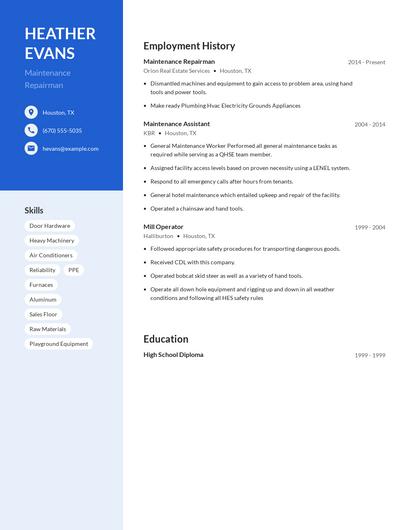

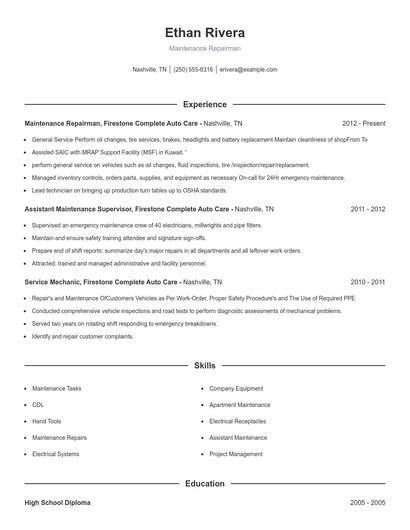

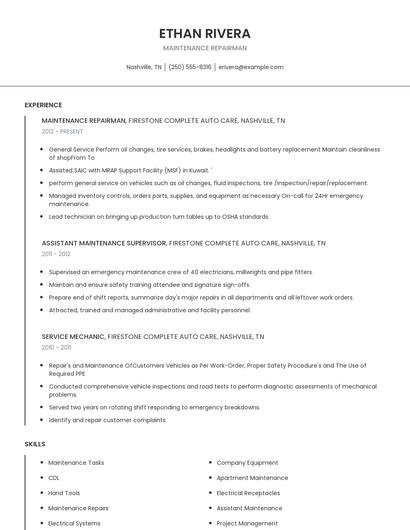

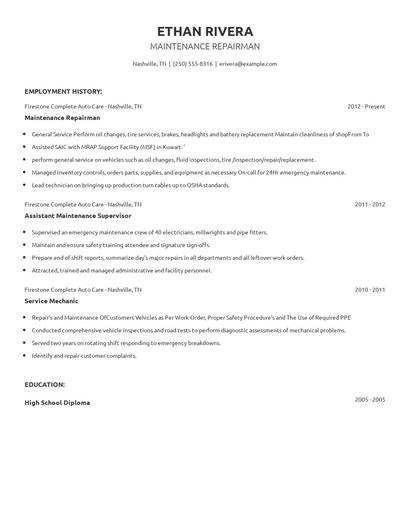

Choose from 10+ customizable maintenance repairman resume templates

Build a professional maintenance repairman resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your maintenance repairman resume.Compare different maintenance repairmen

Maintenance repairman vs. Operations and maintenance technician

Operations and maintenance technicians are skilled professionals who are responsible for conducting preventive maintenance of all equipment used in the operation of an organization. These technicians are required to ensure that their facilities are always operational by performing inspections and documenting the operating conditions of their equipment. They must utilize numerous power and hand tools so that they can perform all preventive maintenance and diagnose mechanical problems. Operations and maintenance technicians must also monitor the operation of plan equipment to ensure that employees are following the proper maintenance and safety procedures.

These skill sets are where the common ground ends though. The responsibilities of a maintenance repairman are more likely to require skills like "maintenance repairs," "roofing," "troubleshoot," and "asphalt." On the other hand, a job as an operations and maintenance technician requires skills like "plant operations," "plant equipment," "cleanliness," and "windows." As you can see, what employees do in each career varies considerably.

Operations and maintenance technicians earn the highest salaries when working in the energy industry, with an average yearly salary of $60,926. On the other hand, maintenance repairmen are paid more in the manufacturing industry with an average salary of $33,526.The education levels that operations and maintenance technicians earn slightly differ from maintenance repairmen. In particular, operations and maintenance technicians are 0.7% more likely to graduate with a Master's Degree than a maintenance repairman. Additionally, they're 0.0% less likely to earn a Doctoral Degree.Maintenance repairman vs. Maintenance technician supervisor

A maintenance technician supervisor is responsible for monitoring the facilities within the company premises, including office equipment and machinery, ensuring performance efficiency for smooth daily operations. Maintenance technician supervisors may perform troubleshooting for defective equipment, call for repairs, or replace the items as needed. They also manage the maintenance staff performance, delegate tasks, and enforce strict adherence to the company's safety procedures. A maintenance technician supervisor must be highly organizational and communicative, especially on maintaining building systems and inventories and training maintenance staff.

In addition to the difference in salary, there are some other key differences worth noting. For example, maintenance repairman responsibilities are more likely to require skills like "hand tools," "grass," "general maintenance," and "ladders." Meanwhile, a maintenance technician supervisor has duties that require skills in areas such as "customer service," "osha," "cmms," and "air compressors." These differences highlight just how different the day-to-day in each role looks.

Maintenance technician supervisors may earn a higher salary than maintenance repairmen, but maintenance technician supervisors earn the most pay in the professional industry with an average salary of $44,450. On the other hand, maintenance repairmen receive higher pay in the manufacturing industry, where they earn an average salary of $33,526.Average education levels between the two professions vary. Maintenance technician supervisors tend to reach similar levels of education than maintenance repairmen. In fact, they're 1.8% more likely to graduate with a Master's Degree and 0.0% more likely to earn a Doctoral Degree.Maintenance repairman vs. Repairman

An equipment maintenance technician is responsible for ensuring the stability and efficiency of all production tools and equipment to support smooth business functions and operations. Equipment maintenance technicians conduct regular maintenance for optimization, repair defective components, and inspect equipment parts to identify possible upgrades and replacements. They also assemble equipment and machinery, requiring them to have excellent mechanical and critical-thinking skills to analyze schematics and blueprints accurately. An equipment maintenance technician must be highly communicative and organizational, especially in adhering to the highest safety standards and protocols during operations.

The required skills of the two careers differ considerably. For example, maintenance repairmen are more likely to have skills like "plumbing," "preventative maintenance," "hand tools," and "grass." But a repairman is more likely to have skills like "safety rules," "pry bars," "preventive maintenance," and "aar."

Repairmen earn the best pay in the technology industry, where they command an average salary of $44,834. Maintenance repairmen earn the highest pay from the manufacturing industry, with an average salary of $33,526.repairmen typically earn similar educational levels compared to maintenance repairmen. Specifically, they're 0.1% more likely to graduate with a Master's Degree, and 0.0% more likely to earn a Doctoral Degree.Maintenance repairman vs. Equipment maintenance technician

Types of maintenance repairman

Updated January 8, 2025