What does a first-line production supervisor do?

First-line production supervisor responsibilities

Here are examples of responsibilities from real first-line production supervisor resumes:

- Lead Kaizen identifying changeover/set-up issues.

- Execute leadership and supervision skills in guiding daily operations of eight staff and training 10 personnel in meteorological and navigational systems.

- Utilize TPS techniques to standardize process/methods, identify waste, methodically eliminate waste and standardize the new process/ methods.

First-line production supervisor skills and personality traits

We calculated that 24% of First-Line Production Supervisors are proficient in Safety Procedures, Safety Policies, and Production Processes.

We break down the percentage of First-Line Production Supervisors that have these skills listed on their resume here:

- Safety Procedures, 24%

Provided supervision and guided regular employee training on equipment operations, work flow, and safety procedures.

- Safety Policies, 12%

Ensured adherence to established operations and safety policies and procedures.

- Production Processes, 9%

Cross trained and certified employees in multiple production processes, which improved productivity, employee utilization and manufacturing flexibility.

- Lean Manufacturing, 8%

Trained in lean manufacturing using tools for continuous improvements such as kaizen and 5s.Reporting to the plant manager.

- Production Schedules, 6%

Maintained work orders via computer documentation and studied production schedules and estimated worker-hour requirements for completion of job assignments.

- FDA, 5%

Participated in FDA audits of the manufacturing facility.

Common skills that a first-line production supervisor uses to do their job include "safety procedures," "safety policies," and "production processes." You can find details on the most important first-line production supervisor responsibilities below.

The three companies that hire the most first-line production supervisors are:

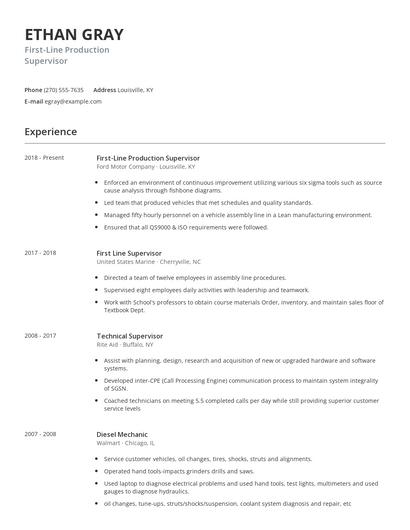

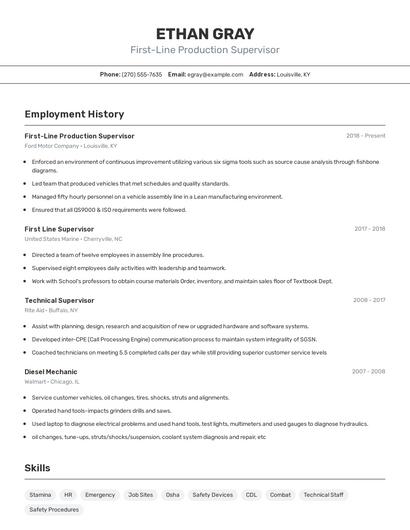

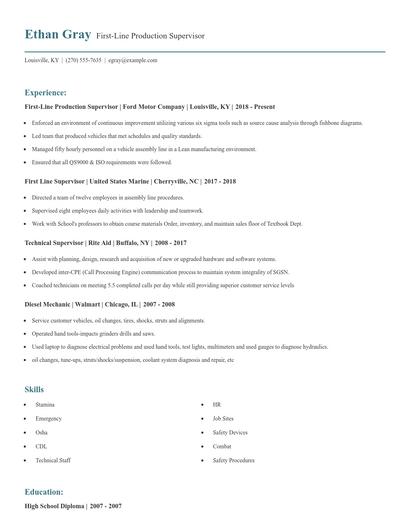

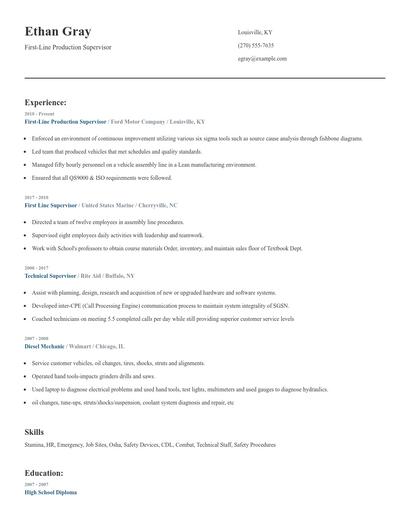

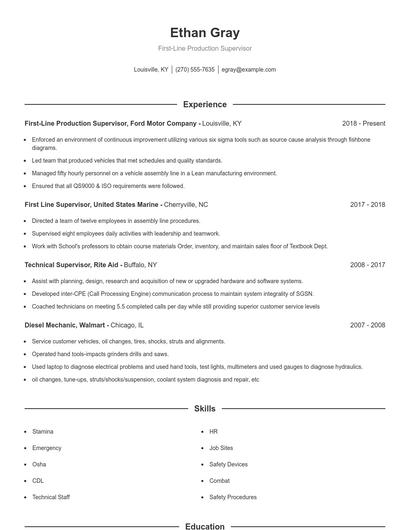

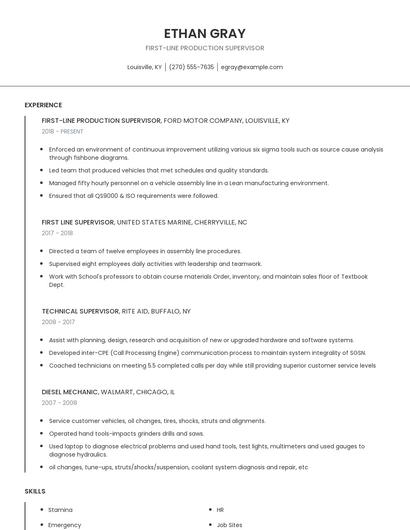

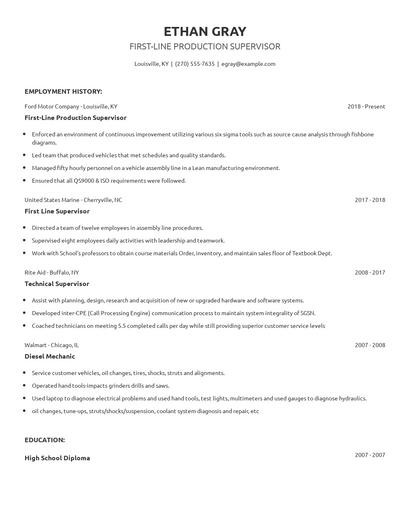

Choose from 10+ customizable first-line production supervisor resume templates

Build a professional first-line production supervisor resume in minutes. Our AI resume writing assistant will guide you through every step of the process, and you can choose from 10+ resume templates to create your first-line production supervisor resume.Compare different first-line production supervisors

First-line production supervisor vs. Production line leader

The job of a materials supervisor is to oversee the shipping, receiving, handling, and warehousing of materials. You will supervise the transport of materials and ensure that the material needs of an organization are met. Typical job duties include overseeing the daily business operations of the group, ensuring best practices in safety, productivity, housekeeping. The supervisors ensure that attendance is being followed and monitoring routine operations in materials management, including logistics and planning. As a materials supervisor, you are also expected to mentor team members for professional and personal development.

There are some key differences in the responsibilities of each position. For example, first-line production supervisor responsibilities require skills like "inspectors," "safety policies," "production processes," and "lean manufacturing." Meanwhile a typical production line leader has skills in areas such as "team work," "quality checks," "cleanliness," and "quality standards." This difference in skills reveals the differences in what each career does.

Production line leaders earn the highest salaries when working in the automotive industry, with an average yearly salary of $44,299. On the other hand, first-line production supervisors are paid more in the manufacturing industry with an average salary of $70,060.On average, production line leaders reach similar levels of education than first-line production supervisors. Production line leaders are 0.5% more likely to earn a Master's Degree and 0.3% more likely to graduate with a Doctoral Degree.First-line production supervisor vs. Materials supervisor

A 3rd shift supervisor is responsible for monitoring the operations and staff performance of a specific shift. 3rd shift supervisors strategize on effective business techniques to maximize staff's productivity and improve customers' experience. They also analyze sales reports, resolve discrepancies, and identify business opportunities that would generate more resources for revenues and increase the company's profitability. A 3rd shift supervisor addresses customers' inquiries and concerns, as well as resolving their complaints about services timely and accurately.

Each career also uses different skills, according to real first-line production supervisor resumes. While first-line production supervisor responsibilities can utilize skills like "inspectors," "safety policies," "production processes," and "production operations," materials supervisors use skills like "logistics," "shipping receiving," "mrp," and "corrective action."

Materials supervisors earn a higher average salary than first-line production supervisors. But materials supervisors earn the highest pay in the manufacturing industry, with an average salary of $71,036. Additionally, first-line production supervisors earn the highest salaries in the manufacturing with average pay of $70,060 annually.Average education levels between the two professions vary. Materials supervisors tend to reach higher levels of education than first-line production supervisors. In fact, they're 7.3% more likely to graduate with a Master's Degree and 0.3% more likely to earn a Doctoral Degree.First-line production supervisor vs. 3rd shift supervisor

A 2nd shift supervisor is responsible for supporting the operations of a department, managing the staff's performance, and assisting the team in achieving maximum productivity. They provide high-quality services for the customers by responding to their inquiries and concerns and resolving complaints. They also implement strategic procedures to achieve production goals, as well as identifying business opportunities that would drive more revenue resources and profits for the company. A 2nd shift supervisor also assists in handling the department's budget, ensuring adequate allocation to support operations.

Some important key differences between the two careers include a few of the skills necessary to fulfill the responsibilities of each. Some examples from first-line production supervisor resumes include skills like "inspectors," "safety policies," "production processes," and "production operations," whereas a 3rd shift supervisor is more likely to list skills in "customer service," "basic math," "pallet jack," and "cleanliness. "

3rd shift supervisors earn the highest salary when working in the transportation industry, where they receive an average salary of $35,104. Comparatively, first-line production supervisors have the highest earning potential in the manufacturing industry, with an average salary of $70,060.3rd shift supervisors typically earn similar educational levels compared to first-line production supervisors. Specifically, they're 1.3% more likely to graduate with a Master's Degree, and 0.2% more likely to earn a Doctoral Degree.First-line production supervisor vs. 2nd shift supervisor

Types of first-line production supervisor

Updated January 8, 2025